5005 Aluminum Coil - One Bar Diamond Aluminum Checker Plate with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of One Bar Diamond Aluminum Checker Plate Description:

Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of One Bar Diamond Aluminum Checker Plate:

PVC Protect Film

Waterproof paper

High Quality

Competitive Price

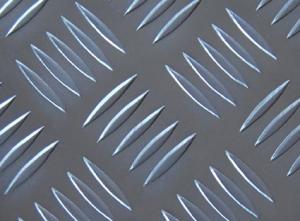

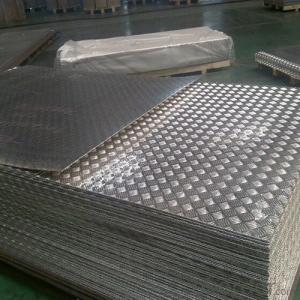

3. One Bar Diamond Aluminum Checker Plate Images:

4. One Bar Diamond Aluminum Checker Plate Specification:

Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006 .etc |

Thickness | 0.2-200mm aluminium 5050 H38 |

Width | 1250mm 1000mm or as your requirements |

Length | 3000mm 5800mm or as your requirements |

MOQ | 5 Ton |

Package | Standard export package, by wooden box or as require |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are there any limitations to the coil weight of aluminum coils?

- Yes, there are limitations to the coil weight of aluminum coils. The weight of aluminum coils is typically limited by factors such as the capacity of the equipment used for transportation or processing, the strength and stability of the packaging materials, and the safety regulations imposed by the industry. Exceeding these limitations can lead to difficulties in handling, increased risk of damage or accidents, and may impact the overall efficiency of the manufacturing or distribution process.

- Q: Can aluminum coils be used in refrigeration systems?

- Indeed, refrigeration systems can utilize aluminum coils. The rationale behind selecting aluminum as the preferred material for coil construction in refrigeration systems stems from its remarkable heat transfer capabilities and resistance to corrosion. Not only are aluminum coils lightweight and long-lasting, but they also excel in efficiently transferring heat, rendering them appropriate for a wide range of refrigeration applications, including air conditioning units, refrigerators, and freezers. Moreover, aluminum coils offer the advantage of being easier to mold and install in comparison to alternative materials, thus solidifying their position as the top choice among manufacturers.

- Q: How are aluminum coils cut and shaped?

- Aluminum coils are cut and shaped using various methods and tools, depending on the desired shape and size. The most commonly used techniques include slitting, shearing, and laser cutting. Slitting is the process of cutting a wide coil into narrower strips. It involves feeding the coil through a set of circular blades that make precise cuts along the length of the coil. This method is commonly used to produce thin strips of aluminum that are then further processed or used in various applications. Shearing is another common method used to cut aluminum coils. It involves using a machine with a moving blade to cut through the coil. The blade applies pressure to the coil, resulting in a clean and straight cut. Shearing is often used for cutting thicker aluminum coils and is suitable for producing straight cuts without any deformation. Laser cutting is a more advanced technique used to cut and shape aluminum coils. It involves using a high-powered laser beam to melt or vaporize the metal along a predetermined path. This method offers high precision and allows for complex shapes and designs to be cut into the aluminum. Laser cutting is commonly used in industries where intricate and detailed cuts are required. After the cutting process, the aluminum coils can be further shaped using various methods such as bending, rolling, stamping, or forming. These techniques allow the aluminum to be shaped into different geometries and forms according to the specific requirements of the desired application. Overall, the cutting and shaping of aluminum coils involve a range of techniques and tools, each suited for different requirements. The chosen method depends on factors such as the thickness of the coil, the desired shape, and the precision needed for the final product.

- Q: What are the typical lead times for ordering aluminum coils?

- The typical lead times for ordering aluminum coils can vary depending on various factors such as the supplier, quantity, customization requirements, and current market conditions. However, on average, lead times can range from a few weeks to a couple of months. It is advisable to contact the specific supplier for accurate information regarding their lead times.

- Q: How to calculate the length of aluminum sheet with the thickness known?

- Thickness*width*length=weight/density, length=weight/(density*thickness*width). Ps: Keep unit the same.

- Q: Are aluminum coils suitable for food and beverage packaging?

- Yes, aluminum coils are suitable for food and beverage packaging. Aluminum is a versatile material that offers various advantages for packaging applications. It is lightweight, making it easy to transport and handle. Aluminum is also highly resistant to corrosion, which ensures that the packaging remains intact and protects the contents from external factors. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer, which is beneficial for food and beverage products that require temperature control. It is also impermeable to light, moisture, and oxygen, providing an excellent barrier to maintain the quality and freshness of the packaged items. Furthermore, aluminum is recyclable and can be reused, making it an environmentally friendly choice for packaging. Overall, aluminum coils are a reliable and suitable option for food and beverage packaging due to their durability, protective properties, and sustainability.

- Q: What are the common surface treatments for aluminum coils in the marine industry?

- The common surface treatments for aluminum coils in the marine industry include anodizing, painting, and powder coating.

- Q: Can aluminum coils be used in signage applications?

- Yes, aluminum coils can be used in signage applications. Aluminum is a popular material for signage due to its durability, corrosion resistance, and lightweight nature. It can be easily formed into various shapes and sizes, making it suitable for different types of signage such as outdoor signs, billboards, trade show displays, and more. Additionally, aluminum coils offer excellent weather resistance, ensuring that the signage remains intact and vibrant even in harsh environmental conditions. The versatility and longevity of aluminum make it a preferred choice for signage applications in various industries.

- Q: And if the deodorant companies know that aluminum causes cancer, why do they keep putting it in their products?

- Aluminium-based complexes react with the electrolytes in the sweat to form a gel plug in the duct of the sweat gland. The plugs prevent the gland from excreting liquid and are removed over time by the natural sloughing of the skin. The metal salts work in another way to prevent sweat from reaching the surface of the skin: the aluminum salts interact with the keratin fibrils in the sweat ducts and form a physical plug that prevents sweat from reaching the skin’s surface. Aluminum salts also have a slight astringent effect on the pores; causing them to contract, further preventing sweat from reaching the surface of the skin.The blockage of a large number of sweat glands reduces the amount of sweat produced in the underarms,

- Q: What are the potential fire hazards associated with aluminum coils?

- The potential fire hazards associated with aluminum coils include overheating, electrical failures, and the risk of flammable materials coming into contact with the coils.

Send your message to us

5005 Aluminum Coil - One Bar Diamond Aluminum Checker Plate with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords