1/2 Inch Aluminum Plate

1/2 Inch Aluminum Plate Related Searches

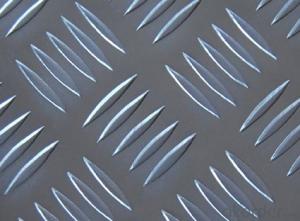

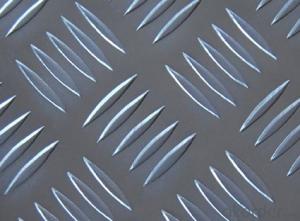

1/2 Inch Thick Aluminum Plate 1/2 Aluminum Plate Aluminum 1/2 Plate 1/2 Thick Aluminum Plate Aluminum Plate 1/2 Inch Thick 1/2 In Aluminum Plate Aluminum Plate 1/2 Thick Half Inch Aluminum Plate 1/2 Aluminum Diamond Plate 1/4 Inch Aluminum Plate 1 2 Inch Aluminum Plate 1/2 Inch Aluminum Plate Near Me 1 Inch Aluminum Plate 1/8 Inch Aluminum Plate 1/4 Inch Thick Aluminum Plate 2 Inch Aluminum Plate 5/16 Aluminum Plate 1/4 In Aluminum Plate 1/4 Aluminum Plate Aluminum Plate 1/4 Inch Thick 1/4in Aluminum Plate 1/8 In Aluminum Plate 1/4 Thick Aluminum Plate 1/2 Aluminum Plate Weight 1/16 Aluminum Plate 1/4 Plate Aluminum 5/8 Aluminum Plate 1/8 Inch Thick Aluminum Plate Weight Of 1/2 Aluminum Plate 1 2 Aluminum Plate1/2 Inch Aluminum Plate Supplier & Manufacturer from China

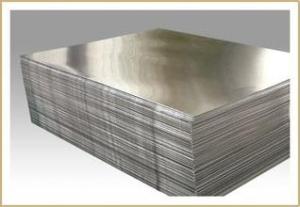

1/2 Inch Aluminum Plate is a type of metal sheet material that is widely recognized for its durability, strength, and corrosion resistance. It is made from high-quality aluminum and is available in various dimensions and thicknesses to cater to the diverse needs of different industries. This product is known for its versatility and is often used in construction, automotive, aerospace, and other manufacturing sectors.The 1/2 Inch Aluminum Plate is an ideal choice for applications where lightweight, strong, and resistant materials are required. It is commonly used in the fabrication of structural components, machinery parts, and various industrial equipment. Additionally, this product is favored for its excellent thermal and electrical conductivity, making it suitable for heat exchangers, electrical components, and other specialized applications. Its non-magnetic properties also make it a popular choice in environments where magnetic interference is a concern.

Okorder.com is a leading wholesale supplier of 1/2 Inch Aluminum Plate, boasting a vast inventory that caters to the needs of various industries. We pride ourselves on offering high-quality products at competitive prices, ensuring that our customers receive the best value for their investment. Our commitment to customer satisfaction and our extensive experience in the industry make Okorder.com the go-to source for 1/2 Inch Aluminum Plate and other metal sheet materials.

Hot Products