1100-H14 Aluminum Sheets 1/16 Thick and Aluminum Slabs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

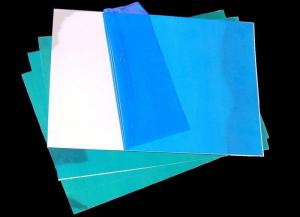

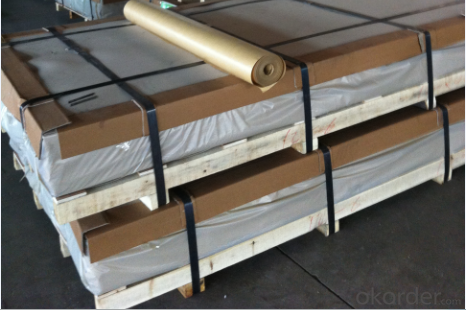

3. Image

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

- Q: Everyone said that the pre roll coated aluminum plate, what is pre roll coating?

- Beforehand, beforehand, mean,Roll coating is a paint coating process, relative to spraying, such as powder, wall coating, coating or roller coatingThe coating is applied to the surface of the aluminum sheet by a roller or steel roller. Roll coating

- Q: Are there any health risks associated with using aluminum sheets?

- There is ongoing debate and research regarding the potential health risks associated with using aluminum sheets. While aluminum is a common material used in various industries and products, it is important to consider certain factors. Exposure to high levels of aluminum, such as through inhalation or ingestion, has been linked to health issues. Studies suggest that aluminum exposure may be associated with neurological disorders, such as Alzheimer's disease or Parkinson's disease, as well as respiratory problems and bone disorders. However, it is important to note that these studies have not yet established a definitive causal relationship between aluminum and these health conditions. The primary concern with aluminum is its potential to leach into food or beverages when it comes into contact with acidic or salty substances. This leaching can occur during food preparation or storage, especially if using aluminum cookware or foil. Consuming high levels of aluminum through food or drink may pose health risks, particularly for individuals with kidney disease or those who have a higher susceptibility to aluminum toxicity. To mitigate potential health risks, it is recommended to avoid using aluminum cookware or foil when cooking or storing acidic or salty foods. Instead, consider using alternatives such as stainless steel, glass, or silicone. In conclusion, while there are concerns about the potential health risks associated with using aluminum sheets, more research is needed to establish a clear cause-and-effect relationship. It is prudent to minimize exposure to aluminum, especially through food and beverages, by adopting preventive measures and using alternative materials when appropriate. Consulting with health professionals and staying updated on the latest research can help individuals make informed decisions about using aluminum sheets and other aluminum products.

- Q: Are the aluminum sheets suitable for manufacturing architectural wall panels?

- Yes, aluminum sheets are suitable for manufacturing architectural wall panels. Aluminum is a versatile and popular material in the construction industry due to its numerous benefits. Firstly, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for architectural wall panels, as it reduces the overall weight of the structure, simplifies transportation, and allows for greater flexibility in design. Additionally, aluminum offers exceptional durability and resistance to corrosion. This is crucial for wall panels, as they are exposed to various environmental elements such as rain, UV rays, and temperature changes. Aluminum's natural oxide layer provides a protective barrier, ensuring that the panels remain intact and maintain their appearance over time. Aluminum also provides excellent thermal and acoustic insulation properties. Architectural wall panels made from aluminum can help regulate the internal temperature of buildings, leading to energy savings and improved comfort for occupants. Moreover, aluminum panels help reduce noise transmission, contributing to a quieter indoor environment. Furthermore, aluminum is highly customizable in terms of shape, size, color, and finish. This allows architects and designers to create unique and visually appealing wall panel systems that complement the overall aesthetics of a building. The versatility of aluminum sheets also facilitates the integration of other materials, such as glass or stone, for added design possibilities. Lastly, aluminum is a sustainable material. It is 100% recyclable, and the energy required for recycling aluminum is significantly lower compared to the production of primary aluminum. Choosing aluminum sheets for architectural wall panels aligns with environmentally friendly practices and contributes to the reduction of carbon emissions. Overall, the characteristics of aluminum, including its lightweight nature, durability, resistance to corrosion, thermal and acoustic insulation properties, design flexibility, and sustainability, make it highly suitable for manufacturing architectural wall panels.

- Q: This question asks about the various color options available for aluminum sheets.

- <p>Aluminum sheets are available in a wide range of colors to suit various applications and aesthetic preferences. Common colors include silver (anodized), white, black, and clear (natural). Beyond these, there are also options for colors like red, blue, green, and yellow. Some manufacturers offer custom color matching services for specific projects. Additionally, aluminum sheets can be coated with various finishes such as matte, gloss, or textured, further expanding the color and appearance options. It's important to check with specific suppliers for their available color range as it can vary.</p>

- Q: Can aluminum sheets be recycled indefinitely?

- Yes, aluminum sheets can be recycled indefinitely.

- Q: Are 101 aluminum sheets suitable for chemical processing environments?

- Chemical processing environments can utilize 101 aluminum sheets effectively. These sheets are made from a commercially pure aluminum alloy known as 101 aluminum, which boasts commendable resistance to corrosion and exceptional weldability. They find extensive application in settings demanding high corrosion resistance, such as chemical processing plants. Moreover, the protective measures of applying a coating or undergoing an anodizing process serve to augment their chemical resistance. In summary, 101 aluminum sheets are an ideal option for chemical processing environments, offering both corrosion resistance and durability when exposed to diverse chemicals.

- Q: How does the alloy composition affect the mechanical properties of aluminum sheet?

- The alloy composition of aluminum sheet plays a significant role in determining its mechanical properties. The inclusion of different elements in the alloy can influence its strength, hardness, ductility, and other characteristics. For instance, adding small amounts of copper or manganese can enhance the strength of aluminum, while magnesium can improve its corrosion resistance. Additionally, the size and distribution of alloying elements within the sheet can also impact its mechanical properties. Therefore, careful selection of alloy composition is crucial to achieve the desired mechanical performance of aluminum sheet.

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- If you are using tinfoil it is because it is coated with aluminum oxide which has a melting point of 2,000 degrees celcius.

- Q: This question asks for a list of various types of fasteners that can be used to secure aluminum windows to their frames.

- <p>There are several types of fasteners used for attaching aluminum windows to frames, including: 1. Screws: Commonly used for their secure hold and ease of installation. 2. Nails: Quick to use but may not provide the same level of security as screws. 3. Adhesives: Can be used for a more permanent bond, especially in certain applications. 4. Clips and brackets: Used for a more visible, decorative attachment. 5. Rivets: Provide a strong, permanent connection but are not easily removable. 6. Dowels and pins: Used for a more traditional or decorative join. 7. Structural glazing systems: Employ silicone or other sealants to bond the window to the frame. Each type of fastener has its own advantages and is chosen based on the specific requirements of the project, such as load-bearing needs, aesthetic considerations, and the desired level of permanence.</p>

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a non-toxic and non-reactive metal that does not leach harmful substances into food. It is widely used in the food industry for packaging, cooking utensils, and food storage containers. Additionally, aluminum exhibits excellent heat conductivity and can be easily cleaned, making it a popular choice for food-related applications.

Send your message to us

1100-H14 Aluminum Sheets 1/16 Thick and Aluminum Slabs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords