Aluminum Siding Sheets - 1100-H24 Aluminium Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet ,The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.we have a good reputationin the field of aluminium material, besides, we are one global 500 enterprise, so you can really feel free for our production quality, if you are interested in any of our products, feel free to show us your detailed inquiries later, we give you best price, etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

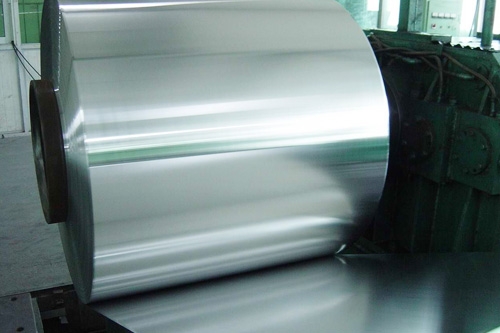

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1100mm*2200mm,1200mm*2400mm,1220mm*2440mm,1500mm*6000mm,

1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the width range?

---It is from 1000mm to 2500mm, etc.

where is your client from?

----normally they are from UAE, ARAB, SINGAPORE, INDONESIA, ETC.

How many tons did they order in one year?

---normally it is around 9000 tons totally.

what is your MOQ now?

---normally it is around 5 tons/eah size.

how often did client place one order yet?

---it is around 1 month, etc.

what is your mainly products?

---Normally they are aluminum sheet, aluminum coil, chekcered sheet, mirror finish sheet, etc.

On the material terms: the cost price of aluminum is five times more than the cost price of iron, it is to count the cost of recycling, a price of aluminum is a hair, a tin price is 2 points, chose the high cost of embossing aluminum evaporator because the aluminum evaporative cooling effect is best, ordinary refrigerator uses wire tube evaporator in order to save costs, cut corners!

Embossed aluminum embossed aluminum plate and can be referred to as: aluminum plate on the basis of belonging through the rolling process in a variety of patterns formed on the surface of aluminum products, is widely used, and mainly used in packaging, construction, walls, and so on.

Aluminum refers to aluminum or aluminum alloy material processed into (cut or sawn) obtained by pressure rectangular cross section, material thickness uniform rectangular international customary to more than 0.2mm thickness, 500mm or less, 200mm width above, aluminum length 16m or less called aluminum sheet aluminum sheet, 0.2mm or less as aluminum foil, a width of less than 200mm row material or strip (of course with the progress of large equipment, the widest 600mm can be achieved exclusive material will be more).

- Q:What are the limitations of using aluminum sheet?

- There are several limitations to using aluminum sheet. Firstly, it has a lower strength-to-weight ratio compared to other materials like steel. This means that aluminum sheets may not be as strong and durable in certain applications. Additionally, aluminum is prone to corrosion, especially in harsh environments, so proper protective coatings or treatments are necessary. Aluminum sheets also have limited formability compared to materials like steel, which can impact their use in certain complex shapes or designs. Lastly, aluminum sheets can be more expensive than other materials, which may affect their affordability in certain projects.

- Q:What are the different methods of forming aluminum sheet?

- There are several methods of forming aluminum sheet, including rolling, extrusion, stamping, and spinning.

- Q:Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum is lightweight, durable, and has excellent corrosion resistance, making it suitable for outdoor and industrial applications where glass may be prone to breakage or damage. Additionally, aluminum sheets can provide better insulation and soundproofing properties compared to glass. However, it is important to consider specific requirements and limitations of each application before choosing aluminum sheets as an alternative to glass.

- Q:Are 101 aluminum sheets readily available in the market?

- Indeed, the market offers a wide range of readily available 101 aluminum sheets. Owing to their exceptional resistance to corrosion, impressive strength, and lightweight nature, these sheets find frequent use across various industries and applications. They can be conveniently obtained from metal supply stores, online marketplaces, and specialized aluminum suppliers. Moreover, customers have the liberty to select from a variety of sizes, thicknesses, and finishes for 101 aluminum sheets, ensuring the perfect match for their specific needs.

- Q:How does the surface finish of aluminum sheet affect its cleaning requirements?

- The surface finish of aluminum sheet can greatly impact its cleaning requirements. A smooth and polished surface finish tends to be more resistant to dirt, stains, and corrosion, making it easier to clean. On the other hand, a textured or rough surface finish can trap dirt and debris, requiring more effort and specialized cleaning techniques to remove them effectively. Additionally, specific surface finishes may be more prone to scratching or damage during cleaning, necessitating a more gentle approach. Overall, the surface finish of aluminum sheet directly influences the cleaning method and effort needed to maintain its appearance and functionality.

- Q:Are aluminum sheets suitable for marine applications?

- Yes, aluminum sheets are suitable for marine applications. Aluminum is lightweight, corrosion-resistant, and has excellent strength-to-weight ratio, making it ideal for various marine applications such as boat hulls, decks, and structural components. Additionally, aluminum's low maintenance requirements and durability in harsh marine environments further contribute to its suitability for such applications.

- Q:Can 101 aluminum sheets be polished to a mirror-like finish?

- A mirror-like finish can be achieved on 101 aluminum sheets. Aluminum, being a lightweight and highly malleable metal, can be easily polished to obtain a reflective surface. Nevertheless, achieving a mirror-like finish on aluminum requires several steps and the use of appropriate polishing techniques and materials. To achieve a mirror-like finish on aluminum sheets, it is customary to begin by thoroughly cleaning the surface to eliminate any dirt, debris, or oxidation. Following that, sanding the surface with progressively finer sandpaper grits is necessary to eliminate imperfections or scratches. This step is vital in order to create a smooth and uniform surface that can be polished to a high level of shine. Once the sanding is completed, the polishing stage comes into play. There are various methods and materials available for polishing aluminum, such as abrasive compounds, buffing wheels, and polishing pads. These tools are utilized to exert pressure and friction on the aluminum surface, effectively removing any remaining scratches or imperfections and resulting in a smooth, reflective finish. Ultimately, to achieve a genuine mirror-like finish, the process of buffing or burnishing is often employed. This entails applying a polishing compound to the aluminum surface using a soft cloth or a specialized buffing wheel. The compound further refines the surface and enhances its reflective properties, ultimately leading to a mirror-like finish. It is important to note that achieving a mirror-like finish on aluminum can be a time-consuming and labor-intensive process, particularly when dealing with a large quantity of sheets like 101. Additionally, the quality of the aluminum sheets themselves and the skill level of the individual performing the polishing can also impact the final outcome. Nevertheless, with the right materials, techniques, and patience, it is indeed possible to polish 101 aluminum sheets to a mirror-like finish.

- Q:Are aluminum sheets resistant to rust?

- Indeed, the resistance of aluminum sheets to rust is remarkably high. This is due to the natural formation of a protective oxide layer on the surface of aluminum when it comes into contact with air, thereby hindering further corrosion. In contrast to iron or steel that can rust in the presence of moisture and oxygen, aluminum does not necessitate any supplementary coatings or treatments to safeguard against rust formation. Consequently, aluminum sheets are widely favored across various sectors such as construction, automotive, and marine industries, where the prevention of rust is imperative.

- Q:Can aluminum sheets be used for reflective surfaces?

- Indeed, reflective surfaces can be crafted using aluminum sheets. Renowned for its exceptional reflectivity, aluminum proves to be an ideal material for producing such surfaces. With its sleek and impeccably polished texture, aluminum sheets efficiently bounce back light, heat, and various types of radiation. This remarkable attribute renders them suitable for an extensive array of purposes, encompassing solar panels, mirrors, lamp reflectors, and reflective insulation. Utilizing aluminum sheets as reflective surfaces offers numerous advantages, including their enduring nature, lightweight composition, and resistance to corrosion.

- Q:How do aluminum sheets perform in terms of fatigue resistance?

- Aluminum sheets generally exhibit good fatigue resistance due to their high strength-to-weight ratio and ductility. This means that they can withstand repeated loading cycles without experiencing significant degradation or failure. However, the fatigue resistance of aluminum sheets can vary depending on factors such as the alloy composition, heat treatment, and surface condition. Therefore, it is important to consider these factors when assessing the performance of aluminum sheets in terms of fatigue resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Siding Sheets - 1100-H24 Aluminium Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords