Atp 5 Aluminum Tooling Plate

Atp 5 Aluminum Tooling Plate Related Searches

Atp-5 Aluminum Tooling Plate Atp 5 Aluminum Plate Atp 5 Cast Aluminum Plate Atp-5 Cast Aluminum Plate Aluminum Tooling Plate Aluminum Tool Plate Aluminum 5th Wheel Plate Cast Aluminum Tooling Plate Aluminum Fifth Wheel Plate 5 Aluminum Plate Mic 6 Aluminum Tooling Plate 5mm Thick Aluminum Plate Aluminum Tooling Plate Alloy T5mm Aluminum Plate 5mm Aluminum Plate Aluminum Plate 5mm 5 Bar Aluminum Plate 5 16 Aluminum Plate 5 Bar Aluminum Tread Plate Alca 5 Aluminum Plate Tapping Aluminum Plate K100 Aluminum Tooling Plate 5 8 Aluminum Plate C250 Aluminum Cast Tooling Plate Aluminum Tooling Plate Mic-6 5/16 Aluminum Plate Aluminum T Plate 5/8 Aluminum Plate Aluminum Tooling Plate Suppliers 5005 Aluminum PlateAtp 5 Aluminum Tooling Plate Supplier & Manufacturer from China

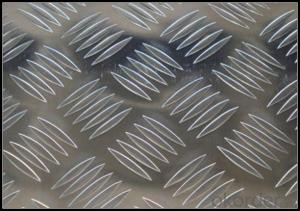

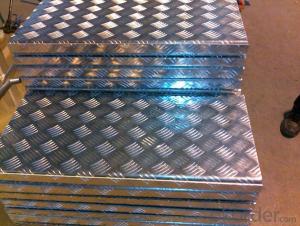

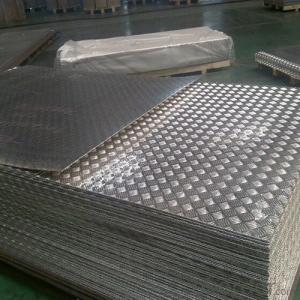

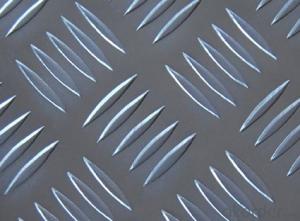

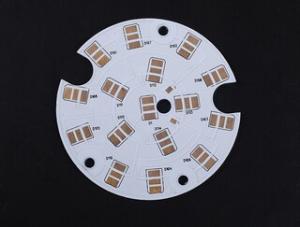

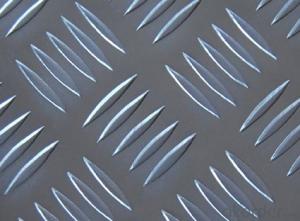

Atp 5 Aluminum Tooling Plate is a high-quality material used in various industries for its strength, durability, and excellent thermal conductivity. This product is widely recognized for its precision and consistency, making it an ideal choice for applications that require intricate detailing and high-performance standards. The Atp 5 Aluminum Tooling Plate is particularly favored in the manufacturing of molds, dies, and other precision components where reliability and accuracy are paramount.The Atp 5 Aluminum Tooling Plate finds its application in a multitude of scenarios, including automotive, aerospace, and electronics industries. Its use extends to the creation of prototypes, production tools, and jigs and fixtures, where its superior strength-to-weight ratio and heat dissipation properties are highly beneficial. This product is also favored for its ability to withstand high temperatures and resist corrosion, making it suitable for applications that demand long-term durability and minimal maintenance.

Okorder.com is a reputable wholesale supplier of Atp 5 Aluminum Tooling Plate, boasting a vast inventory that caters to the diverse needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Atp 5 Aluminum Tooling Plate is readily available for businesses looking to enhance their production capabilities and maintain a competitive edge in the market.

Hot Products