Aluminum Plate Sheets - 5 Bars Plate/Tearplate of Good Quality in Hot Sale!

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

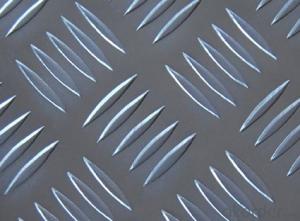

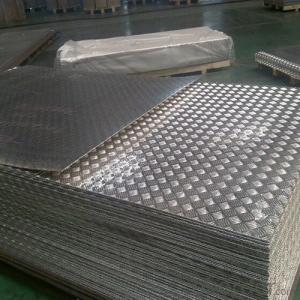

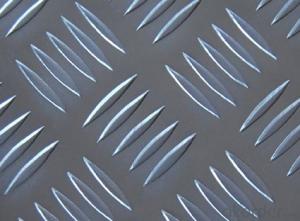

1.Structure of Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale:

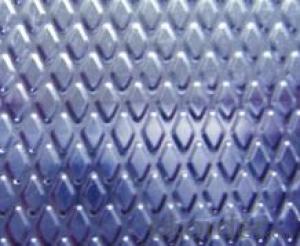

Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Saleis widely used for decorative purposes in construction, packing and appliance. Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Saleis also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale:

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm-1500mm

4. Production of Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: This question asks for methods to prevent aluminum sheets from warping or curling during processing or storage.

- <p>To prevent aluminum sheets from warping or curling, ensure proper storage by keeping them flat and avoiding stacking them under heavy loads. Maintain a controlled environment with consistent temperature and humidity to prevent expansion and contraction. When cutting, use sharp tools to minimize heat generation and stress. Apply a stress-relieving process after fabrication to reduce internal stresses. Use appropriate jigs and fixtures during fabrication to maintain flatness. Finally, consider the thickness and alloy of the aluminum sheet, as some are more prone to warping than others.</p>

- Q: Is it possible to use aluminum sheets for constructing a sustainable building?

- <p>Yes, aluminum sheets can be used to create a sustainable building due to their recyclability, low thermal conductivity, and durability. Aluminum is a lightweight material that can reduce the energy consumption in transportation and construction. It also has a high recycled content ratio and can be easily recycled, which reduces waste. Additionally, aluminum's low thermal conductivity can contribute to energy efficiency in buildings by reducing heat transfer, thus lowering energy costs for heating and cooling. However, it's important to consider the entire life cycle of the material and ensure that the manufacturing and disposal processes align with sustainable practices.</p>

- Q: Can aluminum sheet be used for electrical bus bars?

- Certainly, electrical bus bars can indeed utilize aluminum sheet. Aluminum is widely employed in electrical applications because of its exceptional conductivity and cost-effectiveness. Its electrical conductivity is high, comparable to copper, enabling it to effectively carry significant currents. Moreover, aluminum is lightweight and exhibits commendable resistance against corrosion, rendering it a favored option for bus bars in specific applications. Nevertheless, it is crucial to carefully evaluate the electrical system's specific requirements and standards before opting for aluminum sheet as bus bars.

- Q: Can aluminum sheets be used for balcony railings?

- Yes, aluminum sheets can be used for balcony railings. Aluminum is a lightweight and durable material that is commonly used for this purpose due to its resistance to rust and corrosion. Additionally, aluminum can be easily shaped and customized to meet specific design requirements, making it a popular choice for balcony railings.

- Q: What safety measures should be taken into account when installing aluminum sheets?

- <p>When installing aluminum sheets, it's important to follow safety precautions. Always wear appropriate personal protective equipment, including gloves and safety glasses. Ensure the work area is clear of debris and other hazards. Use the correct tools for cutting and handling aluminum sheets to prevent injuries. Be cautious of sharp edges and corners that can cause cuts. Ensure the aluminum sheets are properly secured to avoid them falling and causing harm. Follow all manufacturer guidelines for installation to ensure the stability and longevity of the aluminum sheets.</p>

- Q: Can aluminum sheets be used for HVAC systems?

- Certainly, HVAC systems can utilize aluminum sheets. Aluminum proves to be a favored material for HVAC applications owing to its numerous beneficial characteristics. Its lightweight nature facilitates effortless handling and installation. Moreover, aluminum exhibits remarkable resistance to corrosion, a vital attribute for HVAC systems subject to moisture and fluctuating temperatures. Additionally, aluminum boasts exceptional thermal conductivity, ensuring efficient heat transfer. Consequently, it becomes ideal for heat exchangers and other HVAC system components. In summary, aluminum sheets emerge as a dependable and long-lasting choice for HVAC systems.

- Q: How do you join two aluminum sheets together?

- There are several methods to join two aluminum sheets together. One common technique is using mechanical fasteners such as screws, rivets, or bolts. These fasteners can be drilled or punched through the sheets, creating a secure connection. Another method is using adhesives specifically designed for aluminum bonding. These adhesives provide a strong and durable bond between the two sheets. Welding is another popular option, where the aluminum sheets are melted and fused together using heat. This method requires specialized equipment and expertise. Lastly, a technique called clinching can be used, which involves applying pressure to deform the aluminum sheets and interlock them together. Each method has its own advantages and considerations, depending on the specific application and desired outcome.

- Q: What are the different methods of surface etching aluminum sheets?

- Aluminum sheets can be surface etched using various methods, each with its own benefits and specific uses. Some commonly employed techniques are chemical etching, laser etching, and mechanical etching. Chemical etching entails the selective removal of the aluminum sheet's surface using a chemical solution. This method allows for precise and intricate designs or patterns. It finds application in decorative purposes like creating logos or artwork on aluminum signage or nameplates. Additionally, chemical etching aids in functional enhancements, such as improving paint or coating adhesion. Contrarily, laser etching involves employing a high-powered laser to eliminate material from the aluminum sheet's surface. This technique offers exceptional precision, enabling the creation of fine details. It is frequently utilized for marking or engraving aluminum sheets, such as for serial numbers, barcodes, or product identification. Laser etching is also a non-contact process, ensuring no physical harm to the sheet. Mechanical etching, also known as abrasive blasting, employs an abrasive material to physically eliminate the aluminum sheet's surface. This technique is typically utilized for larger-scale applications, like achieving a textured or matte finish on aluminum panels or sheets. Mechanical etching can also remove surface imperfections or contaminants, preparing the aluminum sheet for subsequent processing or finishing. In conclusion, surface etching of aluminum sheets can be accomplished through chemical etching, laser etching, or mechanical etching. Each method provides distinct advantages and serves specific purposes, ranging from decorative designs to functional markings or surface treatments.

- Q: I have to repair a cracked aluminum engine block. What alumunum epoxy should I use?

- cracked where? i could suggest the wonder rods, such as dura-fix. i've used them on some aluminum repairs in the past. when the thickness of the materials is uniform, its a good easy to use product. when the thickness changes, its useless. i wouldnt think of using it on a motor repair though. melting temp is a bit low, much closer to combustion temps then alum's melting temp. the truly best way to fix anything alum is with a TIG welder in the hands of somebody who knows how to use it. but, any good welder will probably look at you like you are nuts when you bring a motor in to be welded. depending on exactly what you have, the entire powerblock, which is the motor part, might be avaible for purchase to replace your old one with. it may be priced at under a $1,000. you would end up with a brand new motor. for outboards, when teh drive is in good condition, this can be a great way to get a brand new outboard performance at a far cheaper price.

- Q: How do aluminum sheets handle extreme temperatures?

- Aluminum sheets are known for their exceptional ability to handle extreme temperatures. Due to their high thermal conductivity, aluminum sheets can effectively dissipate heat, making them suitable for applications that involve high temperatures. Aluminum has a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), which means it can withstand a wide range of extreme temperatures without losing its structural integrity. When exposed to extreme heat, aluminum sheets do not deform or warp easily, making them ideal for use in environments with high temperatures such as industrial furnaces, automotive engines, and aerospace applications. Additionally, aluminum has a low coefficient of thermal expansion, meaning it expands and contracts minimally when subjected to temperature variations, reducing the risk of cracking or structural damage. On the other hand, aluminum also performs well in extremely cold temperatures. It remains durable and retains its strength even in freezing conditions. This makes aluminum sheets suitable for use in cryogenic applications, such as in the construction of liquid natural gas tanks or aerospace components that operate in low-temperature environments. In summary, aluminum sheets excel in handling extreme temperatures due to their high thermal conductivity, low coefficient of thermal expansion, and excellent structural integrity. Whether subjected to intense heat or extreme cold, aluminum sheets remain stable and reliable, making them a preferred choice in various industries.

Send your message to us

Aluminum Plate Sheets - 5 Bars Plate/Tearplate of Good Quality in Hot Sale!

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords