Home Depot 0.020 Plain Aluminum Sheets - 1000 3000 5000 Series Cast Rolled Hot Rolled Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product details

| Product Name | Mill finish aluminum sheet |

| Alloy | 1050,1060,1100,3003,3004,3005,3105,5005,5052,5754,5083 |

| Temper | O, H12,H14,H16,H18,H22, H24,H32,H112 |

| Thickness | 0.18mm-350mm |

| Width | 300mm-1930mm |

| Inner packing | PVC film(30 μm, 60 μm, 80 μm) or Paper inter leaved |

| Outside packing | International wood pallet(fumigated) with steel strip |

b.Mechanical property

| Alloy grade | Bend | Tensile Strength( Mpa) | Elongation (%) |

| 1100 H14 | 1/2 closed | 132 | 13 |

c.Chemical composition

| Alloy grade | Si (%) | Fe(%) | Cu(%) | Mg (%) | Cr (%) | Mn (%) | Zn (%) | Ti (%) | Al (%) | Standard |

| 1100 H14 | 0.102 | 0.501 | 0.069 | <0.03< span=""> | <0.005< span=""> | <0.03< span=""> | <0.03< span=""> | 0.0191 | else | GB/T3880-2006 |

l Packaging & Delivery

Packaging detail: wooden cases that are suitable for long distance exporting

Delivery detail: 25-30 days after receiving L/C or payment in advance

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

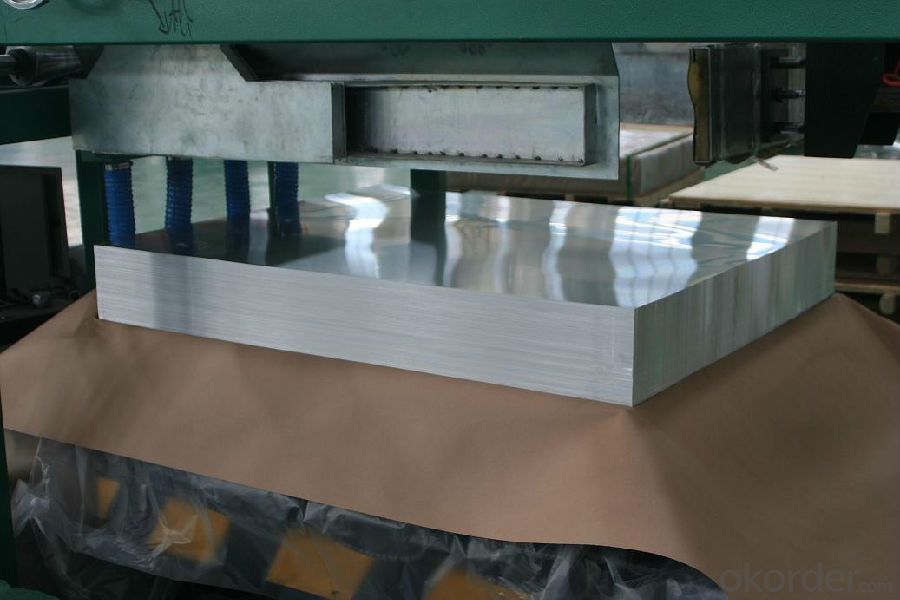

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Name: Amanda Qian

Email: amandaqian@okorder.com

- Q: need help choosing an aluminum welder at a descent price also

- i think, welding,,, tig is right machine for aluminum, thank you.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum is lightweight, durable, and has excellent corrosion resistance, making it suitable for outdoor and industrial applications where glass may be prone to breakage or damage. Additionally, aluminum sheets can provide better insulation and soundproofing properties compared to glass. However, it is important to consider specific requirements and limitations of each application before choosing aluminum sheets as an alternative to glass.

- Q: A dry aluminium foil paper can be bring out from oven with no burn on finger but if foil has some moisture it will result in burn why?

- It isn't the foil that is burning you--it's the water. Aluminum foil is a good heat conductor. This means that when you expose the foil to the air, it will cool off very rapidly (rapidly reaching room temperature). Water is NOT a good heat conductor, in fact, it likes to hold onto it's heat. So while the dry foil may come to room temperature (or just warm to the touch) in a few seconds, the water will stay hot for much longer (depending on how much water there is obviously). It's really the same as trying to grab a baked potato wrapped in foil off of the grill. If you grab the potato you will burn your hand (because the potato is holding A LOT of heat), but if you carefully peel away the foil, you can touch and take the foil off with your bare hand. I should say that the mass of the foil also plays a role here. The foil is not very massive and thus does not hold a lot of raw energy to begin with (also because it's a good heat conductor it dissipates quickly). Bu if you put an aluminum can (or a brick of aluminum) in the oven, I guarantee that it would stay hotter for much longer than just a piece of aluminum foil.

- Q: Can aluminum sheets be used for water tanks?

- Yes, aluminum sheets can be used for water tanks. Aluminum is a corrosion-resistant material and is commonly used in the construction of water tanks due to its durability and ability to withstand harsh weather conditions.

- Q: Are aluminum sheets suitable for aerospace wing structures?

- Yes, aluminum sheets are often used in aerospace wing structures due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance.

- Q: What are the standards and certifications available for aluminum sheets?

- There are several standards and certifications available for aluminum sheets, including the American Society for Testing and Materials (ASTM) standards, the Aluminum Association standards, and the ISO 9001 certification. These standards and certifications ensure the quality, durability, and performance of aluminum sheets, and help customers make informed decisions while selecting the appropriate product for their specific applications.

- Q: Can aluminum sheets be used for decorative purposes?

- Yes, aluminum sheets can definitely be used for decorative purposes. Aluminum is a versatile and lightweight material that can be easily manipulated into different shapes, sizes, and designs. It can be painted, coated, or anodized in various colors to match any aesthetic preference. Aluminum sheets can be used as decorative panels, signage, wall cladding, ceiling tiles, and even in furniture design. Additionally, aluminum is resistant to corrosion, making it a durable option for both indoor and outdoor applications. Its reflective surface can also create a sleek and modern look in any space. Overall, aluminum sheets offer a wide range of possibilities for adding a decorative touch to any project.

- Q: Is it possible to substitute aluminum sheets for wood siding in construction?

- <p>Yes, you can use aluminum sheets to replace wood siding. Aluminum siding is a popular alternative to wood for several reasons. It is lightweight, durable, and resistant to rot, insects, and moisture. It also requires less maintenance than wood and can be painted to match various aesthetic preferences. However, it's important to consider factors such as insulation properties, cost, and the look you want to achieve, as aluminum may not perfectly mimic the appearance of wood. Always consult with a professional to ensure proper installation and compatibility with your home's architecture.</p>

- Q: I am trying to find a BRUSH ON type glue to adhere aluminium foil to a plastic model. scotch super 77 works great but dries way to fast and blows small pieces all over. white glue just dont work and superglue eats the plastic. I could use some help

- Strange... okorder /

- Q: Can aluminum sheets be anodized for added durability?

- Yes, aluminum sheets can be anodized for added durability. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum. This layer not only enhances the appearance of the material but also increases its resistance to corrosion, wear, and scratches. Anodizing provides a hard, durable, and long-lasting finish, making it an ideal choice for various applications where durability is crucial, such as in construction, automotive, aerospace, and electronics industries. Additionally, anodized aluminum sheets can be dyed in various colors, further enhancing their aesthetic appeal while maintaining their durability.

Send your message to us

Home Depot 0.020 Plain Aluminum Sheets - 1000 3000 5000 Series Cast Rolled Hot Rolled Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords