Sheet Diamond Plate Aluminum

Sheet Diamond Plate Aluminum Related Searches

Sheet Aluminum Diamond Plate Aluminum Sheet Diamond Plate Diamond Plate Sheet Aluminum Sheet Of Diamond Plate Aluminum Diamond Plate Aluminum Sheets Diamond Plate Aluminum Sheeting Sheets Of Aluminum Diamond Plate Aluminum Sheet Plate 1 4 Diamond Plate Aluminum Sheet 4x8 Sheet Diamond Plate Aluminum 1/4 Diamond Plate Aluminum Sheet 1 8 Diamond Plate Aluminum Sheet 4x8 Sheet Aluminum Diamond Plate Aluminum Sheet And Plate Diamond Embossed Aluminum Sheet Aluminum Diamond Plate 4x8 Sheet Aluminum Diamond Plate Panels Diamond Plate Aluminum Sheets 4X8 Aluminum Diamond Deck Plate Polished Aluminum Diamond Plate Aluminum Tread Plate Sheet Metal Buy Aluminum Diamond Plate Aluminum Diamond Plate Strips Welding Aluminum Diamond Plate Checker Plate Aluminum Sheets Bending Aluminum Diamond Plate Aluminum Checker Plate Sheet Black Diamond Plate Aluminum Aluminum Diamond Plate Material Aluminum Black Diamond PlateSheet Diamond Plate Aluminum Supplier & Manufacturer from China

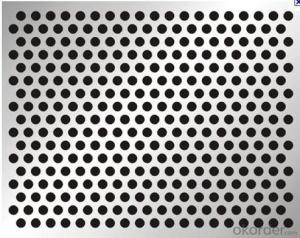

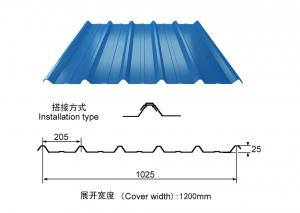

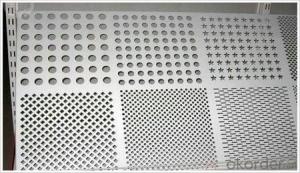

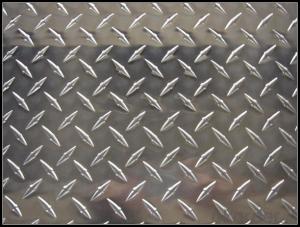

Sheet Diamond Plate Aluminum is a type of aluminum sheet material that features a raised, diamond-shaped pattern on one side, providing a slip-resistant surface. This unique design not only enhances safety but also offers a visually appealing finish. The product is widely recognized for its durability, corrosion resistance, and lightweight properties, making it an ideal choice for various industries and applications.Sheet Diamond Plate Aluminum finds its application in a multitude of scenarios, including flooring, stair treads, ramps, walkways, and platforms, where slip resistance and durability are crucial. It is also commonly used in the construction, automotive, and marine industries, as well as for manufacturing equipment and machinery that requires a non-slip surface. The product's versatility and strength make it a popular choice for both commercial and residential projects, ensuring safety and efficiency in various environments.

As a leading wholesale supplier, Okorder.com offers an extensive inventory of Sheet Diamond Plate Aluminum, catering to the needs of businesses and individuals alike. With a commitment to providing high-quality products at competitive prices, Okorder.com ensures that customers can access the Sheet Diamond Plate Aluminum they require for their projects without compromising on quality or budget.

Hot Products