Aluminum Diamond Plate Sheets Prices - Embossed Aluminum Alloy Sheets Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Embossed Sheets Aluminum Alloy for Sale Made in China Supplier

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Embossed Sheets Aluminum Alloy for Sale Made in China Supplier

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Embossed Sheets Aluminum Alloy for Sale Made in China Supplier

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

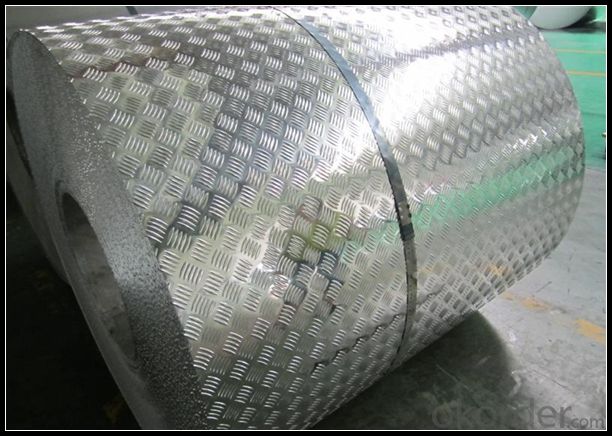

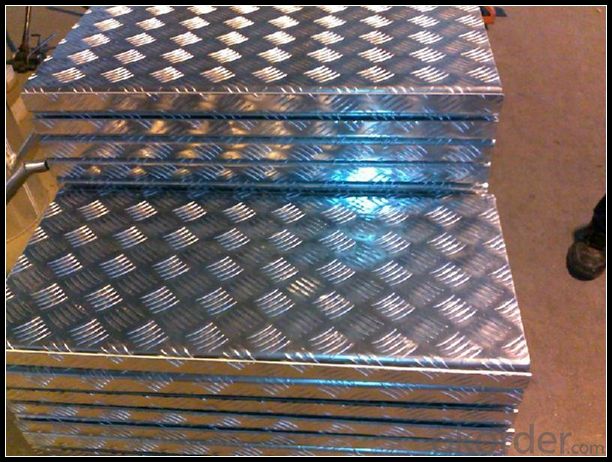

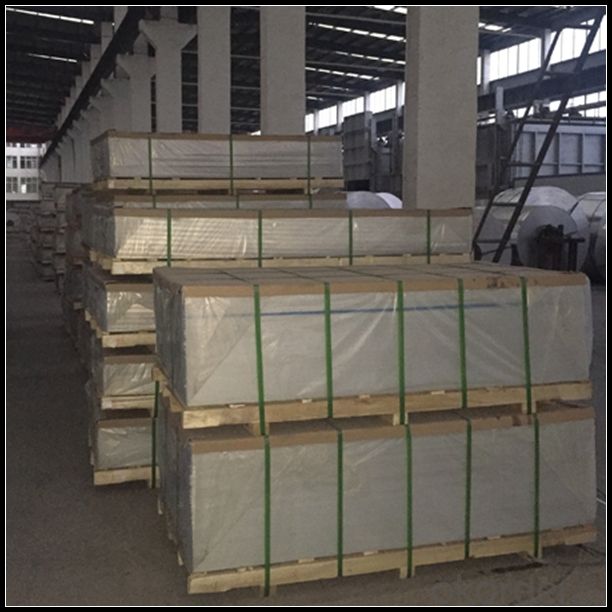

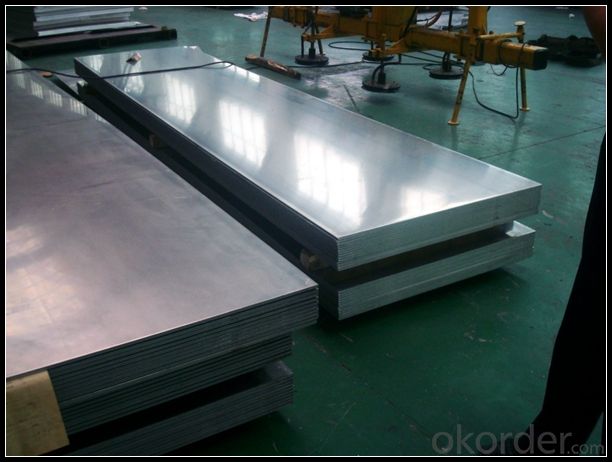

5. Image of Embossed Sheets Aluminum Alloy for Sale Made in China Supplier

6. Package and shipping of Embossed Sheets Aluminum Alloy for Sale Made in China Supplier

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is aluminium oxide sheet?

- The aluminum oxide plate is placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, and electrolysis is carried out under certain conditions and applied current. Anodized aluminum plate on the surface of the formation of alumina thin layer, its thickness is 5~20 microns, hard anodized film up to 60~200 microns.

- Q: Are aluminum sheets suitable for laser cutting?

- Yes, aluminum sheets are suitable for laser cutting. Aluminum is a commonly used material in laser cutting due to its excellent reflective properties, high thermal conductivity, and low melting point. These characteristics make it an ideal material to be cut by a laser beam. Laser cutting provides precise and clean cuts on aluminum sheets, allowing for intricate designs and complex shapes to be easily achieved. Additionally, laser cutting of aluminum sheets is a fast and efficient process, offering high productivity and cost-effectiveness.

- Q: How is an aluminum sheet manufactured?

- The process called rolling is used to manufacture an aluminum sheet. Initially, a large aluminum ingot is heated to a specific temperature in a furnace. Once the ingot reaches the desired temperature, it is transferred to a rolling mill. Within the rolling mill, the heated aluminum ingot is passed between a series of rolling stands. These stands consist of two steel rollers that apply pressure on the aluminum, steadily decreasing its thickness. As the ingot moves through each stand, the distance between the rollers is altered to achieve the desired thickness. Throughout the rolling process, the aluminum sheet is continuously cooled using water to prevent overheating. This cooling process also enhances the strength and hardness of the sheet. The specific cooling method may vary depending on the alloy and desired properties of the sheet. Once the desired thickness is achieved, the aluminum sheet undergoes further processing to improve its surface finish. This may involve techniques like annealing, where the sheet is heated and gradually cooled to relieve internal stresses and enhance workability. Finally, the aluminum sheet is cut into the desired sizes and shapes using shearing or sawing techniques. It can also undergo additional treatments such as coating, painting, or polishing, depending on its intended application. In summary, the manufacturing of an aluminum sheet involves heating the ingot, rolling it between sets of steel rollers to reduce its thickness, cooling it, and then further processing to achieve the desired surface finish and size. This process guarantees the production of top-quality aluminum sheets suitable for various industries, including construction, automotive, aerospace, and more.

- Q: Can aluminum sheets be welded?

- Yes, aluminum sheets can be welded.

- Q: What is the classification of 6061106070 aluminum plate, which respectively represent what it means to ask God for help

- 6061, 1060, 7075, these we call "aluminum plate" brand, six beginning, we usually call six Department of aluminum, the beginning of a department of aluminum is pure aluminum, there are 1050, 1060, 1100, etc., aluminum content is more than 99%. Two at the beginning of the Al Cu alloy, 2024 and 2017, less domestic, belongs to aviation aluminum, in addition to the seven lines is the two most hard.

- Q: What types of aluminum sheets are recommended for outdoor use due to their properties?

- <p>Yes, there are specific types of aluminum sheets designed for exterior applications. These include aluminum sheets with protective coatings such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a PVDF (Polyvinylidene Fluoride) coating, such as Kynar 500, are highly suitable for exterior use due to their excellent durability and resistance to UV rays, chemicals, and scratches. These coatings help maintain the aluminum's appearance and integrity over time, making them ideal for outdoor applications where exposure to the elements is a concern.</p>

- Q: What are the different methods of surface preparation for adhesive bonding of aluminum sheet?

- There are several different methods of surface preparation for adhesive bonding of aluminum sheet. These methods include mechanical abrasion, chemical etching, and surface treatments such as anodizing or conversion coating. Mechanical abrasion involves roughening the surface of the aluminum sheet using sandpaper or other abrasive materials to improve adhesion. Chemical etching involves using acid or alkaline solutions to create a textured surface on the aluminum sheet. Surface treatments such as anodizing or conversion coating involve applying a protective layer or coating to the aluminum sheet to enhance adhesion. Ultimately, the choice of surface preparation method depends on the specific requirements of the adhesive bonding process and the type of adhesive being used.

- Q: Can aluminum sheets be used for aircraft manufacturing?

- Indeed, aircraft manufacturing commonly utilizes aluminum sheets. This lightweight and corrosion-resistant material proves to be an excellent option for crafting diverse aircraft components. Its strength allows it to endure the pressures and tensions experienced during flight, while its malleability enables it to take on various forms and sizes. Moreover, aluminum sheets can be effortlessly joined together using diverse welding techniques, facilitating efficient and effective assembly of aircraft structures. Consequently, the utilization of aluminum sheets in aircraft manufacturing ensures a harmonious combination of strength, weight, and durability, rendering it a favored material in the aerospace sector.

- Q: Can aluminum sheet be used for electronic components?

- Indeed, aluminum sheet is a viable option when it comes to electronic components. This versatile material boasts numerous advantages for electronic applications. Not only is it lightweight, but it also exhibits exceptional thermal conductivity and corrosion resistance. These characteristics render it suitable for a wide range of electronic components, including heat sinks, enclosures, connectors, and printed circuit boards (PCBs). The machinability, formability, and weldability of aluminum sheets further enable efficient manufacturing processes. Moreover, aluminum proves to be a cost-effective alternative to materials like copper or steel. Nevertheless, it is crucial to acknowledge that aluminum may not be suitable for all electronic components, particularly those necessitating high electrical conductivity or magnetic shielding.

- Q: How does the formability of aluminum sheet vary with different alloys?

- Variations in chemical composition and mechanical properties result in significant differences in the formability of aluminum sheet among different alloys. To enhance specific characteristics like strength, corrosion resistance, and formability, aluminum alloys are typically combined with elements such as copper, manganese, magnesium, and zinc. Aluminum alloys like the 1xxx series (pure aluminum) and the 3xxx series (manganese alloyed) are highly formable and commonly used for deep drawing applications. These alloys can be shaped into complex forms without cracking or tearing. In contrast, alloys with higher strength properties, such as the 2xxx series (copper alloyed) and the 7xxx series (zinc alloyed), generally have reduced formability. Although these alloys are often used in structural applications where strength is crucial, they require careful handling and processing to avoid defects during forming. Alloys in the 5xxx series (magnesium alloyed) offer a good balance of formability and strength. They are widely used in industries like automotive and aerospace, as they can be easily formed into different shapes while providing sufficient strength and corrosion resistance. It's important to note that the formability of aluminum sheet is not solely determined by the alloy composition. Other factors such as sheet thickness, forming temperature, and the specific forming process employed (e.g., deep drawing, bending, stretching) also influence formability. These factors interact with alloy properties to affect the formability characteristics of aluminum sheet. Therefore, careful selection of the appropriate alloy and process parameters is essential to achieve the desired formability for specific applications.

Send your message to us

Aluminum Diamond Plate Sheets Prices - Embossed Aluminum Alloy Sheets Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords