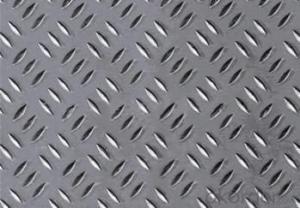

Aluminum Painted Embossed Diamond Aluminum Sheet - Diamond Embossed Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction:

Electrodes in the aluminum foil, aluminum foil wool, the curtain with aluminum belt, 3105, 1235, 1050, 1145, 1200, 8011 o, H22, H24, H26, H180.20 ~ 0.80 mm, width 800 ~ 1900

Non-slip aluminum sheet 7. All kinds of decorative pattern, five reinforcement, the pointer shape and decorative pattern, in addition, produce 3003 orange peel pattern aluminum coil.

Goods of Description:

1. Roll casting slab billet 1060105 0107 0110 0300 3310, 5, 3 A21, LF21, 5052801 1, etc.

2. Various USES aluminum plate, various USES aluminium strip, processing customized according to user requirements.

3. The cable foil, cable aluminum belt, cable coated with aluminum foil, 8011 o0. 12 ~ 0.20 mm wide, 50 ~ 1300106 0 O0.5 ~ 2.0 mm wide, 50 ~ 1300.

4. Lu: su composite work aluminum strip, 8011 o0. 16-10-1200 - mm * 0.3 mm * l.

5. Aluminium and aluminium alloy curtain wall construction, decoration, 1070, 1070, 1050, 3003, 3 a21h16, H14, H26, H181.5 ~ 4.0 mm wide, 1000 ~ 1000 long and 1000 ~ 6000.

Application:

suitable for wastewater treatment, water, power plant in other industries outside, checkered plate is used for mechanical antiskid and interior decoration, prevent slippery, wharf, diaoyutai state guesthouse, workshop, at the bottom of the car, cement floor, the door of the hotel, etc.

- Q: Can aluminum sheets be used in aerospace industries?

- Yes, aluminum sheets can be used in aerospace industries. Aluminum is commonly used in the aerospace industry due to its lightweight, high strength-to-weight ratio, and corrosion resistance properties. It is used for various applications such as aircraft structures, wings, fuselages, and skins.

- Q: Can aluminum sheets be an alternative to plastic in certain applications?

- Yes, aluminum sheets can be a viable alternative to plastic in certain applications. Aluminum is a lightweight and durable material that offers numerous advantages over plastic. It has excellent strength-to-weight ratio, making it suitable for applications that require resistance to impact or heavy loads. Additionally, aluminum is highly resistant to corrosion, which makes it ideal for outdoor or marine applications where plastic may degrade over time. Moreover, aluminum is a highly recyclable material, which aligns with the growing emphasis on sustainability and reducing waste. Unlike plastic, which can take hundreds of years to decompose, aluminum can be recycled indefinitely without losing its properties. This makes aluminum a more environmentally friendly choice for applications where plastic waste is a concern. Furthermore, aluminum sheets offer superior thermal conductivity compared to plastic, making them suitable for applications that require heat dissipation or thermal management. This makes aluminum a preferred choice for products such as heat sinks or electronic enclosures. However, it's important to note that aluminum sheets may not always be the best alternative to plastic. Plastic offers certain advantages such as being lightweight, flexible, and cost-effective, which makes it more suitable for applications that require these properties. Additionally, plastic can be molded into complex shapes, making it preferable for certain designs. In conclusion, aluminum sheets can be an effective alternative to plastic in certain applications where their strength, durability, corrosion resistance, recyclability, or thermal conductivity are advantageous. However, the choice between aluminum and plastic ultimately depends on the specific requirements and constraints of the application at hand.

- Q: What does 1060h/24 mean in aluminium alloy?

- In two the number of Arabia aluminum has no special meaning, is only used to identify the different alloys in the same group, said its second modifications.Four, H24 H said the work hardening of the state, and some do not have H but T said it is heat treatment.24 machining process control hardness and other properties, in addition to 24 and 12, 14, 16, 18, 22, 26, 34, 36 and so on, usually at the end of 4 is a semi hard state.1060O, 1060-H22, 1060-H24, 1060-H18 state is arranged from soft to hard.

- Q: This question asks for a comparison of various types of aluminum sheet materials, highlighting their unique characteristics and differences.

- <p>Aluminum sheet materials vary based on alloy composition, thickness, and surface treatment. Common types include 1000 series (99% pure aluminum), 3000 series (alloys like 3003 and 3004), 5000 series (magnesium alloys), and 6000 series (magnesium-silicon alloys). Each series has distinct properties: 1000 series is soft and ductile, 3000 series offers moderate strength and good formability, 5000 series has high strength and corrosion resistance, and 6000 series is known for its strength and excellent weldability. Thickness and temper (hardness) also affect performance, with thinner sheets being more flexible and harder tempers offering greater strength. Surface treatments like anodizing or painting can enhance appearance and corrosion resistance.</p>

- Q: Is this aluminium plate ceiling dark keel or bright keel?

- Although as upstairs said, now integrated ceiling are dark fitted keel. Can see your picture, elevation difference also has, should be bright install keel. This requires manufacturers and roof distribution. It is not important to open and install, but the key is where to enter such plates.If you think about the effect, consider getting the information from the scene.

- Q: How do aluminum sheets perform in high-temperature environments?

- Aluminum sheets perform well in high-temperature environments due to their excellent thermal conductivity and low melting point. Aluminum has a melting point of 660.3°C (1220.5°F), which is relatively low compared to other metals, allowing it to withstand high temperatures without melting. Additionally, aluminum has a high thermal conductivity, meaning it can effectively transfer heat away from the surface, preventing overheating and maintaining structural integrity. This characteristic makes aluminum sheets suitable for applications in industries such as aerospace, automotive, and construction, where high temperatures are encountered. However, it is important to note that prolonged exposure to extremely high temperatures can cause aluminum to weaken and lose some of its mechanical properties. Therefore, in extremely high-temperature environments, it may be necessary to consider alternative materials or use additional protective measures to ensure optimal performance.

- Q: What's the difference between laser cutting aluminum plate and stainless steel plate?

- The aluminum plate is higher than the stainless steel reflectivity, the focal point, the power, the speed are not the same, the general carbon dioxide laser does not have the anti - reflection lens, then had better not cut the aluminum plate, easy to burn the laser internal lens.

- Q: What is the typical lead time for ordering aluminum sheets?

- The lead time for ordering aluminum sheets can vary depending on factors such as the supplier, quantity of sheets ordered, and demand for aluminum. Generally, lead times can range from a few days to several weeks. If you are looking for standard-sized aluminum sheets that are readily available, the lead time is usually shorter, typically ranging from a few days to a week. Suppliers have these common sizes in stock and can ship them quickly. However, if you need custom-sized sheets or a large quantity that is not readily available, the lead time may be longer. In these cases, the supplier may need to source the aluminum, cut it to size, and process any necessary treatments or finishes. This process can take several weeks, especially if the supplier has a high volume of orders or if the aluminum needs to be imported. To determine the specific lead time for your order, it is important to communicate with the supplier. They can provide an estimated timeframe based on their production capacity, stock availability, and other factors that may affect the lead time.

- Q: Aluminum plate belongs to steel or non ferrous metal?

- Metal materials fall into two broad categories: ferrous and non-ferrous metals. What we usually call "iron and steel" is ferrous metal; copper and aluminum are nonferrous metals.

- Q: What's the difference between 6061 aluminum plate, 7075 aluminium plate and 6063 aluminum plate?

- 7075 T6 hardness in 150HB, hardness is highestUsually 6061 and 6063 can be common

Send your message to us

Aluminum Painted Embossed Diamond Aluminum Sheet - Diamond Embossed Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords