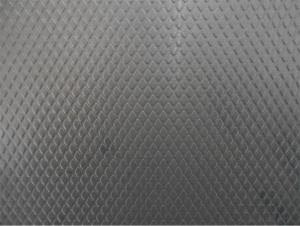

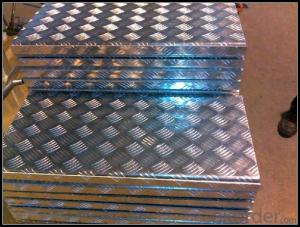

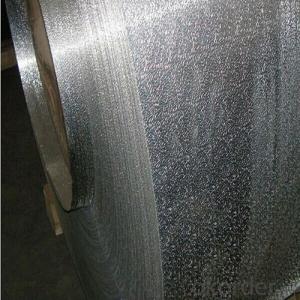

Embossed Aluminum Plate

Embossed Aluminum Plate Related Searches

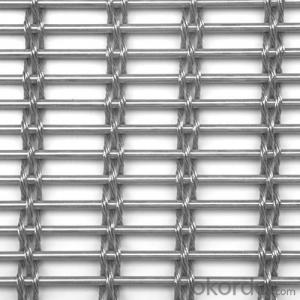

Embossed Aluminum Diamond Plate Embossed Aluminum Tread Plate Engraved Aluminum Plate Polished Aluminum Plate Embossed Aluminum Foil Extruded Aluminum Plate Textured Aluminum Plate Perforated Aluminum Plate Brushed Aluminum Plate Embossed Aluminum Coil Diamond Embossed Aluminum Sheet Ribbed Aluminum Plate Grooved Aluminum Plate Slotted Aluminum Plate Machined Aluminum Plate Wrought Aluminum Plate Milled Aluminum Plate Corrugated Aluminum Plate Aluminum Extrusion Plate Hardened Aluminum Plate Finned Aluminum Plate Bending Aluminum Plate Aluminum Wall Plate Aluminum Metal Plate Rolled Aluminum Plate Aluminum Dimond Plate Polished Aluminum Diamond Plate Aluminum Cover Plate Aluminum Checkered Plate Aluminum Cooking PlateEmbossed Aluminum Plate Supplier & Manufacturer from China

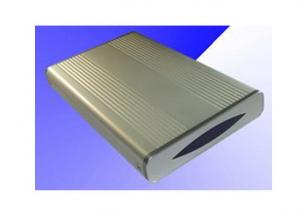

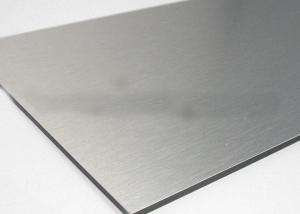

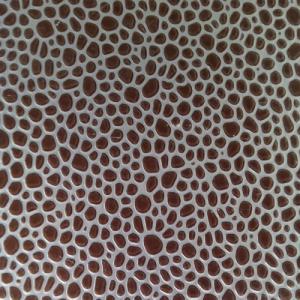

Embossed Aluminum Plate is a type of aluminum sheet material that features a raised pattern or design on its surface, offering both aesthetic appeal and functional benefits. These plates are manufactured by pressing the aluminum sheet through a die with the desired pattern, resulting in a textured surface that can be utilized in various industries and applications. The embossed finish not only enhances the visual appeal of the aluminum but also provides additional strength, durability, and resistance to wear and tear.The application and usage scenarios of Embossed Aluminum Plate are vast, ranging from architectural and construction purposes to automotive and transportation sectors. In architecture, it is often used for facades, cladding, and interior decoration due to its lightweight, corrosion-resistant properties, and modern appearance. In the automotive industry, embossed aluminum plates can be found in car body panels, engine components, and interior trims, where their strength and lightweight characteristics are highly valued. Additionally, embossed aluminum plates are used in the manufacturing of various consumer goods, such as appliances, furniture, and electronic devices, where their durability and design flexibility are advantageous.

Okorder.com is a leading wholesale supplier of Embossed Aluminum Plate, boasting a large inventory that caters to the diverse needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that their embossed aluminum plates meet the highest standards of performance and reliability. By offering a wide range of patterns, thicknesses, and finishes, Okorder.com enables customers to find the perfect Embossed Aluminum Plate for their specific applications and requirements.

Hot Products