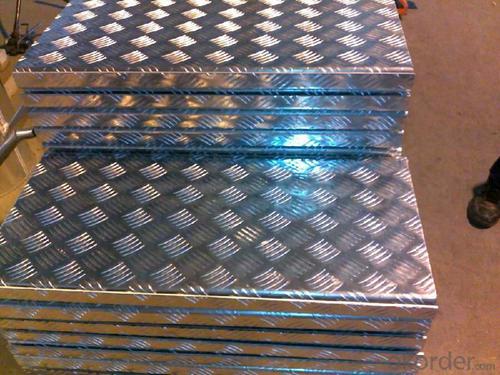

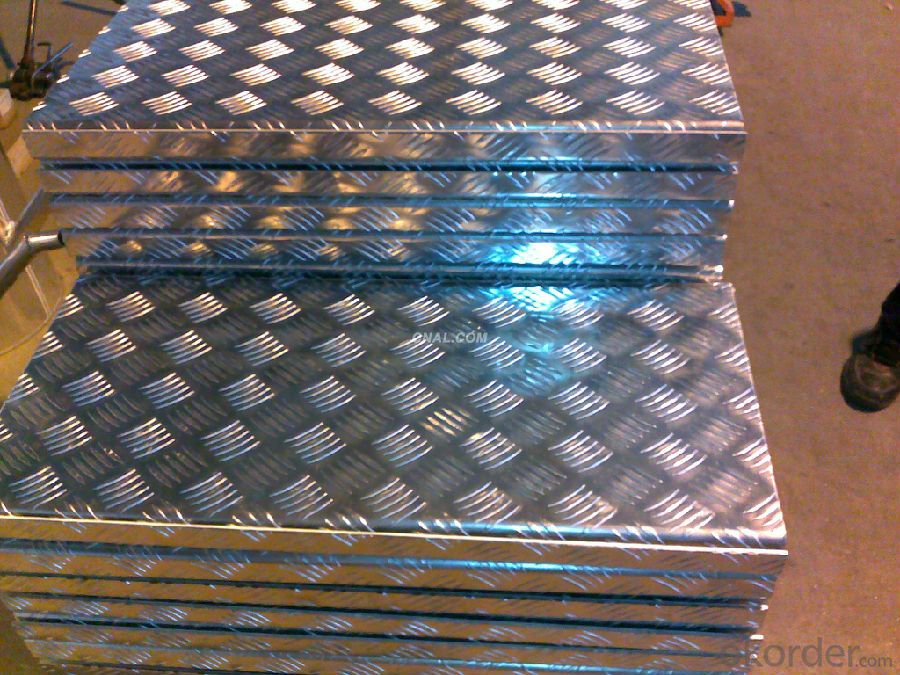

Sheets Aluminum Flooring Anti-Slip Checker Embossed Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Flooring Anti-slip Checker Embossed Sheet Plate

Description

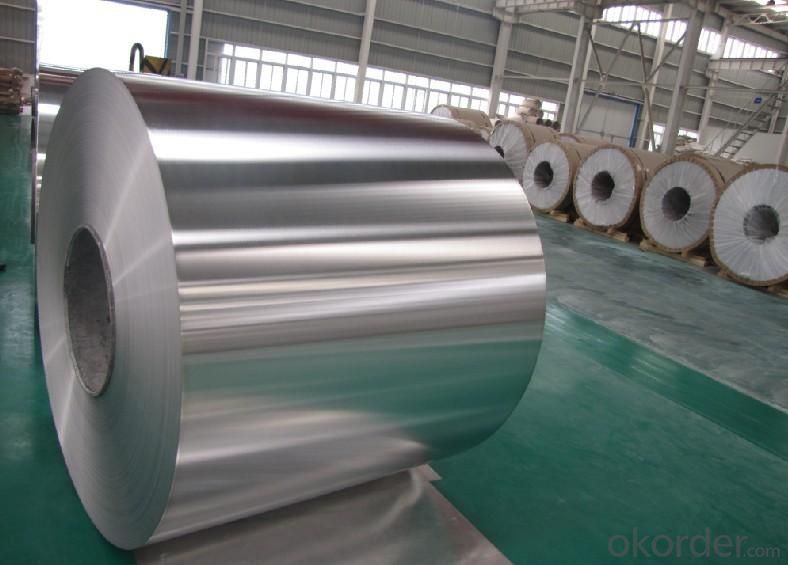

Aluminium Sheet | ||||||

Alloy | Thickness(mm) | Width(mm) | Length(mm) | Temper | DC or CC | |

1050,1060,1070,1100,1235 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

4.0-150 | 1000-1900 | H112,H111 | DC | |||

3003,3004,3105 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

4.0-150 | 1000-1900 | H112,H111 | DC | |||

5052,5083,5754 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC | |

4.0-150 | 1000-1900 | H112, H111 | DC | |||

8011 | 0.08-0.20 | 400-1500 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC | |

Packing | Export standard wooden packing | |||||

Application | Mainly in Construction , decoration, PCB materials, cover material, piping, refrigeration, air conditioner, automobile, etc. | |||||

MOQ | 5MT | |||||

Kind attention | Specifications can be customized as the customer’s requirements. | |||||

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: Does anyone know how to polish aluminum on a motorcycle that isn't too expensive to do?

- MOTHERS okorder one to do the polishing....then use a fresh one to buff the aluminum. Trust me on this one.....this is the ONLY polish I use on custom bikes.....with this stuff, you can make aluminum look almost like chrome!!!

- Q: This aluminum is on a mobile home. I trying to repaint it and there is alot of areas were rust has ate the metal away. Especially in the seams. How can I get rid of the rust that already exists and stop it from coming back.

- Uh......... aluminum doesn't rust. Has to be some iron in there somewhere.

- Q: Are 101 aluminum sheets suitable for decorative purposes?

- Yes, 101 aluminum sheets are suitable for decorative purposes. They offer a sleek and modern look, are lightweight, and can be easily customized or shaped to create various decorative elements.

- Q: Should I purchase a camper made out of aluminum/wood or a fiberglass?I'm looking to purchase a small camper, approx 18', to tow on the back of my SUV. It's a 2011 Wildwood camper. However, I hear campers made out of aluminum and wood aren't very good because the wood can ruin in time and the aluminum can rust, etc. I hear fiberglass campers are better? Anyone have any knowledge or experience with this? Also, any thoughts or advice with brands/models? And about the Wildwood? Thanks in advance.

- Aluminum is lighter so it offers economies over the life of the trailer. The Airstream has been built almost as long as I've been around. It is true that the wood does rot And some care is needed to stop the occasional leak. Fiberglass is heaver and has it's own maintenance issues. I've no experience with the Wildwood. What I do know is that motor homes are dirt cheap right now. You might think about taking advantage of the economy and pick-up a motor home at a bargain.

- Q: Are 101 aluminum sheets suitable for chemical storage tanks?

- No, 101 aluminum sheets are not suitable for chemical storage tanks as they lack the necessary corrosion resistance for handling and storing chemicals.

- Q: What are the advantages of using 101 aluminum sheets over other materials?

- One advantage of using 101 aluminum sheets is their high strength-to-weight ratio, making them lightweight yet durable. Additionally, aluminum is highly resistant to corrosion, making it suitable for outdoor applications without the need for additional protective coatings. Aluminum sheets are also easy to work with due to their malleability, allowing for various forming and fabrication processes. Lastly, aluminum is a highly recyclable material, making it an environmentally friendly choice.

- Q: How much should I be charged to have aluminum siding installed? I have a two floor single family home which is detached. I also would want new gutters installed and soffets (i think that is what they are called). One company estimated 12k and another said 10K. This would entail just putting the siding over the original siding. Any answers are appreciated.

- You have no say in the matter. The insurance company is paying the contractor to remove and dispose of the old siding. They don't care if the contractor makes a few hundred bucks selling the siding as scrap and neither should you.

- Q: Are aluminum sheets suitable for cladding?

- Aluminum sheets are indeed appropriate for cladding purposes. The utilization of aluminum as a cladding material is widely favored due to its numerous benefits. Firstly, its lightweight nature facilitates easier handling and installation. This leads to a reduction in the overall weight of the cladding system and a minimization of structural loading. Secondly, aluminum showcases exceptional durability and resistance to corrosion, rendering it suitable for both interior and exterior applications. Additionally, it possesses weather-resistant qualities, ensuring that the cladding remains in optimal condition even in harsh climates. Furthermore, aluminum is an incredibly versatile material that can be effortlessly shaped and fabricated, thus allowing for a diverse range of design options. It may be painted or coated with various finishes to enhance its appearance and provide additional protection. Moreover, aluminum cladding necessitates minimal maintenance, as it does not require frequent cleaning or painting. In summary, aluminum sheets are an exceptional choice for cladding due to their lightweight nature, durability, versatility, and low maintenance requirements.

- Q: Are aluminum sheets suitable for marine hulls?

- Yes, aluminum sheets are suitable for marine hulls. Aluminum is a popular choice for boat construction due to its many advantageous properties. Aluminum is lightweight, which allows for better fuel efficiency and increased speed. It is also highly resistant to corrosion, making it ideal for prolonged exposure to saltwater. Additionally, aluminum offers excellent strength and durability, ensuring the structural integrity of the hull. Moreover, aluminum can be easily formed into intricate shapes, allowing for innovative hull designs. Overall, aluminum sheets are a reliable and efficient choice for marine hulls, providing a strong and corrosion-resistant structure that enhances the performance and lifespan of the boat.

- Q: Can aluminum sheets be bent or formed?

- Indeed, it is possible to bend or shape aluminum sheets. Aluminum, being a remarkably malleable and ductile metal, can be effortlessly molded or bent without fracturing. This attribute renders it a favored option for a wide range of purposes, including the production of automotive components, aircraft structures, and household products. Diverse techniques, such as press braking, roll bending, and stretch forming, can be employed to bend or shape aluminum sheets. By utilizing these methodologies, the aluminum sheets can be formed into diverse angles or curves to fulfill precise design prerequisites.

Send your message to us

Sheets Aluminum Flooring Anti-Slip Checker Embossed Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords