1 8 Aluminum Checker Plate

1 8 Aluminum Checker Plate Related Searches

1/8 Aluminum Checker Plate 1 8 Aluminum Plate 4x8 Aluminum Checker Plate 4 X 8 Checker Plate Aluminum 1 8 Inch Aluminum Plate 1 8 Thick Aluminum Plate Aluminum Plate 1 8 Thick 1 4 Aluminum Checker Plate 1 8 Inch Thick Aluminum Plate Aluminum 1/8 Plate 1 8 In Aluminum Plate 1 8 Aluminum Diamond Plate Checker Plate Aluminum 1/8 Aluminum Plate Bending 1 8 Aluminum Plate 1/8 Inch Aluminum Plate 1/8 Thick Aluminum Plate 8 Inch Aluminum Plate Polished Aluminum Checker Plate Aluminum Plate 1/8 Thick Aluminum Plate 1/8 5 8 Aluminum Plate 1/8 Inch Thick Aluminum Plate Aluminum Checkered Plate 1 8 Inch Aluminum Diamond Plate 3 8 Thick Aluminum Plate 3 8 Inch Aluminum Plate 1 8 Diamond Plate Aluminum Sheet 3 8 Aluminum Plate 1 8 Black Aluminum Diamond Plate1 8 Aluminum Checker Plate Supplier & Manufacturer from China

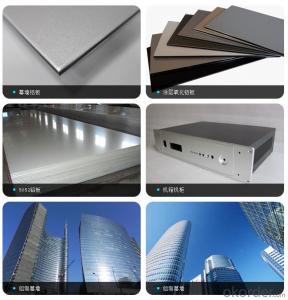

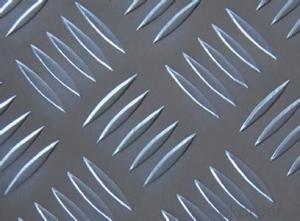

1/8 Aluminum Checker Plate is a type of aluminum sheet material characterized by its diamond-shaped pattern, providing both slip resistance and durability. This product is made from high-quality aluminum and is known for its strength, lightweight, and corrosion resistance properties. It is widely used in various industries due to its versatility and functionality.The 1/8 Aluminum Checker Plate is commonly utilized in construction, automotive, marine, and industrial applications. It serves as a protective flooring, walkway, and platform cover in areas where slip resistance and durability are essential. Additionally, it is used for ramps, truck beds, and various other surfaces that require a non-slip surface. Its lightweight and corrosion-resistant nature make it an ideal choice for environments where moisture and heavy foot traffic are prevalent.

Okorder.com is a reputable wholesale supplier of 1/8 Aluminum Checker Plate, offering a vast inventory of this product to cater to the needs of various industries. With their extensive selection and competitive pricing, customers can rely on Okorder.com to provide high-quality 1/8 Aluminum Checker Plate for their specific applications and requirements.

Hot Products