6061 Aluminum Thick Plate for mold production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

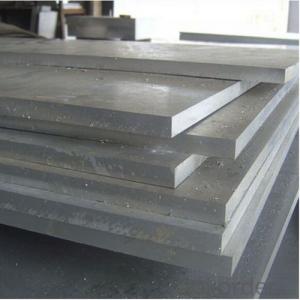

1.Structure of Aluminum Thick Plate for mold production

The alloy 6061 has very good welding characteristics and may be welded by all of the common welding techniques. Gas tungsten arc welding is generally used for thin sections and gas metal arc welding is used for heavier sections.Commonly used in the manufacture of heavy-duty structures requiring good corrosion resistance, truck and marine components, railroad cars, furniture, tank fittings, general structural and high pressure applications, wire products, and in pipelines.

2.Main Features of Aluminum Thick Plate for for Boat and Lighting:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

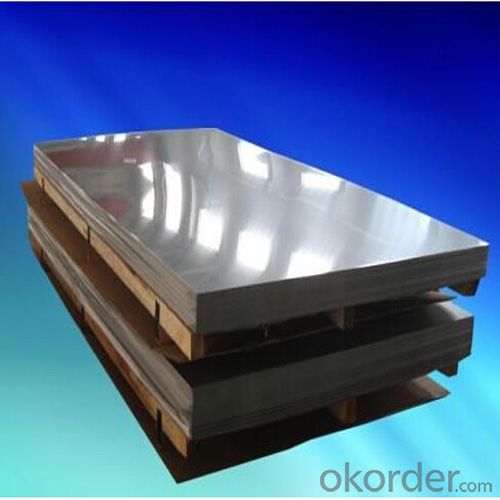

3. Aluminum Thick Plate Images:

4. Aluminum Thick Plate for for Boat and Lighting Specification:

Chemical Composition Limits for Aluminum Alloys

Composition in percent by weight according to The Aluminum Association. The values associates maximum limits unless shown as a range or a minumum.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others Each | Others Total | Al. Min. |

| 6061 | 0.40- 0.8 | 0.7 | 0.15- 0.40 | 0.15 | 0.8- 1.2 | 0.04- 0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

| 7075 | 0.40 | 0.50 | 1.2-2.0 | 0.30 | 2.1- 2.9 | 0.18- 0.28 | 5.1- 6.1 | 0.20 | 0.05 | 0.15 | Rem. |

| 2024 | 0.50 | 0.50 | 3.8-4.9 | 0.30-0.9 | 1.2- 1.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchanging experience with several quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes and video,we will be responsible.

- Q: Is it possible to utilize aluminum sheets in the interior design of vehicles?

- <p>Yes, aluminum sheets can be used for car interiors. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications such as door panels, dashboards, and trim. Aluminum's malleability allows for easy shaping into complex designs, and it can be finished in various ways to match the aesthetic of the vehicle's interior. Additionally, its strength-to-weight ratio contributes to fuel efficiency and performance. However, it's important to consider the specific alloy and treatment of the aluminum to ensure it meets safety and comfort standards.</p>

- Q: What is the surface finish of 101 aluminum sheets?

- The surface finish of 101 aluminum sheets can vary depending on the specific manufacturing process and desired application. However, common surface finishes for 101 aluminum sheets include mill finish, brushed finish, anodized finish, and painted finish. Mill finish refers to the raw, untreated surface of the aluminum sheet, which may have some minor imperfections or scratches. Brushed finish is achieved by brushing the surface of the sheet with a fine abrasive material, resulting in a smooth, satin-like appearance. Anodized finish involves an electrochemical process that forms a protective oxide layer on the surface of the aluminum, providing enhanced durability and corrosion resistance. Painted finish, on the other hand, involves applying a layer of paint onto the aluminum sheet to provide color and additional protection. Ultimately, the choice of surface finish for 101 aluminum sheets depends on the desired aesthetic, functional, and environmental requirements of the application.

- Q: Can aluminum sheets be embossed or engraved?

- Aluminum sheets have the capability to be embossed or engraved. The act of embossing entails the formation of a raised design or pattern on the aluminum sheet's surface, whereas engraving involves the cutting or etching of a design into the surface. These techniques are applicable for incorporating decorative or functional elements into aluminum sheets. In numerous industries, such as automotive, aerospace, signage, and architectural applications, embossed or engraved aluminum sheets are commonly employed. The process of embossing or engraving aluminum sheets typically necessitates the utilization of specialized machinery or tools to achieve the desired design.

- Q: Is it suitable to use aluminum windows in areas with cold weather conditions?

- <p>Yes, you can use aluminum windows in cold climates, but there are considerations. Aluminum is a good conductor of heat, which can lead to heat loss in cold weather. To mitigate this, insulated glass units and thermally broken frames can be used. These designs slow down heat transfer, making aluminum windows more energy-efficient in cold climates. Additionally, proper sealing and weatherstripping are crucial to prevent drafts and ensure the windows perform well in low temperatures.</p>

- Q: Can aluminum sheets be used for battery casings?

- Yes, aluminum sheets can be used for battery casings. Aluminum is a commonly used material in the manufacturing of battery casings due to its lightweight, corrosion-resistant, and durable properties. It also allows for efficient heat dissipation, making it suitable for various types of batteries.

- Q: How much is a square inch of a millimeter aluminum plate?

- The weight of 2.73 kg / square meter5 Series refers to magnesium as the main alloy element, that is, aluminum magnesium alloy.

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Yes, aluminum sheets can be bent or formed without cracking or breaking, as long as proper techniques such as annealing and using appropriate tooling are employed.

- Q: This question asks for guidance on selecting a trustworthy supplier for purchasing aluminum sheets.

- <p>To choose a reliable supplier of aluminum sheets, consider the following: Check their reputation by reading reviews and testimonials. Ensure they have a valid certification and adhere to industry standards. Evaluate their product quality by requesting samples or visiting their production site. Assess their delivery times and reliability. Confirm they offer competitive pricing without compromising on quality. Look for suppliers with good customer service and after-sales support. Finally, consider their financial stability and ability to fulfill large orders.</p>

- Q: Excuse me: what kind of aluminum sheet is the cheapest? Which materials are more expensive?

- According to the general arrangement from low to high prices:The first 1 lines are the cheapest, such as 1050.1060.1070..1100, which is pure aluminum;Second, 3 Department prices, such as 3003.3004.3104, etc..

- Q: What is the weight per square foot of 101 aluminum sheets?

- The weight per square foot of 101 aluminum sheets varies depending on the thickness of the sheets. Please provide the thickness of the aluminum sheets to determine the weight per square foot accurately.

Send your message to us

6061 Aluminum Thick Plate for mold production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords