6061 T6 Aluminum Plain Sheet for Construction and Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

6061 T6 Aluminum Plain Sheet for Construction and Industry

l Product Introduction

Aluminium has a lot of salient properties that the other metals do not have. It is very strong, yet it is not very heavy. Like other metals, it conducts electricity and heat to a moderate degree. Most industries require aluminium sheets for various purposes. Aluminium can be easily beaten into sheets because of its high malleability. It has the preoperty of light weight, medium strength, easy-forming and anti-corrosion.

l Product Description

1)Alloy: 6061

2)Temper: H18 .H24 .H32 .H112 T4 T6 T651 O

3)Thickness: 0.2MM-20MM

4) Width : up to 1500mm

5) Good plasticity and conductivity

6) Dimensions can be produced as per clients' specifications

7) Generally used for industrial and construction applications

Product | Aluminum sheet |

Alloy | 1100 1050 1060 3003 3004 3105A 5005 5052 5754 5083 6061 6063 6082 8011 |

Temper | H14, H16, H18, H19, H24, H26,H32,H112,T4,T6,T651,O |

Width | 900—1500mm |

Thickness | 0.3—20mm |

Payment | L/C or T/T |

Packaging | Standard export packing |

Delivery time | In 20-30days after receiving L/C or T/T |

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

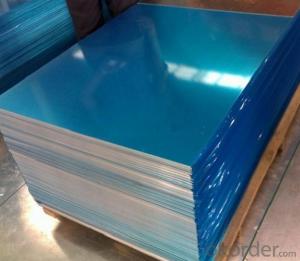

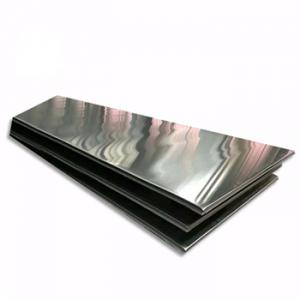

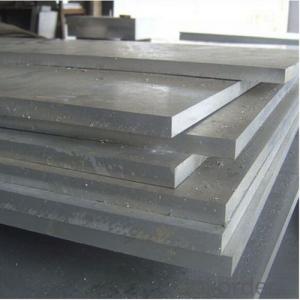

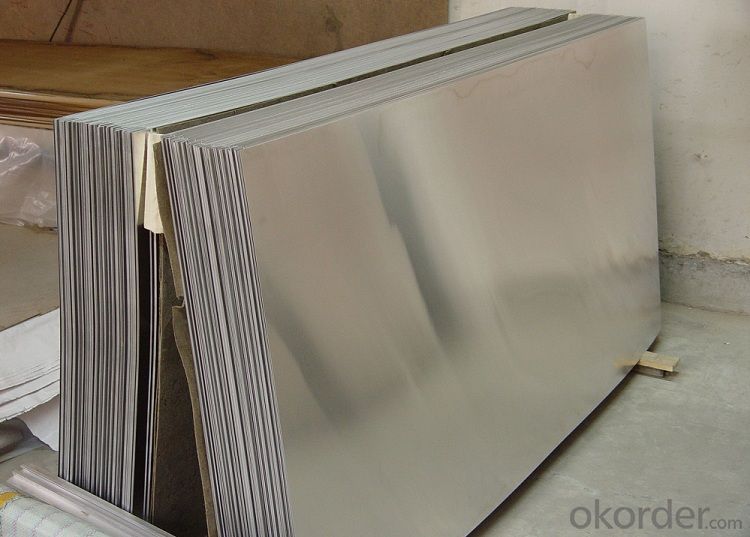

l Products Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: (1) Aluminum is malleable. (2) Aluminum reacts with sulfuric acid.(3) Aluminum conducts an electric current.(4)Aluminum has a density of 2.698 g/cm3 at STP.Explain why.

- statement 2 because it describes the nature of a reaction involving aluminium. The reaction is governed by its chemical properties such as the number of electrons is contains and its ability to for ions.

- Q: Do 101 aluminum sheets have any specific sound or vibration damping properties?

- Yes, 101 aluminum sheets have specific sound and vibration damping properties. Aluminum is known for its excellent damping characteristics, meaning it can effectively absorb or dampen vibrations and reduce noise levels. This is due to its high density and stiffness, which allow it to dissipate vibrational energy. Additionally, aluminum sheets can be further enhanced by applying sound-damping coatings or treatments, such as adhesive-backed damping sheets or constrained layer damping materials. These treatments can further improve the sound and vibration damping properties of 101 aluminum sheets, making them a popular choice in various industries where noise reduction and vibration control are important considerations, such as automotive, aerospace, and construction.

- Q: Can 101 aluminum sheets be used in the production of solar reflectors?

- Yes, 101 aluminum sheets can be used in the production of solar reflectors. Aluminum is a widely used material in the solar industry due to its high reflectivity and durability. The number 101 refers to the specific alloy composition of the aluminum, which usually indicates that it is a pure aluminum or a low alloy variant. Pure aluminum has excellent reflective properties, making it ideal for solar reflectors that need to efficiently redirect sunlight onto solar cells or panels. However, it is important to consider other factors such as thickness, surface finish, and any additional coatings or treatments that may be required for optimal performance in solar reflector applications.

- Q: My frame snapped and I want to fix it by welding it back together. In order to do that, I need to know what all is in the aluminum.

- You can NOT weld back an aluminum frame unless you have the facilities to anneal and heat treat the frame again. Rewelding without the post treatments will result in a very soft area around the new weld causing sudden catastrophic failure... this means if you are riding it could fail at any time causing injury or death. EDIT: Wait just a durn minute. The 2100 and 2300 had carbon fiber tubes bonded to aluminum lugs and stays. If your bike failed then you ABSOLUTELY should not try to weld it. The heat from welding (even if you had post treatment facilities) would destroy the bond between the CF and aluminum. Fair warning- cut the frame apart and throw it away.

- Q: What is the cost of aluminum sheet compared to other metals?

- The price of aluminum sheet can differ from other metals depending on various factors like market conditions, availability, and specific metal grades. Generally, aluminum sheet is considered more economical than stainless steel, copper, and brass, among others. This is primarily because aluminum is abundant in the Earth's crust and the extraction and refining processes are relatively inexpensive. In addition, aluminum is often lighter in weight compared to other metals, making it a cost-effective choice for industries where weight is a concern, such as transportation. However, it should be noted that the cost of aluminum can change due to global supply and demand, tariffs, and other economic factors. Therefore, it is advisable to check current market prices and consult with suppliers or metal experts for accurate and up-to-date pricing information.

- Q: Can aluminum sheets be used for air ducts?

- Yes, aluminum sheets can be used for air ducts. Aluminum is a commonly used material for air ducts due to its lightweight and durable properties. It is resistant to corrosion, which makes it a suitable choice for HVAC systems. Aluminum sheets are often used to fabricate air ducts as they can be easily bent and shaped to fit the required dimensions. Additionally, aluminum has good thermal conductivity, allowing for efficient heat transfer within the ducts. Overall, using aluminum sheets for air ducts is a practical and effective choice.

- Q: Can aluminum sheets be used for decorative ceiling panels?

- Yes, aluminum sheets can be used for decorative ceiling panels. Aluminum is a versatile material that can be easily shaped, colored, and textured, making it ideal for creating visually appealing and modern ceiling designs. Additionally, aluminum is lightweight, durable, and resistant to corrosion, making it a practical choice for long-lasting decorative ceiling panels.

- Q: What are the different methods of punching aluminum sheets?

- There are several methods of punching aluminum sheets, including manual punching using handheld tools, mechanical punching using presses, and CNC punching using computer-controlled machines.

- Q: Can aluminum sheets be anodized for improved hardness?

- Yes, aluminum sheets can be anodized to significantly improve their hardness. Anodizing is an electrochemical process that thickens the natural oxide layer on the surface of the aluminum, creating a durable and corrosion-resistant coating. This process enhances the hardness and durability of the aluminum sheets, making them more resistant to wear, scratches, and other forms of damage.

- Q: Can aluminum sheet be used for electronic components?

- Indeed, aluminum sheet is a viable option when it comes to electronic components. This versatile material boasts numerous advantages for electronic applications. Not only is it lightweight, but it also exhibits exceptional thermal conductivity and corrosion resistance. These characteristics render it suitable for a wide range of electronic components, including heat sinks, enclosures, connectors, and printed circuit boards (PCBs). The machinability, formability, and weldability of aluminum sheets further enable efficient manufacturing processes. Moreover, aluminum proves to be a cost-effective alternative to materials like copper or steel. Nevertheless, it is crucial to acknowledge that aluminum may not be suitable for all electronic components, particularly those necessitating high electrical conductivity or magnetic shielding.

Send your message to us

6061 T6 Aluminum Plain Sheet for Construction and Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords