3 8 6061 Aluminum Plate

3 8 6061 Aluminum Plate Related Searches

3/8 6061 Aluminum Plate 1 4 6061 Aluminum Plate Aluminum Plate 6061 1 2 6061 Aluminum Plate Aluminum 6061 Plate 6061 Aluminum Alloy Plate T6061 Aluminum Plate 6061-T6 Aluminum Plate 6061 0 Aluminum Plate 6061 T6 Aluminum Plate Bending 6061 Aluminum Plate 1/2 6061 Aluminum Plate 1/4 6061 Aluminum Plate 6061 Aluminum Tread Plate 3 8 Aluminum Plate 6061 Aluminum Plate 1 2 3 8 Thick Aluminum Plate 6061 Aluminum Tooling Plate 6061 Aluminum Diamond Plate 3 8 Inch Aluminum Plate 6061 T651 Aluminum Plate 6061-T651 Aluminum Plate 6060 Aluminum Plate 6061 Aluminum Plate Thickness Metric 6061 Aluminum Plate 3 8 Inch Thick Aluminum Plate Aluminum Plate 6063 6063 Aluminum Plate 6061 Aluminum Plate For Sale 3/8 Aluminum Plate3 8 6061 Aluminum Plate Supplier & Manufacturer from China

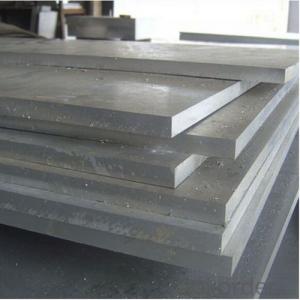

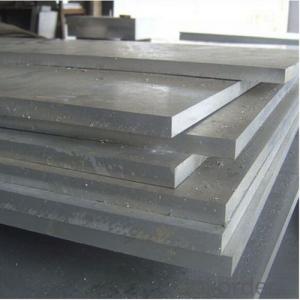

The 3/8 6061 Aluminum Plate is a popular choice among various industries due to its excellent strength-to-weight ratio, good workability, and corrosion resistance. This type of aluminum plate is commonly used in applications such as aircraft parts, marine components, and architectural structures, where its lightweight and durable properties are highly valued.The 3/8 6061 Aluminum Plate is widely utilized in various industries because of its versatile properties, making it suitable for a broad range of applications. It is particularly favored in sectors that require lightweight, strong, and corrosion-resistant materials, such as aerospace, automotive, and construction. Its ability to withstand harsh environments and maintain its integrity over time has made it a go-to choice for many professionals.

Okorder.com is a reputable wholesale supplier of 3/8 6061 Aluminum Plate, offering a vast inventory to cater to the needs of businesses and individuals alike. With a commitment to providing high-quality products at competitive prices, Okorder.com has established itself as a trusted source for this aluminum plate, ensuring that customers receive the best value for their investment.

Hot Products