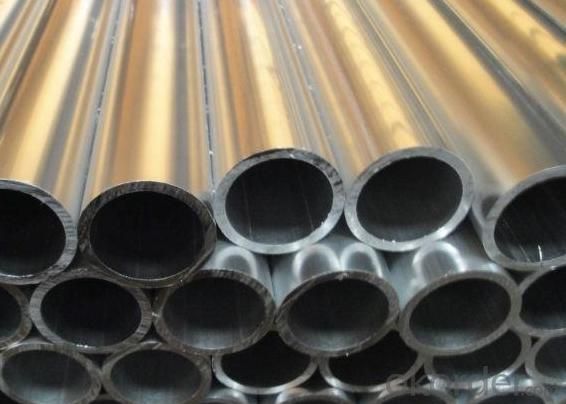

Aluminum Pipes 1060

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Pipe 1060:

1.Specifications of aluminium pipe 1060:

1)Alloy:1060;

2)Wall thickness : 0.4mm-80mm ;

3)Outer diameter : 10-900mm ;

4)Length : 6m-9m.

2.Application of aluminium pipe 1060:

aluminum window, door, curtain wall, hand railing, normal aluminum profile, decorative and industrial aluminum profile

3.Features of aluminium pipe 1060:

High weather resistance anti scratch anticorrosion and good weather resistance subtle edges and elegant appearance and easy processing and installation high brightness and hardness.

4.Packaging:

protection foam heat contracted plastic film,Wooden packing , Metal pallet

- Q: Air conditioning copper aluminum tube how to connect? It's broken at the copper aluminum pipe joint. What should I do?

- This welding is a lot of trouble. It's not worthwhile to weld out the refrigerant. How expensive is the refrigerant now?. Change a pair of aluminium tube, also be 20 yuan or so

- Q: How to repair the surface defects of aluminum pipe

- Method: to hand percussion pits with oxyacetylene flame annealing, after cooling, use hand hammer into the aluminum oblate tube, estimated knocking position try to knock, knock point and observe from the outside, adjusted and confirmed the knock point after the afterburner struck, until the elimination of pits. If it is difficult to strike in the middle, it is expected to be hardened by metal hammering. It must be reheated and annealed again, and then continue after cooling. The method is generally applicable to the repair of the larger diameter aluminum tube and the hand length of the pit. Not suitable for trimming of flattening defects

- Q: The hollow aluminum existing 334*20*1220, two middle circle, one direction is about 500 for the long drum hit, surface hardness is 100HB, what's the way to the middle place into circular drum!

- Aluminum tube is a kind of nonferrous metal pipe, which is made of pure aluminum or aluminum alloy and is extruded into a hollow metal tube with longitudinal length. English Name: alumin (I) um tube; alumin (I) um pipe may have one or more closed vias,

- Q: Can aluminum pipes be used for solar panel installations?

- Certainly, solar panel installations can utilize aluminum pipes. Aluminum is widely preferred in mounting structures for solar panels because of its lightweight nature, resistance to corrosion, and durability. Frequently, aluminum pipes are employed in constructing the framework or support structures of solar panels, ensuring stability and strength while minimizing the system's overall weight. Furthermore, aluminum is an economical material, which is why it is favored by numerous solar panel installers.

- Q: Now there are two kinds of air-conditioning connections, one is copper aluminum pipe connection, one is pure copper pipe connection, copper aluminum pipe connection quality, OK?

- In contrast or pure copper, from corrosion resistance, pressure resistance, heat conduction, good toughness is pure copper, aluminum brass appears is actually in order to reduce the cost of manufacturing businesses, now is about social science has developed, but in the end is progress or retrogression?

- Q: Are aluminum pipes suitable for underground installations?

- Aluminum pipes, indeed, prove to be a fitting choice for underground installations. Their versatility and durability make them an ideal material for such applications. To begin with, aluminum pipes possess a lightweight quality that simplifies their handling and installation when compared to materials like steel or cast iron. This attribute not only reduces transportation expenses but also minimizes the requirement for heavy machinery during the installation process. Moreover, aluminum exhibits exceptional resistance to corrosion. It forms a natural protective oxide layer on its surface, rendering it highly impervious to rust and other forms of corrosion. This reliability makes aluminum pipes an excellent option for underground installations, where they will be subjected to moisture and varying soil conditions. Furthermore, aluminum is non-magnetic, making it appropriate for underground installations in areas where magnetic interference might be a concern, such as in close proximity to power lines or sensitive electronic equipment. Additionally, aluminum pipes possess commendable thermal conductivity, facilitating efficient heat transfer. This proves beneficial for specific underground applications like geothermal systems or underground heating and cooling pipes. However, it is crucial to note that aluminum pipes may not be suitable for every underground installation. Factors like soil conditions, water chemistry, and the presence of corrosive elements should be taken into account before selecting aluminum as the material for underground pipes. It is advisable to consult with a professional engineer or contractor experienced in underground installations to ensure the appropriateness of aluminum pipes for a specific project.

- Q: we have been cutting copper tube, now cutting aluminum tube, existing cutting machine cutting aluminum pipe burr is too big

- You cut the copper tube with plain saw blades, don't you? I don't know the thickness of the aluminum tube you cut If it is a thin wall tube, the blade will suggest making tooth tooth inclination increased, let teeth widened; if the wall thickness of pipes, apply with tungsten circular saw to cut.

- Q: Where does the refrigerator copper tube come from? How to distinguish

- Is the pipe next to the compressor copper?Chasing the answerIs this tube above connected to the tube in the refrigerator sealed with it, see.

- Q: What is the typical wall thickness of aluminum pipes?

- The typical wall thickness of aluminum pipes can vary depending on the specific application and industry standards. However, in general, aluminum pipes typically have a wall thickness ranging from 1/16 inch to 1/4 inch. The exact thickness will depend on factors such as the diameter of the pipe, the intended use, and the required strength and durability. It is important to consult industry standards and specifications or seek guidance from a professional engineer or supplier to determine the appropriate wall thickness for a specific project or application.

- Q: What is the difference between the 6061-T6 aluminum pipe and the common aluminum pipe?

- The T6 state is after the heat treatment of aluminum (solution treatment after artificial aging state), sold on the market are generally after heat treatment of aluminum, some without considering the cost of materials and heat treatment processing and sale, in terms of hardness to lower than T6

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Pipes 1060

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords