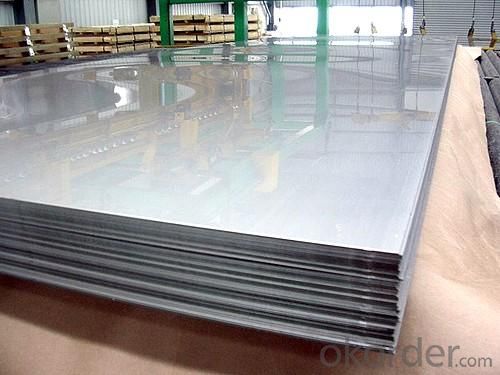

4x8 Grate Hot Sale Alloy 1100 1050 1060 3003 3004 5052 8011 Solid Aluminum Sheet Aluminum Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | Temper: | Type: | |||

| Application: | Thickness: | Width: | |||

| Surface Treatment: | Alloy Or Not: | Place of Origin: | |||

| Brand Name: | Model Number: | Class: | |||

| Color: | Alloy number: |

Packaging & Delivery

| Packaging Detail: | aluminium sheet Standard Package Wooden,Plastic,Paper Package |

| Delivery Detail: | 10-20days after deposit |

Specifications

aluminium sheet

1.Good strength of extension

2.Better tensile yield strength

3.Best elongation

aluminium sheet

Supplier the best quality of aluminium sheet

Advantages:

1.Good strength of extension

2.Better tensile yield strength

3.Best elongation

Applications:

chemical process plant equipment,food industry containers,architectural flashings, lamp reflectors, cable sheathing

Specification:

Main Products | Alloy Number | Hot rolling finial Thickness | Cold mill finial Thickness | Hot rolling finial Width | Cold mill finial Width |

1xxx Series | 1235 1050 1060 1100 | 2-8mm | 0.1-0.5mm | 900-2400mm | 1000-2400mm |

3xxxSeries | 3003 3004 3104 | 2-8mm | 0.1-0.5mm | 900-2400mm | 1000-2400mm |

5xxxSeries | 5052 5182 5083 5005 5754 | 2-8mm | 0.1-0.5mm | 900-2400mm | 1000-2400mm |

8xxxSeries | 8079 8011 | 2-8mm | 0.1-0.5mm | 900-2400mm | 1000-2400mm |

- Q: Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is lightweight, strong, and resistant to corrosion, making it an ideal material for building boats and ships. It also offers good thermal conductivity and is easily weldable, making it a popular choice in the marine industry.

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- Chemical transfer piping cannot rely on 101 aluminum sheets as they are unsuitable. The reactivity and corrosion propensity of aluminum make it generally unfit for handling specific chemicals. Industries like aerospace or construction prefer aluminum due to its lightweight nature and excellent thermal conductivity. However, for chemical transfer piping, it is wiser to opt for materials that possess corrosion resistance and can endure the specific chemicals being transported. Stainless steel, PVC, or high-density polyethylene (HDPE) are recommended alternatives.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of residential buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in residential buildings. They offer several advantages such as durability, resistance to weather and corrosion, and low maintenance. Aluminum is lightweight, which can reduce structural load, and it can be easily shaped and installed. Additionally, it has good thermal performance and can be combined with insulation for energy efficiency. However, it's important to consider the aesthetic appeal, as aluminum may not match the traditional look of some residential buildings, and ensure it meets local building codes and standards.</p>

- Q: What are the advantages of using 101 aluminum sheets over other materials?

- One advantage of using 101 aluminum sheets is their high strength-to-weight ratio, making them lightweight yet durable. Additionally, aluminum is highly resistant to corrosion, making it suitable for outdoor applications without the need for additional protective coatings. Aluminum sheets are also easy to work with due to their malleability, allowing for various forming and fabrication processes. Lastly, aluminum is a highly recyclable material, making it an environmentally friendly choice.

- Q: What is the weight of aluminum sheets per square foot?

- The weight per square foot of aluminum sheets may differ depending on the sheet's thickness or gauge. Typically, a 1/8 inch thick aluminum sheet weighs approximately 1.9 pounds per square foot. Nevertheless, thinner sheets tend to be lighter, whereas thicker sheets can be heavier. It is crucial to take into account the precise thickness of the aluminum sheet when calculating its weight per square foot.

- Q: This question asks for methods to maintain and repair aluminum sheets once they have been installed.

- <p>To maintain and repair aluminum sheets after installation, follow these steps: Regularly clean the surface with a soft cloth and mild detergent to remove dirt and grime. Avoid abrasive materials that can scratch the surface. For minor scratches or dents, use aluminum filler or touch-up paint that matches the sheet's color. Apply the filler or paint carefully, following the manufacturer's instructions. For more severe damage, consider hiring a professional to assess and repair the damage to ensure structural integrity. Always check for any signs of corrosion and address them promptly to prevent further damage. Regular maintenance will prolong the life of aluminum sheets and keep them looking their best.</p>

- Q: Can aluminum sheet be used for aerospace applications?

- Certainly, aluminum sheet finds application in the aerospace industry. Owing to its advantageous characteristics, including being lightweight, highly robust, and resistant to corrosion, aluminum is extensively employed in this sector. It is frequently utilized in the fabrication of aircraft fuselages, wings, and structural elements. Aluminum sheets are commonly employed in the production of aircraft panels, where their exceptional strength-to-weight ratio facilitates enhanced fuel efficiency and greater payload capacity. Furthermore, aluminum sheets offer versatility and suitability for a wide range of aerospace applications due to their ease of forming, machining, and welding.

- Q: 4.0mm five bars, aluminum plate, 4 aluminum plate, one ton, how many square?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liu Guangxi Henan Mingtai aluminum has the.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Certain applications can consider aluminum sheets as an alternative to glass. Aluminum sheets provide various benefits over glass, making them suitable for specific scenarios. To begin with, aluminum sheets possess lightweight and durable characteristics, making them an excellent choice for industries like aerospace or automotive, where weight is a concern. Conversely, glass is relatively heavy and brittle, limiting its usage in certain environments. Moreover, aluminum sheets exhibit exceptional resistance to corrosion, making them a suitable option for marine or coastal applications, where glass may deteriorate over time due to exposure to saltwater. Aluminum sheets also possess a high strength-to-weight ratio, enabling greater design flexibility and structural integrity compared to glass. Furthermore, aluminum sheets offer superior thermal insulation properties in comparison to glass. They provide improved resistance to heat transfer, which is advantageous in applications where temperature control is crucial, like the construction industry. Additionally, aluminum sheets can be more cost-effective than glass in specific applications. The production and installation costs of aluminum sheets are often lower than glass, making them a more economical choice for large-scale projects. However, it is important to acknowledge that glass retains its own unique properties and advantages, such as transparency and optical clarity. Glass also has better resistance to scratches and chemical corrosion when compared to aluminum sheets. In conclusion, while aluminum sheets can serve as a viable alternative to glass in certain applications due to their lightweight, durability, corrosion resistance, thermal insulation properties, and cost-effectiveness, the final decision between the two materials depends on the specific requirements and limitations of the application at hand.

- Q: I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- Sounds like someone was using a traditional, and overdrew and had the carbon arrow come off the rest just as they were releasing it... Thats the 1 and only way i can think of a bow shooter to get bits of a carbon arrow in their hand...That and using a high poundage bow and a low poundage spine carboned arrow

Send your message to us

4x8 Grate Hot Sale Alloy 1100 1050 1060 3003 3004 5052 8011 Solid Aluminum Sheet Aluminum Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords