4 X 4 Aluminum Plate

4 X 4 Aluminum Plate Related Searches

4x4 Aluminum Plate 4 Inch Aluminum Plate 4 X 8 X 1 4 Aluminum Plate 4 Mm Aluminum Plate 4 Aluminum Plate 1 4 Inch Aluminum Plate 4' X 8' X 1/4 Aluminum Plate 1 4 Aluminum Plate 3 4 Inch Aluminum Plate 1 4 Aluminum Plate 4x8 4x8 Aluminum Plate Aluminum Plate 4x8 3 4 Thick Aluminum Plate 1 4 Thick Aluminum Plate 1/4 Inch Aluminum Plate 4x8 1 4 Inch Thick Aluminum Plate 3 4 Aluminum Plate 1/4 Aluminum Plate 4x8 4 X 8 Diamond Plate Aluminum 3/4 Inch Aluminum Plate 4 X 8 Aluminum Diamond Plate 12 X 12 X 1 4 Aluminum Plate 3/4 Thick Aluminum Plate 1/4 Inch Aluminum Plate 3/4 Inch Thick Aluminum Plate 24 X 24 X 1/4 Aluminum Plate 3/4 Aluminum Plate 1/4 Plate Aluminum 1/4 Aluminum Plate Aluminum 1/4 Plate4 X 4 Aluminum Plate Supplier & Manufacturer from China

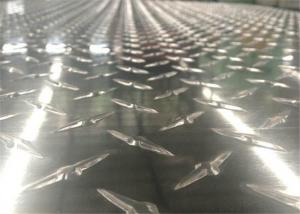

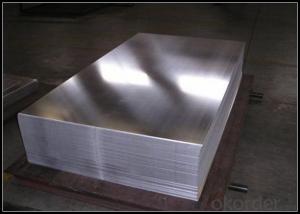

4 X 4 Aluminum Plate, a popular choice among construction and manufacturing industries, is known for its lightweight properties, corrosion resistance, and high strength. This versatile material is widely used in various applications, such as automotive parts, aerospace components, and architectural structures. Its durability and ease of fabrication make it an ideal option for projects requiring precision and efficiency.The 4 X 4 Aluminum Plate is utilized in numerous scenarios, including but not limited to, fabrication of brackets, frames, and panels. Its ability to withstand harsh weather conditions and maintain its structural integrity over time makes it a preferred choice for outdoor applications. Additionally, the 4 X 4 Aluminum Plate is often employed in the production of heat sinks and electrical components due to its excellent thermal conductivity and electrical insulation properties.

Okorder.com, a renowned wholesale supplier, boasts a vast inventory of 4 X 4 Aluminum Plate, catering to the diverse needs of clients across different industries. Their comprehensive range ensures that customers can find the precise specifications and dimensions required for their projects, making Okorder.com a go-to destination for high-quality aluminum plates.

Hot Products