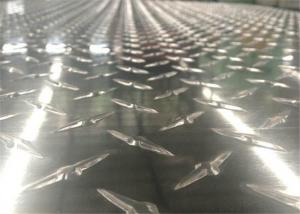

Aluminum Diamond Plate Sheets 4x8 - Orange Peel Pattern Aluminum Sheet Coil Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Common Aluminum Sheet Coil

1. Place of Origin: ZheJiang, China (Mainland)

2. Model Number: 1050/1060/3003/3004/5052/8011

3. Thickness: 0.20-20.0 mm

4. Width: 1000-1700 mm

Packaging & Delivery

1. Coating: Wooden Pallet for Exporting

2. Delivery Detail: 25-30 Days

Specifications

Aluminum Sheet

1. Alloy: 3003A1050/1060/3003/3004/5052/8011

3. Thickness (mm): 0.20-20.0

4. Width (mm): 1000 mm to 170 0mm, Customer Specific Width

5. Finish: Mill, Customer Specific Finish

Our main products are aluminum alloy thick sheet

PS/CTP plate (1050)

anodic oxidation / 3003/5052 (1060/1070)

automotive aluminum alloy (5754/6111/6061)

soldering material (3003/4004)

IT used materials (3003/5052)

the LED base material, material can (3004/3104)

the tank cover and TAB (5052/5182)

aluminous model with substrate (1100)

medicinal foil (8011)

household foil aluminum foil (1235) (8011)

Car Industry:

Alloy: 5182、5083、5754、5052、5042、6061、6063、6082

Feature: nice appearance, good formability, high safety factor, paint hardening effect is significant.

Product Name | Alloy | Usage |

Automotive sheet: interior panels | 1*** 3*** 5*** | Cars, automotive structural components |

Automotive sheet: structure | 1*** 3*** 5*** 6*** | Cars, automotive structural components |

Automotive sheet: housing,auto body | 3*** 5*** 6*** | Cars, automotive structural components |

Transportation Industry

Alloy: 1060、3003、5052、5754、5083、4104、6061、6016, etc..

Feature: High strength, excellent resistance to stress corrosion and welding performance.

Product Name | Alloy | Usage |

Coal car sheet | 1*** 3*** 5*** | Transporter application areas: coal car plate |

Thick aluminum sheet | 1*** 3*** 5*** 6*** | In industrial applications, such as aluminum cans tanker, auto body outer and inner plates |

Brazing sheet | 4*** composite panels | Oxygen equipment and automotive radiator |

Embossed aluminum sheet | 1*** 3*** 5*** | Nonslip floor decoration; nonslip floor; inside the vehicle with the non-slip floor |

- Q: Is it possible to recycle aluminum sheets multiple times?

- <p>Yes, aluminum sheets can be recycled again and again. The recycling process for aluminum is highly efficient, and it can be recycled indefinitely without losing any quality. This is due to the fact that aluminum retains its properties even after multiple recycling cycles. Each time aluminum is recycled, it can be melted down and reformed into new products, making it a sustainable and environmentally friendly material.</p>

- Q: I was hoping someone could explain aluminum corrosion with degreasers and cleaning formulas for automotive cleaning. This starts with, where is this aluminum (wheels)?, what types of cleaners?, do cleaners cause corrosion? Any insights would be appreciated.

- stick with an automotive brand cleaner most wheels are clearcoated to prtect the finish. I use 50/50 water and simple green to clean wheels and ive been detailing 20+ years

- Q: i want to a material which is similar in properties like aluminium which has similar casting properties and easily available.

- Aluminum is lousy for casting because it shrinks and tears. However you can add about 2% finely divided steel and get a useable alloy. It is better to use what everybody else uses: pot metal. Any junk yard can provide an endless supply of carburetor bodies which you can melt at fairly low temperatures and get nice strong castings. If you can locate some ancient floppy drives or dot matrix printers you will get a prettier alloy.

- Q: What are the different methods for joining aluminum sheets?

- There are several methods for joining aluminum sheets, including welding, riveting, adhesive bonding, and mechanical fastening. Welding involves melting and fusing the aluminum sheets together using heat, while riveting involves using metal fasteners to hold the sheets together. Adhesive bonding uses specialized adhesives to create a strong bond between the sheets, and mechanical fastening involves using screws, bolts, or other mechanical devices to secure the sheets together.

- Q: Can aluminum sheet be used for chemical processing?

- Yes, aluminum sheet can be used for chemical processing. Aluminum has excellent corrosion resistance and is often used in chemical processing industries for various applications such as storage tanks, reaction vessels, and heat exchangers.

- Q: This question asks for guidance on selecting a trustworthy supplier for purchasing aluminum sheets.

- <p>To choose a reliable supplier of aluminum sheets, consider the following: Check their reputation by reading reviews and testimonials. Ensure they have a valid certification and adhere to industry standards. Evaluate their product quality by requesting samples or visiting their production site. Assess their delivery times and reliability. Confirm they offer competitive pricing without compromising on quality. Look for suppliers with good customer service and after-sales support. Finally, consider their financial stability and ability to fulfill large orders.</p>

- Q: What are the different types of surface treatments available for aluminum sheets?

- Aluminum sheets can be treated in a variety of ways to achieve specific purposes and unique characteristics. Anodizing, painting, powder coating, and polishing are some of the most commonly used surface treatments for aluminum sheets. Anodizing involves the creation of a thick oxide layer on the surface of the aluminum sheet. This treatment not only enhances the appearance by providing a range of colors but also increases corrosion resistance and durability. Anodized aluminum sheets are widely utilized in architecture, automotive parts, and electronics. Painting is another popular surface treatment for aluminum sheets. It entails applying a layer of paint to enhance appearance and provide additional protection against corrosion and wear. Painted aluminum sheets are commonly seen in signage, building facades, and decorative applications. Powder coating is a type of surface treatment where a dry powder is applied to the aluminum sheet and then heated to create a protective layer. This treatment offers excellent durability, resistance to weathering, and a wide range of color options. Powder coated aluminum sheets find extensive use in the construction industry, as well as for automotive parts and appliances. Polishing involves buffing the aluminum sheet to create a smooth and reflective surface. This treatment enhances the aesthetics, making it perfect for decorative applications like furniture, jewelry, and architectural accents. In summary, the selection of surface treatment for aluminum sheets depends on desired appearance, functionality, and application requirements. Each treatment provides distinct advantages and characteristics, allowing for versatility and customization in various industries.

- Q: Can the aluminum sheets be used for manufacturing food storage containers?

- Yes, aluminum sheets can be used for manufacturing food storage containers. Aluminum is a popular choice for food storage containers because it is lightweight, durable, and has excellent thermal conductivity. It can easily be formed into various shapes and sizes, making it suitable for different types of food storage needs. Additionally, aluminum is resistant to corrosion and can be easily cleaned, ensuring the safety and hygiene of the stored food.

- Q: How do aluminum sheets perform in terms of formability?

- Aluminum sheets are highly formable due to their low density and high malleability. They can be easily shaped into various forms and are commonly used in industries such as automotive, aerospace, and construction for their excellent formability properties.

- Q: Can aluminum sheets be used for heat sinks in LED lighting?

- Yes, aluminum sheets can be used for heat sinks in LED lighting. Aluminum is widely used in heat sink applications due to its excellent thermal conductivity and lightweight properties. It effectively dissipates heat generated by the LED, helping to maintain optimal operating temperatures and prolong the lifespan of the lighting system.

Send your message to us

Aluminum Diamond Plate Sheets 4x8 - Orange Peel Pattern Aluminum Sheet Coil Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords