1 8 Aluminum Diamond Plate 4 X8

1 8 Aluminum Diamond Plate 4 X8 Related Searches

4x8 1 8 Aluminum Diamond Plate 4x8 Aluminum Diamond Plate 1 8 4 X 8 Aluminum Diamond Plate Aluminum Diamond Plate 4x8 4x8 1 4 Aluminum Diamond Plate 4 X 8 Diamond Plate Aluminum 4x8 Aluminum Diamond Plate 4x8 1/8 Aluminum Diamond Plate 4 8 Aluminum Diamond Plate 4x8 1/8 Diamond Plate Aluminum 4x8 Aluminum Diamond Plate 1/8 Diamond Plate Aluminum 4x8 4x8 Diamond Plate Aluminum 1/4 Aluminum Diamond Plate 4x8 1/8 Aluminum Diamond Plate 4'X8' 4x8 1/4 Aluminum Diamond Plate 4x8 1/4 Diamond Plate Aluminum 1 8 Aluminum Diamond Plate 4 By 8 Aluminum Diamond Plate Black Aluminum Diamond Plate 4x8 1 4 Aluminum Plate 4x8 4x8 Sheet Aluminum Diamond Plate 4x8 Sheet Diamond Plate Aluminum 1 8 Inch Aluminum Diamond Plate 4x8 3 16 Aluminum Diamond Plate Aluminum Diamond Plate 4x8 Sheet 1 8 Inch Diamond Plate Aluminum Aluminum Plate 4x8 Aluminum Diamond Plate 4x8 125 4x8 Aluminum Diamond Plate Price1 8 Aluminum Diamond Plate 4 X8 Supplier & Manufacturer from China

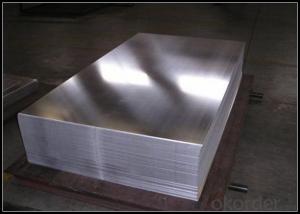

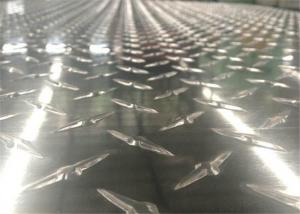

The 1/8 Aluminum Diamond Plate 4x8 is a lightweight and durable metal sheet with a diamond pattern that provides excellent traction and slip resistance. This product is made from high-quality aluminum, ensuring its strength and longevity in various applications. The 1/8" thickness and 4x8 size make it versatile and suitable for a wide range of uses.The 1/8 Aluminum Diamond Plate 4x8 is commonly used in industrial settings, such as walkways, ramps, and platforms, where slip resistance and durability are essential. It is also popular in commercial applications, like loading docks and stair treads, where safety and ease of maintenance are crucial. Additionally, this product can be utilized in residential settings, such as garage floors and patios, to enhance the aesthetic appeal and functionality of the space.

Okorder.com is a reputable wholesale supplier of the 1/8 Aluminum Diamond Plate 4x8, offering a vast inventory to cater to the needs of various customers. With their extensive stock and competitive pricing, Okorder.com is the go-to source for businesses and individuals seeking high-quality aluminum diamond plate at affordable rates.

Hot Products