1.5mm 4X8 Hard Stainless Steel Sheets 201

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

304 St 304 Stainless Steel Sheet ainless Steel Sheet MetalLow Price 2B 1.5mm 4X8 Hard Stainless Steel Sheets 201

Product Description

![]()

Material | 201 304 410 409 430 |

Technology | Cold Rolled |

Thickness | 0.12 mm~2.0mm (tolerances ±0.02 mm) |

Width | 10.0 mm ~1240 mm (tolerances ±0.02 mm) |

Processing | Pickling / Straighten / Flatten / Leveling |

Form | Rolling Coils / Cutting Sheets / Stamping Circles |

Edge | Mill Edge / Slitting Edge |

Annealed | Full hardness to Deep drawing quality (DDQ) |

Surface | BA - processed with bright heat treatment after cold rolling. |

2B - after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | |

2D – matt finish, best choice for deep drawing | |

Protection | 1. Inter paper available |

2. PVC protecting film available | |

All standard products are supplied without inter paper & PVC film. If needed, please inform. | |

Chemical and Mechanical Properties:

GRADE | C | Mn | Si | P | S | Cr | Ni | Cu | T.S. Mpa/min | P.S. Mpa/min | Elongation (%) |

304 | 0.04-0.06 | 1.0-1.2 | 0.25-0.45 | ≤0.40 | 18.1~18.5 | 8~8.2 | ≤0.50 | ||||

409L | ≤0.08 | ≤1 | ≤1 | ≤0.05 | ≤0.03 | 10.5-11.75 | - | 380 | 205 | 22 | |

410 | ≤0.15 | ≤1 | ≤1 | ≤0.04 | ≤0.03 | 11.5-13.5 | ≤0.75 | - | 440 | 205 | 20 |

430 | ≤0.12 | ≤1 | ≤0.75 | ≤0.04 | ≤0.03 | 16-18 | ≤0.75 | - | 450 | 205 | 22 |

201 High Cu | ≤0.15 | 5.5-7.5 | ≤0.75 | ≤0.06 | ≤0.03 | 13.5-15.0 | 1.2-1.5 | 1.4-1.5 | 520 | 275 | 55 |

201 Half Cu | ≤0.15 | 5.5-7.5 | ≤0.75 | ≤0.06 | ≤0.03 | 13.5-15.0 | 1.2-1.5 | 0.8-1.0 | 520 | 275 | 55 |

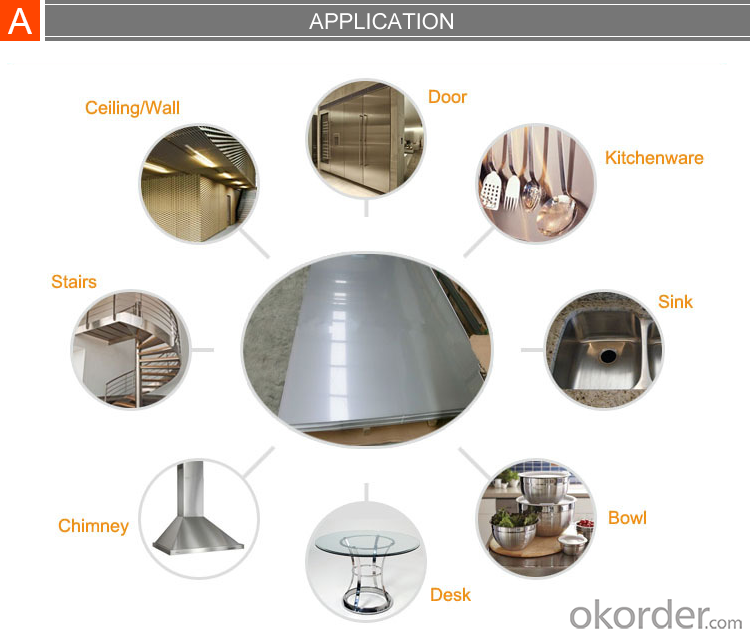

- Q: Can stainless steel sheets be used for wall cladding?

- Yes, stainless steel sheets can be used for wall cladding. Stainless steel is a durable and long-lasting material that is resistant to corrosion, making it a suitable choice for cladding applications. It provides a sleek and modern appearance, adding an aesthetic appeal to the walls. Stainless steel sheets can be easily installed and maintained, making them an excellent option for both interior and exterior walls. Additionally, stainless steel sheets offer excellent fire resistance and can withstand high temperatures, making them a safe choice for wall cladding.

- Q: 904L stainless steel plate generally used in what industry is more?

- Super austenitic stainless steel (904L stainless steel) is a highly alloyed austenitic stainless steel carbon content is very low, in dilute sulphuric acid has good corrosion resistance for corrosion in harsh environmental conditions and design.

- Q: What is the maximum operating temperature for stainless steel sheets?

- The maximum operating temperature for stainless steel sheets typically ranges from 1500°F to 1650°F (815°C to 900°C), depending on the grade of stainless steel.

- Q: Are stainless steel sheets suitable for architectural column covers or cladding?

- Yes, stainless steel sheets are suitable for architectural column covers or cladding. Stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, making it an excellent choice for exterior applications. It can withstand harsh weather conditions, maintain its appearance over time, and provide a sleek and modern look to architectural structures. Additionally, stainless steel sheets offer versatility in terms of finishes, patterns, and colors, allowing architects and designers to create unique and visually appealing column covers or cladding designs.

- Q: Can stainless steel sheets be etched with designs?

- Yes, stainless steel sheets can be etched with designs.

- Q: What is the difference between stainless steel sheets and regular steel sheets?

- The main difference between stainless steel sheets and regular steel sheets is that stainless steel is an alloy that contains a minimum of 10.5% chromium, which gives it its unique corrosion-resistant properties. Regular steel, on the other hand, does not contain enough chromium to be considered stainless and is more prone to rust and corrosion. Stainless steel sheets are also typically more expensive than regular steel sheets due to their enhanced durability and resistance to corrosion.

- Q: How do you prevent scratches or dents on stainless steel sheets?

- To prevent scratches or dents on stainless steel sheets, there are a few measures you can take: 1. Handle with care: When handling stainless steel sheets, be cautious to avoid dropping or dragging them against rough surfaces. Use gloves or protective gear to minimize the risk of scratches caused by sharp objects or tools. 2. Clean with soft materials: To prevent scratches during cleaning, use soft cloths or non-abrasive sponges. Avoid using steel wool or harsh cleaning agents that can damage the surface. Additionally, always wipe in the direction of the grain to maintain the stainless steel's appearance. 3. Use protective films or sheets: Applying a protective film or sheet to the stainless steel surface can provide an extra barrier against scratches or dents. These films are typically adhesive and can be easily removed once the stainless steel sheets are installed. 4. Store properly: Store stainless steel sheets in a clean and dry environment to prevent scratches or dents caused by contact with other objects. Avoid stacking sheets directly on top of each other without any protective barrier in between. 5. Invest in edge protectors: Stainless steel sheets are often susceptible to dents or scratches on their edges. Using edge protectors or corner guards can help prevent damage during handling, transportation, or storage. By following these preventive measures, you can significantly reduce the chances of scratches or dents on stainless steel sheets, ensuring their longevity and maintaining their pristine appearance.

- Q: Can stainless steel sheets be used for chemical reactors?

- Yes, stainless steel sheets can be used for chemical reactors. Stainless steel is highly resistant to corrosion, making it suitable for handling various chemicals and reactive substances. Additionally, it offers excellent heat resistance and durability, making it a popular choice for constructing chemical reactors in industries such as pharmaceuticals, petrochemicals, and food processing.

- Q: Are stainless steel sheets scratch resistant?

- Yes, stainless steel sheets are generally scratch resistant due to their composition and protective layer that helps prevent scratches from everyday use. However, it is important to note that excessive force or abrasive materials can still cause scratches on stainless steel surfaces.

- Q: What is the weight of stainless steel sheets?

- The weight of stainless steel sheets can vary depending on their thickness and dimensions. Generally, stainless steel sheets have a density of 8 grams per cubic centimeter. To calculate the weight of a stainless steel sheet, you would need to know the dimensions (length, width, and thickness) and multiply them together to find the volume. Then, you can multiply the volume by the density to find the weight.

Send your message to us

1.5mm 4X8 Hard Stainless Steel Sheets 201

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords