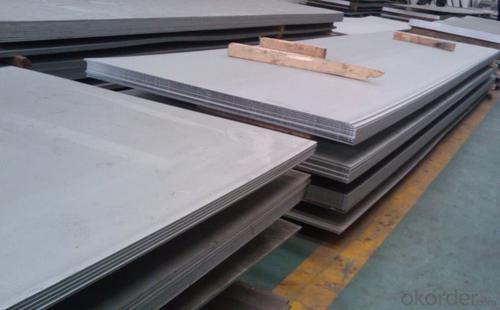

Stainless Steel Sheet and plate 304 Price per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

Product Description

Stainless steel sheet Detailed introduction

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: How do you prevent crevice corrosion in stainless steel sheets?

- To prevent crevice corrosion in stainless steel sheets, several key steps can be taken: 1. Design and fabricate properly: Ensure that the stainless steel sheets have smooth surfaces and minimal crevices during the design and fabrication process. This will decrease the likelihood of trapping stagnant solutions and minimize the possibility of crevice corrosion. 2. Regularly clean and maintain: Clean the stainless steel sheets on a regular basis to eliminate any debris or contaminants that may contribute to crevice corrosion. Mild detergents or specialized stainless steel cleaners can be used for this purpose. 3. Avoid exposure to corrosive environments: Limit the stainless steel sheets' exposure to corrosive surroundings, such as those containing chloride ions (e.g., saltwater). If exposure cannot be avoided, consider applying protective coatings or using higher-grade stainless steel alloys that are more resistant to crevice corrosion. 4. Environmental control: Maintain proper environmental conditions, including temperature, humidity, and pH levels, to minimize the risk of crevice corrosion. Monitoring and controlling these factors can create a less favorable environment for corrosion to occur. 5. Regular inspection and maintenance: Conduct routine inspections to identify any signs of crevice corrosion, such as discoloration, pitting, or rough surfaces. If any corrosion is detected, take immediate action to remove it and repair the affected area. By implementing these preventive measures, the risk of crevice corrosion in stainless steel sheets can be significantly reduced, ensuring their durability and performance.

- Q: How do you bend stainless steel sheets?

- Bending stainless steel sheets typically requires the use of specialized equipment such as a press brake or roller. The sheet is clamped between the tooling and then gradually bent to the desired shape. The process requires precise calculations, proper tooling, and adequate knowledge of the material's properties to avoid any damage or deformation.

- Q: 304 stainless steel plate surface quality inspection method which has several?

- Attachment of cold processing such as workpiece surface lubrication oil, must be fully skimmed in trichloroethylene degreasing agent, caustic soda solution and then with warm water washing, and then heat treatment. Stainless steel plate, if the surface of debris, especially organic matter or ash attached to the workpiece, heating, of course, will have an impact on the oxide skin. Stainless steel plate furnace atmosphere difference, furnace atmosphere in each part of the different, the formation of oxide skin will change, and this is also caused by uneven acid cleaning reasons. Therefore, when heating, the atmosphere in each part of the furnace must be the same. For this reason, the cycle of atmosphere must also be taken into account. Also, a heating workpiece with bench brick, asbestos, if contain water, when heated, water will evaporate, differences in direct contact with the water vapor and other parts of the atmosphere will produce, the formation of oxide of course is different. Therefore, objects that are in direct contact with the heating workpiece must be thoroughly dried before use. However, after drying, such as placed at room temperature, moisture in high conditions, the water will still condense on the surface of the workpiece. So, it's better to dry before use. If the local processing of stainless steel plate before heat treatment with oxide remaining, after heating with oxide remaining parts and parts without oxide, differences in composition and thickness of oxide skin will appear on the surface after pickling caused by uneven, so we should not only pay attention to the final heat treatment, but also to the full note that the middle heat treatment and pickling. There is a difference between the surface of stainless steel and the place where it is not touched.

- Q: Can stainless steel sheets be used for cladding?

- Indeed, cladding can utilize stainless steel sheets. The preference for stainless steel as a cladding material stems from its robustness, ability to withstand corrosion, and visual allure. It is frequently employed in the external cladding of structures, including facades, canopies, and curtain walls. Stainless steel sheets provide an elegant and contemporary look while furnishing defense against severe environmental circumstances. Furthermore, stainless steel cladding necessitates minimal upkeep, boasts an extended lifespan, and can be effortlessly cleaned, rendering it a pragmatic selection for both residential and commercial purposes.

- Q: What is the fatigue strength of stainless steel sheets?

- The fatigue strength of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, surface finish, thickness, and any surface treatments or coatings applied. It is typically higher than that of carbon steel, making stainless steel sheets more resistant to fatigue failure under cyclic loading. However, the exact fatigue strength value will vary and can be determined through testing and analysis specific to the particular stainless steel sheet being used.

- Q: Comparison of three properties of aluminium plate, stainless steel plate and cold rolled plate?

- Aluminum sheet material is light, easy to shape, good coloring;

- Q: What factors affect the cost of stainless steel sheets?

- There are several factors that can affect the cost of stainless steel sheets. These include the type and grade of stainless steel, the thickness and size of the sheets, the quantity being purchased, market demand and availability, production and labor costs, and any additional processing or finishing requirements.

- Q: Are stainless steel sheets resistant to scratches?

- Yes, stainless steel sheets are generally resistant to scratches. Stainless steel is known for its durability and strength, making it highly resistant to scratching or denting. However, it's important to note that no material is completely scratch-proof, and stainless steel can still develop minor scratches over time with regular use. However, these scratches are usually superficial and can often be easily removed or minimized with proper cleaning and maintenance. Additionally, the level of scratch resistance can vary depending on the grade and finish of the stainless steel sheet.

- Q: Can stainless steel sheets be used for storage racks?

- Yes, stainless steel sheets can be used for storage racks. Stainless steel is a durable and corrosion-resistant material, making it suitable for storing various items. It also has a high load-bearing capacity, making it ideal for heavy-duty storage applications.

- Q: How do you determine the best grade of stainless steel sheet for a specific application?

- To determine the best grade of stainless steel sheet for a specific application, several factors need to be considered. These factors include the intended use and environment, corrosion resistance requirements, strength and durability needed, temperature range, and cost constraints. It is essential to consult with experts or engineers knowledgeable in stainless steel grades and their properties to ensure the selection aligns with the specific application's requirements and offers the best balance between performance and cost.

Send your message to us

Stainless Steel Sheet and plate 304 Price per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords