Stainless steel sheet standard Size #4 Polish Treatments

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

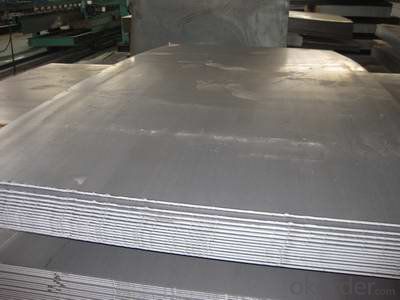

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

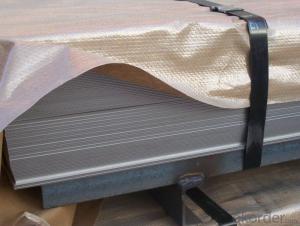

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

What are we supplying now?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What is the elongation of stainless steel sheets?

- The elongation of stainless steel sheets refers to the ability of the material to stretch or deform under tension before breaking. It is typically expressed as a percentage and represents the maximum strain the steel can undergo without fracturing.

- Q: What are the different types of surface protection available for stainless steel sheets?

- There are various options available for protecting stainless steel sheets from corrosion, scratches, and other damage. Each option offers different levels of protection and can be chosen based on specific needs. One commonly used method is the application of a thin, adhesive film onto the stainless steel surface. This film acts as a barrier, safeguarding the sheet from scratches, dirt, and other contaminants. Typically, this film is removed after the sheet is installed. Another popular option is PVC coating, which involves applying a thicker and more durable layer of polyvinyl chloride onto the stainless steel. This coating provides excellent corrosion resistance and is available in different colors and finishes. It can be applied through a process called powder coating. Alternatively, a layer of paint can be applied to the stainless steel surface through spray painting or electrostatic coating methods. Paint coatings not only protect against corrosion but also enhance the appearance of the sheet. Passivation is a chemical process that removes iron from the stainless steel surface, creating a protective oxide layer. This layer improves the sheet's resistance to corrosion and is commonly used in industries with aggressive environments. Electropolishing is a process that removes a thin layer of metal from the stainless steel surface, resulting in a smooth and clean finish. It not only enhances the appearance but also increases the sheet's corrosion resistance. Metal plating involves applying a thin layer of another metal, such as zinc or nickel, onto the stainless steel surface. This provides sacrificial protection, as the plated metal corrodes instead of the underlying stainless steel. Metal plating is commonly used in outdoor applications exposed to harsh environments. When selecting the appropriate surface protection method, it is crucial to consider factors such as the environment, intended use, and aesthetic preferences. These factors will help determine the most suitable option for protecting the stainless steel sheet.

- Q: What's the difference between 304 stainless steel and 314?

- 304 stainless steel is a universal stainless steel material: 314 stainless steel; high temperature oxidation resistance and strong mechanical properties; high heat resistant stainless steel, and 314 austenitic stainless steel, high temperature oxidation resistance and creep resistance. 314 stainless steel used in furnace tube difference

- Q: What are the common applications for stainless steel sheets?

- Stainless steel sheets are commonly used in a variety of applications due to their durability, corrosion resistance, and aesthetic appeal. Some common applications include kitchen appliances, automotive parts, construction materials, medical equipment, and industrial machinery.

- Q: Can stainless steel sheets be used in architectural applications?

- Architectural applications can indeed utilize stainless steel sheets. Stainless steel possesses immense versatility and boasts exceptional strength, durability, and resistance against corrosion, thus rendering it suitable for a vast array of architectural endeavors. It finds common application in cladding, roofing, and facade projects, while also serving as a building's structural backbone in the form of columns and beams. The malleability of stainless steel sheets allows architects to fashion them into diverse shapes and sizes, enabling the realization of unique designs and visually captivating structures. Additionally, stainless steel's sleek and contemporary appearance contributes to its allure in modern architecture. In summary, stainless steel sheets remain a favored choice in architectural applications due to their practicality, resilience, and aesthetic attributes.

- Q: Can stainless steel sheets be used for desalination plants?

- Yes, stainless steel sheets can be used for desalination plants. Stainless steel is highly resistant to corrosion, which makes it an ideal material for desalination plants where saltwater is being processed. The durability and longevity of stainless steel sheets also make them suitable for withstanding the harsh conditions and high pressures involved in the desalination process.

- Q: What is the electrical resistance of stainless steel sheets?

- The electrical resistance of stainless steel sheets can vary depending on factors such as the grade of stainless steel, its thickness, and the temperature at which it is being used. However, in general, stainless steel is considered to have a relatively high electrical resistance compared to other metals.

- Q: Are stainless steel sheets suitable for high-temperature applications?

- Stainless steel sheets are well-suited for high-temperature applications. Renowned for their outstanding heat resistance properties, stainless steel proves to be an optimal material for utilization in environments with elevated temperatures. It possesses the ability to endure extreme heat while retaining its strength and structural integrity, rendering it exceptionally resilient and dependable. Industries such as aerospace, automotive, and manufacturing frequently employ stainless steel sheets, as they commonly encounter high temperatures. Furthermore, stainless steel sheets exhibit minimal thermal expansion, ensuring that their shape and dimensions remain intact even when exposed to varying temperatures. Consequently, stainless steel sheets are the preferred choice for applications in which dimensional stability is of utmost importance. All in all, stainless steel sheets are an appropriate alternative for high-temperature applications due to their exceptional heat resistance, durability, and dimensional stability.

- Q: How do stainless steel sheets compare to other materials, such as aluminum or carbon steel?

- Stainless steel sheets possess several advantages when compared to materials like aluminum or carbon steel. Their corrosion resistance stands as one of the main benefits. By containing chromium, stainless steel forms a passive film on its surface, guarding it against rust and other forms of corrosion. As a result, stainless steel sheets prove ideal for outdoor and marine applications, where exposure to moisture and corrosive elements is common. In terms of strength, stainless steel sheets generally surpass aluminum but fall short of carbon steel. Nevertheless, through heat treatment, stainless steel sheets can be hardened, increasing their strength and durability. This characteristic renders them suitable for applications that demand high strength and resistance to wear and tear. Stainless steel sheets also exhibit remarkable heat resistance. They can withstand high temperatures without compromising their structural integrity, making them appropriate for use in industries such as food processing, chemicals, and petrochemicals. Another advantage of stainless steel sheets lies in their aesthetic appeal. With their sleek and modern appearance, they complement various design styles. Architects and interior designers frequently include stainless steel sheets in their projects, particularly when visual appeal holds significance. However, despite the numerous advantages, it is important to consider certain factors when working with stainless steel sheets. Stainless steel can be more expensive than aluminum or carbon steel, particularly for high-grade alloys. Additionally, its higher strength and hardness may pose challenges during shaping and machining. Specialized tools and techniques may be necessary when working with stainless steel sheets. In conclusion, stainless steel sheets offer a unique combination of corrosion resistance, strength, heat resistance, and aesthetic appeal. Depending on the specific requirements of a project, stainless steel may be the preferred choice over materials like aluminum or carbon steel.

- Q: Are stainless steel plates 3.4mm or 3.5mm thick?

- The thickness of less than 30mm of any size 0.5mm ratio, thickness more than 30mm of any size 1mm times.

Send your message to us

Stainless steel sheet standard Size #4 Polish Treatments

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords