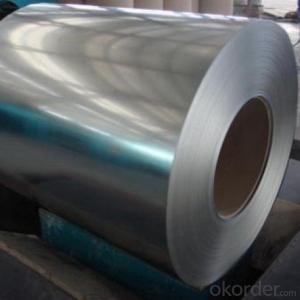

Stainless Steel Coil 304

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coil 304

1.Thickness:0.4mm-80mm

2. Width:1000mm-1500mm

3. Price:1000USD-4500USD

Size(in mm) | 1000*2000,1220*2440,1250*2500,1500*3000,1500*6000 Or as customer’s requirement |

Thickness(mm) | 0.4-80 |

Specification | A240 |

Grade | 430,409,420,201,202,304,304L,316L,310S, 309and so on |

Certificate | Manufacturer Test Certificate, Laboratory Test Certificate |

Standard | ASTM,GB,JIS, |

Surface | 2B,BA,Mirror,Hair Line,No.4+PVC |

Technique | Cold rolled and hot rolled |

MOQ | 1 ton |

Supply Ability | 1000 tons/month |

Terms of payment | TT or LC |

- Q: Are stainless steel sheets heat resistant?

- Yes, stainless steel sheets are heat resistant. Stainless steel is known for its high resistance to heat and corrosion, making it suitable for various applications that involve high temperatures. It can withstand high levels of heat without warping, melting, or losing its structural integrity. This heat resistance is due to the chromium content in stainless steel, which forms a protective oxide layer on the surface, preventing oxidation and maintaining its strength even at elevated temperatures. As a result, stainless steel sheets are commonly used in industries such as manufacturing, construction, automotive, and food processing, where heat resistance is crucial.

- Q: How do you prevent intergranular corrosion on stainless steel sheets?

- Intergranular corrosion is a type of corrosion that occurs along the grain boundaries of stainless steel, leading to structural damage and reduced strength. To prevent intergranular corrosion on stainless steel sheets, several measures can be taken: 1. Material Selection: Choosing the right grade of stainless steel is crucial in preventing intergranular corrosion. Grades with low carbon content, such as 304L or 316L, are less prone to this type of corrosion due to their reduced susceptibility to sensitization. 2. Heat Treatment: Stainless steel sheets can be heat treated to remove carbide precipitation, a common cause of intergranular corrosion. The process, known as solution annealing or sensitization heat treatment, involves heating the material to a specific temperature range and then rapidly cooling it. This treatment ensures the formation of a consistent and corrosion-resistant microstructure. 3. Passivation: Passivation is a chemical process that removes contaminants and forms a protective oxide layer on the surface of stainless steel sheets. This layer acts as a barrier against corrosion and prevents intergranular attack. Passivation is typically done using nitric acid or citric acid solutions. 4. Welding Techniques: When welding stainless steel sheets, it is important to use proper welding techniques to minimize the risk of intergranular corrosion. This includes using low heat input, avoiding excessive heat build-up, and employing filler materials with low carbon content to prevent sensitization. 5. Avoiding Contamination: Stainless steel sheets should be protected from contamination by other metals, especially those with higher galvanic potentials. Contact with carbon steel, for example, can result in galvanic corrosion and promote intergranular attack. Therefore, it is essential to separate stainless steel sheets from other metals in storage and during fabrication. 6. Regular Cleaning and Maintenance: Regular cleaning and maintenance of stainless steel sheets are essential to prevent the accumulation of corrosive substances or contaminants on the surface. Proper cleaning methods and non-abrasive cleaners should be used to avoid scratching the stainless steel, which can create sites for corrosion initiation. By implementing these preventive measures, intergranular corrosion can be significantly minimized, ensuring the longevity and performance of stainless steel sheets.

- Q: What is the average lifespan of stainless steel sheets?

- The average lifespan of stainless steel sheets can vary depending on various factors such as the grade and quality of the stainless steel, the environment in which it is used, and the level of maintenance and care it receives. Generally, stainless steel sheets are known for their durability and longevity. They are designed to resist corrosion, rust, and other forms of degradation, making them suitable for a wide range of applications. In ideal conditions and with proper maintenance, stainless steel sheets can last for several decades or even longer. However, in more aggressive environments with exposure to harsh chemicals, extreme temperatures, or high levels of moisture, the lifespan of stainless steel sheets may be reduced. Regular cleaning, proper storage, and routine inspections are important to ensure the longevity of stainless steel sheets. By following recommended maintenance practices, stainless steel sheets can provide reliable performance and a long lifespan.

- Q: Can stainless steel sheets be used for cladding?

- Indeed, cladding can utilize stainless steel sheets. The preference for stainless steel as a cladding material stems from its robustness, ability to withstand corrosion, and visual allure. It is frequently employed in the external cladding of structures, including facades, canopies, and curtain walls. Stainless steel sheets provide an elegant and contemporary look while furnishing defense against severe environmental circumstances. Furthermore, stainless steel cladding necessitates minimal upkeep, boasts an extended lifespan, and can be effortlessly cleaned, rendering it a pragmatic selection for both residential and commercial purposes.

- Q: What are the different types of stainless steel sheet finishes available?

- Some common types of stainless steel sheet finishes include brushed, mirror, satin, and patterned finishes.

- Q: What is the electrical resistance of stainless steel sheets?

- The electrical resistance of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, its thickness, and the specific properties of the alloy used. Generally, stainless steel is known to have a relatively high electrical resistance compared to other metals. This is due to its composition, which includes a significant amount of chromium and other alloying elements that hinder the flow of electric current. However, the exact value of electrical resistance can range from a few micro-ohms per square meter to several ohms per square meter, depending on the specific grade and thickness of the stainless steel sheet. Therefore, it is crucial to consult the manufacturer's specifications or conduct specific electrical resistance tests to obtain accurate values for a particular stainless steel sheet.

- Q: Can stainless steel sheets be used in manufacturing processes?

- Yes, stainless steel sheets can be used in manufacturing processes. Stainless steel is a highly versatile and durable material that is commonly used in various industrial applications. Due to its corrosion resistance, strength, and heat resistance properties, stainless steel sheets are ideal for manufacturing processes that require a material to withstand harsh conditions, such as chemical processing, food and beverage production, pharmaceutical manufacturing, and automotive manufacturing. Stainless steel sheets can be formed, cut, welded, and machined to suit specific manufacturing requirements, making them a popular choice in the industry.

- Q: Are stainless steel sheets suitable for elevator doors?

- Yes, stainless steel sheets are suitable for elevator doors. Stainless steel is a durable and corrosion-resistant material that can withstand the wear and tear associated with elevator use. It also offers a sleek and modern appearance, making it a popular choice for elevator doors in various settings.

- Q: Can stainless steel sheets be used for cryogenic storage containers?

- Indeed, cryogenic storage containers can make use of stainless steel sheets. Stainless steel is renowned for its exceptional strength, durability, and corrosion resistance, making it perfectly suitable for cryogenic purposes. Moreover, stainless steel exhibits low thermal conductivity, effectively reducing heat transfer from the environment to the stored contents. This particular characteristic is vital in cryogenic storage as it helps maintain the necessary low temperatures for preserving materials like liquefied gases or biological samples. In summary, stainless steel sheets serve as a dependable and widely employed material for cryogenic storage containers.

- Q: What are the different types of patterned finishes available for stainless steel sheets?

- There are several types of patterned finishes available for stainless steel sheets, including embossed, textured, perforated, brushed, and hammered finishes. Each of these finishes offers a unique aesthetic appeal and texture to the stainless steel, allowing for versatile applications in various industries such as architecture, interior design, and automotive.

Send your message to us

Stainless Steel Coil 304

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords