Stainless Steel Sheet Metal Fabrication

Stainless Steel Sheet Metal Fabrication Related Searches

Stainless Steel Sheeting Stainless Steel Fabrications Sheet Of Stainless Steel Stainless Steel Sheetmetal Black Stainless Steel Sheet Stainless Steel Shelving Stainless Steel Shelves Stainless Steel Sheet Prices Stainless Steel 3d Printing Stainless Steel Sheet Price Stainless Steel Factory Stainless Steel Sheets For Sale Stainless Steel Sheets Price Thin Stainless Steel Sheets Stainless Steel Material 3d Printing Stainless Steel Stainless Steel Manufacturer Stainless Steel Mesh Stainless Steel Molding Stainless Steel Structure Stainless Steel Metals Stainless Steel Stamping Stainless Steel Materials Stainless Steel Hardware Stainless Steel Supply Thin Sheet Stainless Steel Stainless Steel Wrapping Stainless Steel Refrigeration Stainless Steel Plant Stainless Steel Made OfStainless Steel Sheet Metal Fabrication Supplier & Manufacturer from China

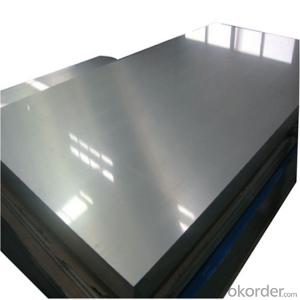

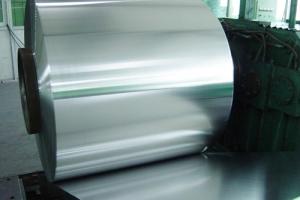

Stainless Steel Sheet Metal Fabrication encompasses a wide range of products, including sheets, plates, and various custom-made components. These products are made from high-quality stainless steel materials, which offer excellent corrosion resistance, strength, and durability. They are widely used in various industries due to their versatility and long-lasting performance.Stainless Steel Sheet Metal Fabrication products find their applications in numerous scenarios, such as in the construction of architectural structures, manufacturing of industrial equipment, and the creation of kitchen appliances. Their resistance to corrosion and ability to withstand harsh conditions make them ideal for both indoor and outdoor use. They can be easily shaped and formed into various designs, making them a popular choice for architects and engineers alike.

Okorder.com is a leading wholesale supplier of Stainless Steel Sheet Metal Fabrication products. With a large inventory and a commitment to providing high-quality materials, they cater to the needs of businesses and individuals alike. Their extensive range of products ensures that customers can find the perfect stainless steel solution for their specific requirements, making Okorder.com a trusted source for all things related to stainless steel fabrication.

Hot Products