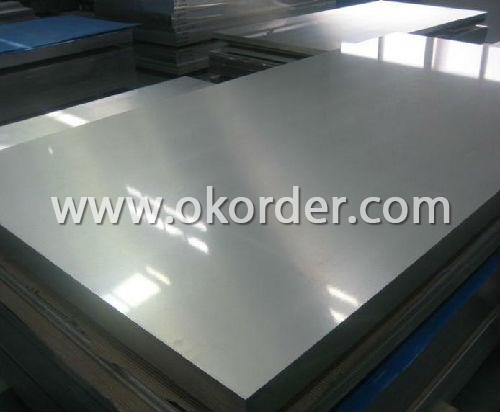

AISI 304 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 304 Stainless Steel Sheet

1. Chemical composition of AISI 304 Stainless Steel Sheet

C | Si | Mn | P | S | Ni | Cr |

max0.08 | max1.00 | max2.00 | max0.045 | max0.03 | 8.00-10.50 | 18.00-20.00 |

2. Mechanical properties of AISI 304 Stainless Steel Sheet

Yield Strength | Tensile | Elongation | Hardness (HV) | Hardness (HRB) |

≥ 205 | ≥ 520 | ≥ 40 | ≤ 200 | ≤ 90 |

3. Standard of AISI 304 Stainless Steel Sheet : AISI, ASTM, GB, EN, DIN, JIS

4. Surface of AISI 304 Stainless Steel Sheet : 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size of AISI 304 Stainless Steel Sheet :

Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ of AISI 304 Stainless Steel Sheet : 1 Ton

7. Payment terms of AISI 304 Stainless Steel Sheet : T/T or L/C

8. Packing of AISI 304 Stainless Steel Sheet : Seaworthy package with wooden or Iron pallets with the paper and the steel strip,

or as customers' request.

9. Delivery time of AISI 304 Stainless Steel Sheet : Usually about 7 days after we confirming the order, or according to your quantity.

If you have any demand, pls feel free to contact me.

- Q:Can stainless steel strips be used in the electronics manufacturing industry?

- Certainly, the electronics manufacturing industry does utilize stainless steel strips. Renowned for its strength, durability, and resistance to corrosion, stainless steel is a versatile material that is highly suitable for numerous applications within the electronics sector. Electronic components, including connectors, terminals, and shielding, often rely on stainless steel strips for their fabrication. These strips possess the ability to be easily shaped and formed into precise sizes and shapes, facilitating the meticulous manufacturing of intricate electronic parts. Moreover, stainless steel's resistance to corrosion is especially vital in electronic devices that face exposure to harsh environments or moisture. This resistance ensures the components' longevity and reliability, effectively preventing premature failure. Furthermore, stainless steel strips find utility in the production of electronic enclosures, cabinets, and frames. These structures serve to safeguard and support delicate electronic circuitry, effectively shielding it from external factors such as electromagnetic interference or physical damage. In addition to its mechanical properties, stainless steel also boasts excellent thermal conductivity. This attribute proves advantageous within the electronics industry, as it aids in the dissipation of heat generated by electronic devices. Consequently, optimal performance is maintained, and overheating is prevented. In conclusion, due to their strength, durability, corrosion resistance, and thermal conductivity, stainless steel strips hold immense value within the electronics manufacturing industry. They fulfill a crucial role in the production of electronic components, enclosures, and other essential structures, ultimately contributing to the reliability and performance of electronic devices.

- Q:Are stainless steel strips resistant to oxidation?

- Stainless steel strips exhibit resistance to oxidation due to their composition as an alloy containing chromium. When exposed to oxygen in the atmosphere, chromium reacts and creates a protective layer known as chromium oxide on the surface. This layer acts as a barrier, effectively halting any additional oxidation or corrosion of the metal. Consequently, stainless steel strips possess exceptional resistance to both rust and corrosion, rendering them highly suitable for applications involving moisture or challenging surroundings.

- Q:Can 111 stainless steel strips be annealed for improved ductility?

- Indeed, it is possible to anneal a total of 111 stainless steel strips to enhance their ductility. Annealing entails subjecting the material to a precise temperature and subsequently gradually cooling it. This procedure serves to alleviate any internal tensions within the material and facilitates the reorganization of atoms, leading to increased ductility and decreased hardness. Through the annealing process, the stainless steel strips can acquire greater malleability and become more manageable, rendering them suitable for numerous applications that prioritize enhanced ductility.

- Q:Are stainless steel strips suitable for architectural signage?

- Architectural signage can benefit greatly from the use of stainless steel strips. This material is a popular choice due to its durability, aesthetic appeal, and resistance to corrosion. With its versatility, stainless steel can be easily shaped into different sizes and forms to create various types of signage, including letters, logos, and plaques. When it comes to appearance, stainless steel strips offer a sleek and modern look that can complement any architectural design. They can be finished in different ways, such as brushed, polished, or etched, to achieve the desired visual effect. Not only do they look good, but they also provide excellent weather resistance, making them suitable for both indoor and outdoor signage. Apart from its visual qualities, stainless steel is highly durable and can withstand harsh environmental conditions. It is resistant to corrosion, rust, and fading, ensuring that the signage remains visually appealing and readable for a long time. This makes stainless steel strips a reliable choice for architectural signage, especially in areas with high levels of foot traffic or exposure to extreme weather. Another advantage of using stainless steel is its low maintenance requirements. It is easy to clean and maintain, making it a cost-effective choice in the long run. In summary, stainless steel strips are a suitable option for architectural signage due to their durability, aesthetic appeal, resistance to corrosion, and low maintenance requirements. Whether it's for commercial buildings, residential complexes, or public spaces, stainless steel signage can add a touch of sophistication and professionalism to any architectural project.

- Q:Are stainless steel strips suitable for pharmaceutical equipment?

- Yes, stainless steel strips are suitable for pharmaceutical equipment. Stainless steel is a commonly used material in the pharmaceutical industry due to its excellent corrosion resistance, durability, and hygienic properties. It is easy to clean, resistant to bacteria growth, and can withstand high temperatures and harsh chemicals typically used in pharmaceutical processes. Stainless steel strips can be used for various applications in pharmaceutical equipment, including manufacturing vessels, storage tanks, mixing equipment, conveyors, and packaging machinery. The material's strength and reliability make it suitable for maintaining the integrity and cleanliness required in pharmaceutical facilities, ensuring product safety and quality.

- Q:How do you prevent rusting of stainless steel strips?

- There are several measures that can be taken to prevent the rusting of stainless steel strips: 1. It is recommended to clean stainless steel strips regularly using mild soap or detergent and warm water. This will effectively eliminate any dirt, dust, or contaminants that may cause corrosion. 2. It is important to avoid direct contact between stainless steel and corrosive substances like acids, bleach, or saltwater. Any spills should be promptly cleaned to prevent prolonged exposure. 3. Thoroughly drying stainless steel strips after cleaning is crucial to eliminate moisture, as it can promote corrosion. Therefore, ensuring the surface is completely dry is essential. 4. The application of protective coatings, such as clear lacquer or oil-based coatings, can create a barrier between the steel and the environment, reducing the risk of rusting. Regular reapplication of these coatings is necessary to maintain their effectiveness. 5. Proper storage methods are important to prevent rusting. Stainless steel strips should be stored in a clean and dry environment, away from moisture or corrosive substances. Additionally, using padding or separators between strips can prevent scratching, which may lead to rusting. 6. Regularly inspecting stainless steel strips for any signs of corrosion or damage is beneficial in identifying and addressing potential issues early on. Timely action can prevent further rusting and extend the lifespan of the strips. By adhering to these preventive measures, the risk of rusting in stainless steel strips can be significantly reduced, ensuring their longevity and preserving their appearance.

- Q:Can stainless steel strips be used for structural applications?

- Stainless steel strips possess the ability to fulfill structural needs. This is due to stainless steel's exceptional resistance to corrosion, remarkable strength, and enduring nature, which render it suitable for a wide range of structural purposes. In the construction realm, stainless steel strips can be employed in the creation of buildings, bridges, and other infrastructure ventures. Moreover, they find utility in the production of machinery, automotive components, and household appliances. The adaptability of stainless steel strips allows for their manipulation into various shapes and sizes through forming, welding, and other techniques, thus making them an ideal choice for structural uses. Furthermore, the aesthetic appeal and minimal maintenance requirements of stainless steel contribute to its popularity in architectural contexts. In conclusion, stainless steel strips emerge as a trustworthy and efficient material for structural applications.

- Q:Are stainless steel strips easy to form and shape?

- Yes, stainless steel strips are relatively easy to form and shape due to their malleability and ductility. They can be easily bent, rolled, or manipulated into various desired shapes without losing their structural integrity.

- Q:Can stainless steel strips be used in electronic applications?

- Yes, stainless steel strips can be used in electronic applications. Stainless steel has excellent corrosion resistance and mechanical properties, making it suitable for various electronic components and devices. It is commonly used in applications such as connectors, terminals, springs, shields, and enclosures. Stainless steel strips provide high strength and durability, ensuring reliable performance in electronic circuits. Additionally, stainless steel's non-magnetic properties make it ideal for applications that require minimal interference with magnetic fields. Overall, stainless steel strips offer several advantages for electronic applications, making them a popular choice in the industry.

- Q:Can stainless steel strips be used in the petrochemical industry?

- Certainly, the petrochemical industry finds stainless steel strips to be a valuable asset. The exceptional corrosion resistance of stainless steel renders it suitable for a wide range of applications in this sector. Given that petrochemical processes often involve the manipulation of various corrosive chemicals, gases, and liquids, stainless steel strips are frequently employed in the construction of storage tanks, pipelines, heat exchangers, and other necessary equipment. The indispensability of corrosion resistance in these structures cannot be overstated. Moreover, the high strength and durability of stainless steel endow it with the ability to withstand the demanding conditions of the petrochemical industry, including high temperatures and pressures. Consequently, it is safe to conclude that stainless steel strips are the preferred material in the petrochemical sector due to their corrosion resistance, strength, and longevity.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

AISI 304 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords