302 Stainless Steel Sheet

302 Stainless Steel Sheet Related Searches

302 Stainless Steel 316 Stainless Steel Sheet 301 Stainless Steel 300 Stainless Steel 305 Stainless Steel 300 Series Stainless Steel 310 Stainless Steel Sheet Of Stainless Steel 304l Stainless Steel Thin Stainless Steel Sheets Black Stainless Steel Sheet Type 304 Stainless Steel 304 Stainless Steel Pipe Thin Sheet Stainless Steel Stainless Steel 303 304 Grade Stainless Steel Stainless Steel Sheeting Grade 304 Stainless Steel T304 Stainless Steel 1 8 Stainless Steel Sheet 330 Stainless Steel 420 Stainless Steel 304 Stainless Steel Tubing Sus 304 Stainless Steel Stainless Steel 316 Stainless Steel Sheet Price Stainless Steel 420 16 Gauge Stainless Steel Sheet Stainless Steel 316l 20 Gauge Stainless Steel Sheet302 Stainless Steel Sheet Supplier & Manufacturer from China

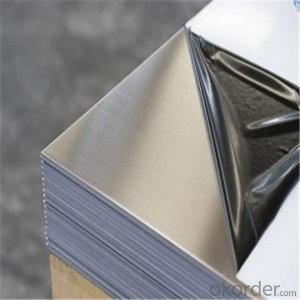

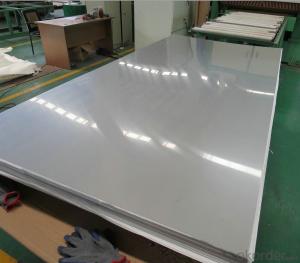

302 Stainless Steel Sheet is a type of austenitic stainless steel, known for its excellent corrosion resistance and formability. This grade of stainless steel is widely recognized for its ability to maintain strength and durability in various environments, making it a popular choice for numerous applications. The product's composition, which includes a higher carbon content than other austenitic grades, contributes to its enhanced strength and hardness, while still maintaining good ductility and weldability.The 302 Stainless Steel Sheet finds its application in a broad range of industries, including automotive, aerospace, and construction. Its ability to resist corrosion and withstand high temperatures makes it ideal for use in components that require both strength and durability. Additionally, its formability allows for the creation of intricate designs and shapes, making it a versatile material for various applications. Whether it's used in the manufacturing of automotive parts, structural components, or decorative elements, 302 Stainless Steel Sheet continues to be a preferred choice for its reliability and performance.

Okorder.com is a reputable wholesale supplier of 302 Stainless Steel Sheet, boasting a large inventory to cater to the diverse needs of clients across different industries. As a leading distributor, Okorder.com ensures that customers have access to high-quality stainless steel sheets at competitive prices. Their extensive inventory guarantees that customers can find the specific grade, size, and thickness of 302 Stainless Steel Sheet they require for their projects. With a commitment to customer satisfaction and a focus on providing top-notch products, Okorder.com stands out as a reliable source for 302 Stainless Steel Sheet.

Hot Products