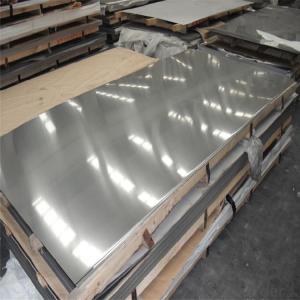

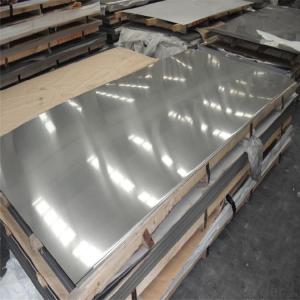

Stainless Steel Coils and Sheets 201 304 316

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications of Stainless Steel Coils and Sheets:

1. Automotive:Automotive trim and molding/Difficult-to-form exhaust-system components, tubular manifolds, mufflers/Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps

2. Construction: Gutters and downspouts, roofing, siding

3. Kitchenware: Cooking utensils, dishwashers, ovens, range hoods, refrigerators, skewers

4. Chemical processing: Oil refinery equipment, oil burner and heater parts

5. Appliances: Hot water tanks, residential furnaces

6. Power generation: Heat Exchanger tubing

7. Farming: Dry fertilizer spreaders/Farm animal pens

Technical notes:

- Q: How to calculate the weight of stainless steel plate?

- There are usually only six kinds of steel related to the application of building construction. They all contain 17 to 22% chromium, and better steel also contains nickel. The addition of molybdenum can further improve atmospheric corrosion, especially for atmospheric corrosion resistant chlorides.

- Q: Can stainless steel sheets be used for decorative wall panels?

- Indeed, decorative wall panels can be crafted using stainless steel sheets. Stainless steel, a highly versatile material, lends itself effortlessly to shaping and manipulation, enabling the creation of numerous designs and patterns. Its sleek and contemporary appearance has made it a favored option for both contemporary and industrial-style interiors. Furthermore, stainless steel sheets come in a variety of finishes, including brushed, mirrored, and textured, offering further customization and enhancing the visual appeal of the wall panels. Moreover, stainless steel boasts resistance to corrosion, durability, and easy maintenance, rendering it suitable for high-traffic areas or environments prone to moisture or humidity. In summary, stainless steel sheets present an elegant and practical solution for decorative wall panels.

- Q: Can stainless steel sheets be used for outdoor furniture or fixtures?

- Outdoor furniture or fixtures can indeed utilize stainless steel sheets. Stainless steel, being a material highly resistant to corrosion and exceptionally durable, makes it perfect for outdoor applications. Its resistance to rust enables it to endure different weather conditions, such as rain, snow, and high humidity. Furthermore, stainless steel possesses a sleek and contemporary look, which contributes to its popularity as a preferred option for outdoor furniture and fixtures. Its strength, longevity, and ability to withstand environmental factors explain why it is frequently employed in constructing outdoor tables, chairs, benches, grills, and other fixtures.

- Q: Can stainless steel sheets be used in automotive industry?

- The automotive industry finds stainless steel sheets to be a valuable resource. This material has gained popularity due to its numerous advantageous properties. Its exceptional resistance to corrosion makes it an ideal choice for components that are exposed to harsh weather conditions, like car exteriors and body panels. Stainless steel sheets are also renowned for their impressive strength-to-weight ratio, enabling the creation of lightweight yet sturdy automobile parts. Moreover, stainless steel exhibits remarkable heat resistance and can endure high temperatures, making it suitable for applications like exhaust systems. In summary, stainless steel sheets are extensively utilized in the automotive industry because of their durability, ability to resist corrosion, and versatility in various applications.

- Q: Are stainless steel sheets good for pressure vessels?

- Stainless steel sheets have gained popularity as a preferred choice for pressure vessels due to their durability, reliability, and ability to meet the demanding requirements of such applications. Commonly employed, they are considered to be an excellent option. Stainless steel possesses exceptional resistance to corrosion, high strength, and commendable mechanical properties, rendering it suitable for applications that necessitate withstanding high pressures. Moreover, stainless steel exhibits remarkable heat resistance, a pivotal trait in pressure vessels where exposure to elevated temperatures is likely. It is also important to highlight that stainless steel lends itself to easy formation and welding, facilitating the fabrication of intricate shapes and designs required for pressure vessel construction. All in all, stainless steel sheets are a favored material for pressure vessels due to their ability to endure, their dependability, and their capacity to fulfill the demanding prerequisites of such applications.

- Q: Can stainless steel sheets be used for kitchen backsplashes?

- Yes, stainless steel sheets can be used for kitchen backsplashes. Stainless steel is a popular choice for kitchen backsplashes due to its durability, resistance to heat and moisture, and easy maintenance. It provides a sleek and modern look to the kitchen while also protecting the wall from splatters and stains. Additionally, stainless steel sheets are available in various finishes, such as brushed, mirrored, or patterned, allowing homeowners to choose the style that best complements their kitchen design.

- Q: Can stainless steel sheets be used for elevator handrails or grab bars?

- Yes, stainless steel sheets can be used for elevator handrails or grab bars. Stainless steel is a popular choice for these applications due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel sheets can be fabricated into various shapes and sizes to meet the specific requirements of elevator handrails or grab bars, ensuring safety and comfort for users. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for high-traffic areas such as elevators.

- Q: What are the different types of brushed finishes available for stainless steel sheets?

- Stainless steel sheets offer a variety of brushed finishes, each with its own distinct appearance and texture. Some of the most commonly used finishes are as follows: 1. The #4 Brushed Finish: This is the go-to choice for many as it provides a smooth, directional grain achieved through the use of a grit belt or wheel. People often refer to this finish as a satin finish. 2. The #6 Brushed Finish: For a more refined appearance, the #6 finish is the way to go. It is achieved by using a higher grit abrasive belt or wheel, resulting in a smoother and more sophisticated look. This finish is often chosen for decorative purposes or when a higher level of elegance is desired. 3. The #8 Mirror Finish: If you're after a glossy, reflective appearance, the #8 finish is the perfect choice. It requires extensive polishing and buffing to achieve a nearly perfect reflective surface. This finish is highly favored in architectural and decorative applications where a polished and glamorous look is desired. 4. The Bead Blasted Finish: To achieve a matte, non-reflective surface, stainless steel sheets are blasted with glass beads under high pressure. This process creates a uniform and textured appearance, making it ideal for applications that require a low-maintenance finish. 5. The Linen Finish: For a visually appealing touch, the linen finish offers a pattern of parallel lines that resemble linen fabric. This finish is achieved by using abrasive belts or wheels with varying grit sizes, resulting in a textured finish. It is commonly used in architectural and interior design applications. These examples represent just a few of the many brushed finishes available for stainless steel sheets. The choice of finish will depend on the desired aesthetic, functionality, and specific application requirements.

- Q: What is the lifespan of stainless steel sheets?

- The durability and lifespan of stainless steel sheets can vary depending on several factors, including the grade of stainless steel, the environmental conditions in which they are used, and the maintenance practices followed. Generally speaking, stainless steel sheets are known for their long lifespan and are highly resistant to corrosion and degradation. They are designed to endure harsh conditions and are resistant to rust, stains, and other forms of damage. Stainless steel sheets are typically manufactured using austenitic stainless steel, which contains high levels of chromium and nickel. These elements contribute to excellent corrosion resistance, making stainless steel sheets highly resistant to rust and staining. Consequently, stainless steel sheets can outlast materials like aluminum or regular steel and remain in good condition for many years. Proper care and maintenance can further prolong the lifespan of stainless steel sheets. Regular cleaning and removal of contaminants or debris help prevent corrosion and maintain the sheets' appearance and performance. Additionally, applying protective coatings or finishes adds an extra layer of defense against corrosion and wear. While providing an exact lifespan for stainless steel sheets is challenging due to the various factors involved, with adequate care and maintenance, they can easily endure for several decades. In some instances, stainless steel sheets have been known to last over a century. Therefore, investing in stainless steel sheets is often considered a long-term solution, offering durability and cost-effectiveness over an extended period of time.

- Q: What are the different shapes available for stainless steel sheets?

- Stainless steel sheets come in various shapes to meet specific requirements and applications. Let's explore some of the most common options: 1. Rectangular sheets: These sheets are widely used and can be easily cut to the desired dimensions. They are available in different standard sizes. 2. Round sheets: Round stainless steel sheets are ideal for decorative purposes or when a seamless or curved surface is desired. They come in various diameters and thicknesses. 3. Square sheets: Similar to rectangular sheets, square stainless steel sheets are versatile and provide a symmetrical and uniform appearance. They can be easily customized to fit specific sizes. 4. Perforated sheets: These sheets have a regular pattern of small holes punched through them. They are commonly used in architectural and industrial applications that require ventilation, filtration, or visibility. 5. Embossed sheets: These sheets feature raised or recessed patterns on their surface, adding texture and visual interest. They find applications in interior design, furniture manufacturing, and automotive industries. 6. Expanded metal sheets: These sheets are created by cutting and stretching a solid stainless steel sheet, resulting in a grid-like pattern with diamond-shaped openings. They are commonly used in security fencing, walkways, and industrial settings. 7. Checker plate sheets: Also known as tread plate or diamond plate, these sheets have a raised diamond pattern on the surface. They are frequently used for slip-resistant flooring, stair treads, and decorative accents. These examples represent just a few of the available stainless steel sheet shapes. The choice of shape depends on the specific requirements, aesthetic preferences, and functional needs of the project.

Send your message to us

Stainless Steel Coils and Sheets 201 304 316

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords