Color Coated Galvanized Steel Coil with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 7000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

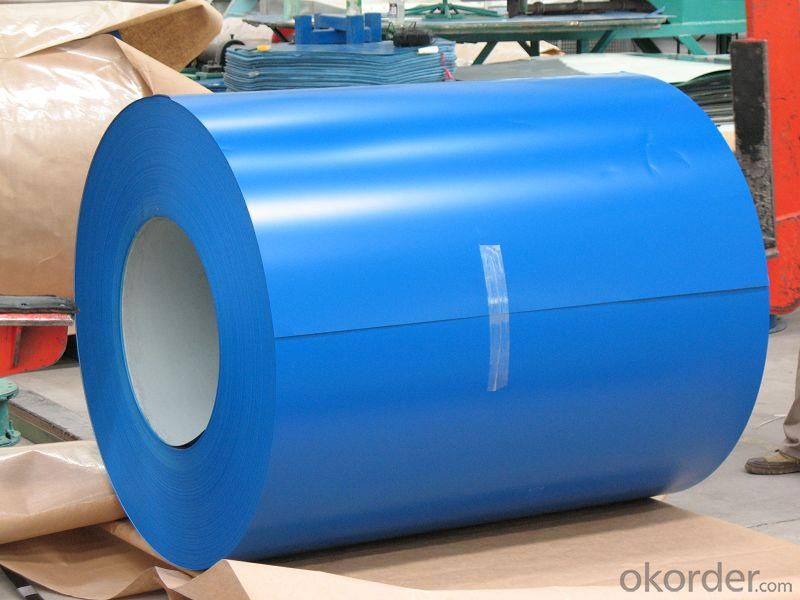

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images:

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification:

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the benefits of using textured stainless steel sheets in decorative lighting fixtures?

- There are several benefits of using textured stainless steel sheets in decorative lighting fixtures. Firstly, textured stainless steel sheets add a unique and visually appealing element to the lighting fixture. The texture creates depth and dimension, making the fixture stand out and become a focal point in any space. Whether it is a hammered, brushed, or embossed texture, it adds a touch of elegance and sophistication to the overall design. Secondly, stainless steel is a durable and long-lasting material. It is resistant to corrosion, rust, and damage caused by moisture or humidity. This makes it an ideal choice for lighting fixtures, especially in outdoor or high-moisture environments. The textured surface also helps to hide any potential scratches or marks that may occur over time, ensuring a consistently attractive appearance. Additionally, stainless steel is easy to clean and maintain. The smooth surface of the textured stainless steel sheets allows for easy removal of dirt, fingerprints, and other smudges, making it effortless to keep the lighting fixture looking polished and clean. Furthermore, stainless steel has excellent light reflectivity properties. The textured surface can enhance the way light is dispersed, creating interesting patterns and shadows. This can add a unique ambiance to the surrounding area and create a visually stunning effect. Lastly, stainless steel is a sustainable and eco-friendly material. It is 100% recyclable, making it an environmentally responsible choice for lighting fixtures. By using textured stainless steel sheets, we can contribute to reducing our carbon footprint and promoting a greener future. In conclusion, the benefits of using textured stainless steel sheets in decorative lighting fixtures are numerous. They add a visually appealing element, are durable and long-lasting, easy to clean and maintain, have excellent light reflectivity properties, and are environmentally friendly. These advantages make textured stainless steel sheets an excellent choice for creating stunning and sustainable lighting fixtures.

- Q: Stainless steel without fingerprint processing how to get?

- Anti fingerprint (also known as non fingerprint) stainless steel plate is a protective layer treatment process is extremely thin and solid formed on the surface of stainless steel by nano coating technology, the stainless steel surface can not only achieve the anti fingerprint effect, also can improve the anti corrosion resistance;

- Q: What's the difference between stainless steel 8K and BA?. How to distinguish from the surface of materials?

- The 304430 BA of stainless steel can achieve the effect of 6K or 8K. Is the most direct Kanban lines then some words to be processed is certainly not 8K, BA is 8K achieve brightness over direct annealing processing completely invisible plate lines in acid corrosion in the grinding process has damage the surface of the protective layer.

- Q: Are stainless steel sheets suitable for roofing applications?

- Yes, stainless steel sheets are suitable for roofing applications. They are durable, corrosion-resistant, and provide excellent strength and longevity. Additionally, stainless steel sheets offer good aesthetic appeal and can withstand harsh weather conditions, making them a reliable choice for roofing projects.

- Q: How do you prevent fingerprints on stainless steel sheets?

- There are several steps you can take to prevent fingerprints on stainless steel sheets: 1. Start by thoroughly cleaning the surface of the stainless steel sheets using a mild detergent or stainless steel cleaner. This will eliminate any existing fingerprints or smudges. 2. When handling the sheets, wear gloves to avoid transferring natural oils from your hands onto the surface. Cotton or nitrile gloves are recommended as they offer a good grip and leave no residue. 3. Minimize direct contact with the stainless steel surface as much as possible. This can be achieved by using specialized tools or wearing gloves when handling and installing the sheets. 4. Consider applying a protective coating specifically designed for stainless steel. These coatings create a barrier that repels fingerprints and simplifies the cleaning process. Be sure to follow the manufacturer's instructions for proper application. 5. Use a soft microfiber cloth when cleaning the stainless steel sheets. Microfiber is gentle on the surface and helps prevent streaks and fingerprints. Avoid using abrasive materials or rough scrubbers that can damage the stainless steel finish. 6. Establish a regular cleaning routine to remove any fingerprints or smudges that may appear over time. Dilute a mild detergent in warm water and use a soft cloth or sponge to wipe down the stainless steel sheets. Rinse with clean water and thoroughly dry. By following these preventive measures and cleaning techniques, you can significantly reduce the visibility of fingerprints on stainless steel sheets and keep them looking clean and flawless.

- Q: Are stainless steel sheets resistant to chemicals and acids?

- Yes, stainless steel sheets are resistant to chemicals and acids. Stainless steel contains a high percentage of chromium, which forms a protective layer on the surface of the metal, making it highly resistant to corrosion and damage from chemicals and acids. This corrosion-resistant property is further enhanced by the addition of other elements such as nickel and molybdenum. Stainless steel sheets are widely used in various industries, including chemical processing, pharmaceuticals, food and beverage, and automotive, where they are exposed to aggressive chemicals and acids. The resistance of stainless steel to chemicals and acids makes it a reliable and durable material for applications that require resistance to corrosion and chemical attack.

- Q: What are the different methods of cutting stainless steel sheets?

- There are several methods for cutting stainless steel sheets, including shearing, laser cutting, waterjet cutting, plasma cutting, and abrasive cutting. Each method has its advantages and is suitable for different applications and thicknesses of stainless steel.

- Q: What are the benefits of using textured stainless steel sheets in retail displays?

- Using textured stainless steel sheets in retail displays offers several advantages. Firstly, they can give a modern and sleek look to any retail space, attracting customers and setting the store apart from competitors. Secondly, these sheets are highly durable, able to withstand wear and tear and maintain their appearance over time. Additionally, they are easy to clean and maintain, ensuring a high level of hygiene in the store. Moreover, their versatility allows for customization to fit any retail display needs. Lastly, these sheets are environmentally friendly, as stainless steel is recyclable and promotes sustainability. In conclusion, utilizing textured stainless steel sheets in retail displays enhances brand image, creates visually appealing displays, and provides a positive shopping experience for customers.

- Q: Are stainless steel sheets resistant to chemicals?

- Yes, stainless steel sheets are generally resistant to chemicals. Due to their high levels of chromium and nickel, stainless steel sheets exhibit excellent resistance to corrosion from a wide range of chemicals, making them suitable for various industrial and commercial applications.

- Q: Can stainless steel sheets be used in high-pressure environments?

- Yes, stainless steel sheets can be used in high-pressure environments. Stainless steel is known for its excellent strength and resistance to corrosion, making it suitable for applications that require high-pressure resistance. Stainless steel sheets can withstand high pressures without deforming or breaking, making them ideal for use in industries such as oil and gas, chemical processing, and power generation, where high-pressure environments are common. Additionally, stainless steel sheets can maintain their structural integrity and performance even at elevated temperatures, further enhancing their suitability for high-pressure applications.

Send your message to us

Color Coated Galvanized Steel Coil with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 7000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords