Hot-Dip Galvanized Steel Coil with High Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 7000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

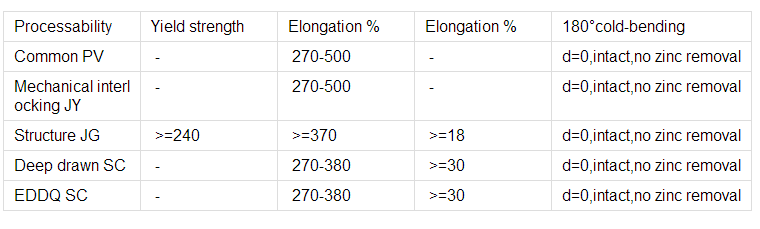

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:What are the different types of embossed patterns available for stainless steel sheets?

- There are several different types of embossed patterns available for stainless steel sheets, including diamond, quilted, linen, leather, and checker plate patterns.

- Q:How do you join stainless steel sheets together?

- Stainless steel sheets can be joined together through various methods, such as welding, riveting, bolting, or using adhesives. The specific joining technique depends on the application, the desired strength, and the aesthetic requirements.

- Q:Can stainless steel sheets be used for electromagnetic compatibility?

- Yes, stainless steel sheets can be used for electromagnetic compatibility. Stainless steel is a highly conductive material that can effectively shield against electromagnetic interference (EMI) and radio frequency interference (RFI). It can be used to create enclosures or shielding to protect sensitive electronic devices from external electromagnetic fields.

- Q:Are stainless steel sheets suitable for outdoor railings?

- Yes, stainless steel sheets are suitable for outdoor railings. Stainless steel is highly resistant to corrosion, making it a durable and long-lasting material for outdoor applications. It can withstand exposure to various weather conditions, including rain, snow, and sunlight, without rusting or deteriorating. Stainless steel also offers a sleek and modern appearance, making it a popular choice for outdoor railings.

- Q:904L stainless steel plate generally used in what industry is more?

- With high chromium content and adequate content of nickel, copper to make it strong acid resistant ability, especially for chloride crevice corrosion and stress corrosion cracking are highly resistant, not prone to pitting and cracking, pitting resistance slightly better with other steel, with good machinability and welding that can be used for pressure vessel.

- Q:Are stainless steel sheets resistant to alkalis?

- Yes, stainless steel sheets are generally resistant to alkalis. Stainless steel is known for its corrosion resistance, and it has a high resistance to a wide range of chemicals, including alkalis. This resistance is due to the presence of chromium in the alloy, which forms a protective oxide layer on the surface of the stainless steel, preventing the alkalis from corroding or damaging the material. However, it is important to note that the level of resistance may vary depending on the specific grade and composition of the stainless steel.

- Q:How do I prevent stress relaxation on stainless steel sheets?

- To prevent stress relaxation on stainless steel sheets, it is important to avoid subjecting them to excessive heat or prolonged periods of high stress. Additionally, carefully selecting the appropriate grade of stainless steel and implementing proper handling and storage techniques can help minimize stress relaxation.

- Q:What is the modulus of elasticity of stainless steel sheets?

- The modulus of elasticity, also known as Young's modulus, is a measure of the stiffness or rigidity of a material. For stainless steel sheets, the modulus of elasticity typically ranges from 190 to 200 gigapascals (GPa). However, it is important to note that the modulus of elasticity can vary depending on the specific type and grade of stainless steel, as well as factors such as temperature and strain rate.

- Q:What are the benefits of using diamond plate stainless steel sheets in industrial flooring?

- There are several benefits of using diamond plate stainless steel sheets in industrial flooring. Firstly, diamond plate stainless steel sheets provide excellent durability and strength. The diamond pattern on the surface enhances the structural integrity of the sheets, making them highly resistant to wear and tear. This is particularly important in industrial settings where heavy machinery, equipment, and foot traffic can cause significant damage to regular flooring materials. The stainless steel construction also ensures that the sheets are corrosion-resistant, further extending their lifespan and reducing maintenance costs. Secondly, diamond plate stainless steel sheets offer superior slip resistance. The raised diamond pattern provides additional traction, making it easier and safer for workers to move around the industrial floor. This is essential in environments where spills, oils, or other liquids are present, as it helps to prevent accidents and injuries caused by slip and falls. Additionally, diamond plate stainless steel sheets are hygienic and easy to clean. The smooth surface and corrosion-resistant properties of stainless steel make it resistant to dirt, grime, and bacteria buildup. This is crucial in industries such as food processing, pharmaceuticals, or healthcare, where maintaining a clean and sanitary environment is paramount. Moreover, diamond plate stainless steel sheets are aesthetically pleasing and can enhance the overall appearance of the industrial space. The diamond pattern adds a modern and industrial touch, which can help create a professional and visually appealing environment. Lastly, diamond plate stainless steel sheets are versatile and can be easily customized to fit various industrial flooring requirements. They are available in different sizes, thicknesses, and grades, allowing for flexibility in design and installation. This adaptability makes them suitable for a wide range of applications, from factory floors to warehouses, garages, and even outdoor areas. In conclusion, the benefits of using diamond plate stainless steel sheets in industrial flooring are their durability, slip resistance, hygiene, aesthetic appeal, and versatility. These advantages make them an excellent choice for industrial settings, ensuring a safe, long-lasting, and visually appealing flooring solution.

- Q:What is the general width range of stainless steel sheet? What are the common widths?

- Standard 3 M2 1220*2440 thickness from 1 to 12. The whole volume is hard to say.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-Dip Galvanized Steel Coil with High Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 7000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords