301 Stainless Steel

301 Stainless Steel Related Searches

302 Stainless Steel 300 Stainless Steel 305 Stainless Steel 321 Stainless Steel 201 Stainless Steel 300 Series Stainless Steel 431 Stainless Steel 304 Grade Stainless Steel 310 Stainless Steel Type 304 Stainless Steel 304l Stainless Steel Grade 304 Stainless Steel 410 Stainless Steel 400 Stainless Steel Stainless Steel 316 330 Stainless Steel 302 Stainless Steel Sheet Type 316 Stainless Steel 316 Grade Stainless Steel 304 Stainless Steel Pipe 316l Stainless Steel 304 Stainless Steel Magnetic Stainless Steel 303 Aisi 304 Stainless Steel Stainless Steel 316l 304 Stainless Steel Tubing 360 Stainless Steel Sus 304 Stainless Steel 309 Stainless Steel 430 Stainless Steel301 Stainless Steel Supplier & Manufacturer from China

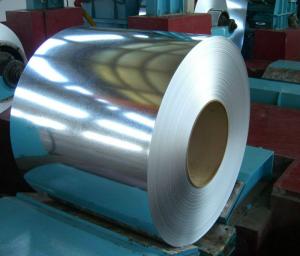

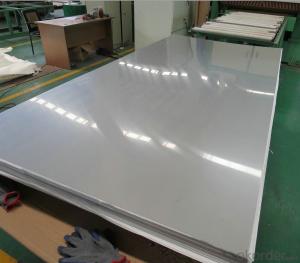

301 Stainless Steel is a type of austenitic stainless steel that is known for its excellent strength and corrosion resistance properties. This grade of stainless steel is widely used in various industries due to its ability to withstand harsh environments and maintain its integrity over time. The product's composition includes a higher carbon content compared to other stainless steel grades, which contributes to its enhanced strength and durability.301 Stainless Steel finds its application in a multitude of scenarios, such as in the manufacturing of automotive parts, architectural structures, and various engineering components. Its high strength and resistance to corrosion make it an ideal choice for applications where these properties are crucial for the product's performance and longevity. Whether it's used in the construction of bridges or in the production of precision instruments, 301 Stainless Steel stands out as a reliable and robust material.

As a wholesale supplier, Okorder.com offers a vast inventory of 301 Stainless Steel products to cater to the diverse needs of its customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the 301 Stainless Steel products they provide meet the highest industry standards. This makes them a reliable source for businesses and individuals seeking to incorporate this versatile and durable material into their projects.

Hot Products