Stainless Steel Round Bar 304_304L with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Round Bar 304_304L with High Quality

Details of Stainless Steel Round Bar 304_304L with High Quality

Name | Stainless Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

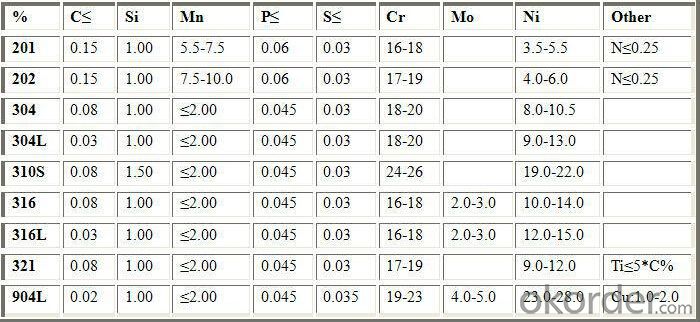

Specification of Stainless Steel Round Bar 304_304L with High Quality

CNBM Introduction of Stainless Steel Round Bar 304_304L with High Quality

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Stainless Steel Round Bar 304_304L with High Quality

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Can steel round bars be used in outdoor applications?

- Yes, steel round bars can be used in outdoor applications. Steel is a durable and corrosion-resistant material, making it suitable for various outdoor environments. However, it is essential to choose the right type of steel and apply appropriate protective coatings to ensure long-term performance and prevent rusting.

- Q: What is the difference between hot working and cold working of steel round bars?

- Hot working and cold working are two different methods used to shape and manipulate steel round bars. Hot working involves heating the steel to a high temperature, typically above its recrystallization temperature, and then shaping it through processes such as forging, rolling, or extrusion. This method helps to reduce the hardness and increase the ductility of the steel, making it easier to reshape and form into desired shapes. Hot working also helps to refine the grain structure of the steel, improving its mechanical properties. On the other hand, cold working is performed at or near room temperature without the need for heating the steel. It involves processes like cold rolling, drawing, or bending, where the steel is mechanically deformed to achieve the desired shape. Cold working increases the strength and hardness of the steel while reducing its ductility. It also causes strain hardening, which results in a finer grain structure and improved dimensional accuracy. In summary, the main difference between hot working and cold working of steel round bars lies in the temperature at which the processes are carried out and the resulting effects on the mechanical properties of the steel. Hot working is performed at high temperatures to increase ductility and refine grain structure, while cold working is done at or near room temperature to enhance strength, hardness, and dimensional accuracy.

- Q: Is HRB335 round steel or rib steel?

- H, R, and B are the first letters in English for hot-rolled (Hotrolled), ribbed (Ribbed) and reinforced (Bars) three words.The numbers behind HRB represent the mechanical properties of the material they produce. The specific value is the yield strength of the material, sigma S (or Sigma P0.2). HRB335, indicating rebar with a yield strength of 335MPa.

- Q: What are the advantages of using chromium-vanadium alloy steel round bars?

- Using chromium-vanadium alloy steel round bars has several advantages: 1. Exceptional Strength and Hardness: Chromium-vanadium alloy steel is renowned for its high strength and hardness. It possesses a strong tensile strength, making it ideal for heavy-duty applications and resistance against wear and tear. 2. Enhanced Durability: The incorporation of chromium and vanadium elements improves the durability of the alloy steel round bars. It offers excellent resistance to corrosion, oxidation, and high temperatures, making it perfect for harsh environments. 3. Versatility in Applications: Chromium-vanadium alloy steel round bars provide versatility in various applications. They are suitable for manufacturing tools, springs, gears, and other components requiring strength and durability. This alloy steel's versatility makes it highly favored in industries like automotive, aerospace, and construction. 4. Convenient Machinability: Chromium-vanadium alloy steel is relatively easy to machine and work with, offering convenience to manufacturers. It can be easily shaped, cut, and formed into desired sizes and shapes without compromising its mechanical properties. 5. Cost-Effective Option: Despite its exceptional properties, chromium-vanadium alloy steel round bars tend to be cost-effective when compared to other high-performance alloys. Hence, it is a popular choice for industries that require strong and durable materials within their budget. 6. Exceptional Fatigue Resistance: Chromium-vanadium alloy steel demonstrates exceptional fatigue resistance, making it suitable for applications involving repetitive stress or cyclic loading. It can withstand repeated use and maintain its structural integrity over an extended period. In conclusion, chromium-vanadium alloy steel round bars offer a combination of high strength, enhanced durability, versatility, and cost-effectiveness. These advantages make it the preferred material choice for various industrial applications where reliability and performance are of utmost importance.

- Q: What are the different surface hardness options for steel round bars?

- Steel round bars can exhibit varying degrees of surface hardness, depending on the specific requirements and applications. There are several options available for achieving different levels of surface hardness in steel round bars: 1. Soft or annealed: At the lowest end of the surface hardness spectrum, steel is subjected to a heating and gradual cooling process to reduce internal stress and enhance ductility. Soft or annealed steel is easier to machine and shape, but it possesses lower strength and wear resistance. 2. Normalized: By heating steel to a predetermined temperature and subsequently cooling it in ambient air, the grain structure is refined, resulting in improved mechanical properties and increased hardness compared to annealed steel. 3. Quenched and tempered: This heat treatment process involves heating steel to high temperatures and quickly cooling it in a quenching medium like oil or water. The rapid cooling hardens the steel's surface, while the subsequent tempering process alleviates internal stresses and enhances toughness. Quenched and tempered steel round bars exhibit high levels of hardness and strength, making them suitable for applications requiring resistance to wear and impact. 4. Induction hardened: Through induction hardening, the surface of a steel round bar is selectively heated using an induction coil. This localized heating is followed by rapid quenching, resulting in a hardened surface layer that exhibits increased wear resistance. The core of the steel remains unaffected, retaining its toughness. 5. Case hardened: Also known as carburizing, case hardening involves introducing carbon into the surface layer of the steel round bar. This can be achieved by exposing the steel to a carbon-rich gas or heating it with a carbon-containing material. The carbon diffuses into the surface, increasing its hardness while leaving the core relatively softer. Case hardened steel round bars possess a tough core with a wear-resistant surface. These examples represent only a fraction of the available surface hardness options for steel round bars. The choice of hardness depends on specific application requirements such as required strength, wear resistance, and toughness.

- Q: What are the properties of steel round bars?

- Steel round bars have several properties that make them highly desirable for a wide range of applications. Firstly, they possess exceptional strength and durability, making them suitable for load-bearing structures and heavy-duty machinery. Additionally, steel round bars exhibit excellent corrosion resistance, allowing them to withstand harsh environmental conditions without compromising their integrity. They also have a high melting point and can withstand extreme temperatures, making them ideal for applications that involve heat or fire. Furthermore, steel round bars can be easily machined, welded, and fabricated, providing flexibility in design and construction processes. Lastly, they offer good dimensional stability and precise tolerances, ensuring consistent performance and reliability in various industrial and construction settings.

- Q: Specifications of the same kind of galvanized round bar more expensive than round steel?

- The general market price than ordinary steel galvanized steel bar of your 2000-3000 dollars per ton, according to your purchase requirements, price range of relatively large fluctuations, such as whether to open a formal invoice, transport distance, purchase quantity, relationship with your level of economic development, the developed area of fierce market competition, the price is relatively low. The prices and prices of large factories and small factories are not the same. The prices of big factories are generally high, and the prices of small factories are low.

- Q: Are steel round bars suitable for marine applications?

- Yes, steel round bars are a viable option for marine applications. Steel is renowned for its robustness, endurance, and ability to withstand corrosion, making it a popular preference for a wide range of marine uses. Marine structures, such as shipbuilding, offshore platforms, and marine equipment, frequently incorporate steel round bars. The exceptional tensile strength of steel enables it to endure the harsh conditions of the marine environment, including the corrosive impact of saltwater. Moreover, steel is easily fabricated and welded, rendering it a versatile material for marine applications. Nevertheless, it is crucial to consider the specific requirements of the marine application and select the most suitable type of steel round bar. Duplex stainless steel, for instance, surpasses standard carbon steels in terms of corrosion resistance and is frequently favored for marine applications. Additionally, proper maintenance and the application of protective coatings are imperative to guarantee the longevity and performance of steel round bars in marine settings. In conclusion, steel round bars are a fitting choice for marine applications due to their strength, durability, and corrosion resistance. However, it is vital to choose the appropriate type of steel and implement adequate maintenance practices to ensure optimal performance in the marine environment.

- Q: Can steel round bars be used for making transmission towers?

- Certainly, transmission towers can be constructed using steel round bars. The construction industry frequently utilizes steel round bars owing to their robustness, longevity, and adaptability. Transmission towers necessitate materials capable of enduring harsh weather conditions, accommodating hefty loads, and ensuring structural steadiness. Steel round bars effectively fulfill these criteria, rendering them a fitting option for erecting transmission towers. Moreover, steel round bars can be effortlessly fabricated and welded, permitting the swift and efficient construction and installation of transmission towers.

- Q: Can steel round bars be used for making exercise equipment?

- Steel round bars are a viable option for manufacturing exercise equipment due to their durability and strength. These bars are renowned for their ability to withstand heavy loads and provide stability during workouts, making them suitable for constructing various types of fitness equipment. Weightlifting bars, dumbbells, barbells, and other exercise equipment that require reliable materials can be created using steel round bars. Moreover, these bars can be easily machined, welded, and shaped into different forms, allowing for customization and versatility in exercise equipment design. As a result, steel round bars are favored by gym equipment manufacturers and fitness enthusiasts alike.

Send your message to us

Stainless Steel Round Bar 304_304L with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords