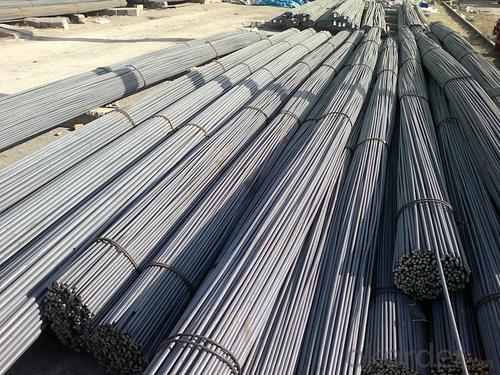

ROUND BAR

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Wire Rod Q235:

Steel Grade: Q235, Standard: GB Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Diameter Tolerance:±0.3mm 6.5mm can be drawing into 2mm/8.0mm can be drawing into 3mm

Brand Name: N-RIVER Place of Origin: Hebei, China Mainland Application: construction, building etc

Chemical Composition:

Please kindly find our chemistry of our material based on Q235 as below for your information

Trademark | Rank | Chemical composition (quality score) % | | ||||

C | Si | Mn | S | P | | ||

| | |||||||

| ≤ |

| ≤ | ≤ | | ||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | | ||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | | ||||

| | |||||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | | |||||

≤16 | 16-40 | | ≤16 | 16-40 | | ||

≥ | | ≥ | | ||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

Usage and Applications of Wire Rod Q235:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Packaging & Delivery of Wire Rod Q235:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

- Q: How do you store steel round bars to prevent damage?

- To store steel round bars and prevent damage, there are several important steps to follow. Firstly, it is crucial to keep the bars in a dry and well-ventilated area to avoid moisture buildup, which can lead to rusting. Moisture can also cause the bars to become brittle and weaken over time. Next, it is advisable to store the round bars horizontally rather than vertically. This prevents warping or bending due to the weight of the bars pressing down on each other. If vertical storage is necessary, it is essential to use appropriate racks or supports that evenly distribute the weight. It is also important to avoid stacking the bars too high, as excessive weight can cause deformation or collapse. If stacking is unavoidable, ensure sturdy supports are used and the weight is evenly distributed across the stack. Additionally, it is advisable to separate different sizes or types of steel round bars to prevent scratching or damage. This can be achieved by using separators or dividers to create distinct compartments for each type of bar. Lastly, regularly inspect the stored round bars for any signs of rust, corrosion, or damage. If any issues are detected, take necessary measures to address them promptly. This may involve applying rust inhibitors, cleaning the bars, or contacting professionals for further assistance. By following these storage guidelines, you can effectively protect steel round bars from damage and ensure their longevity and quality.

- Q: What are the advantages of using nickel-chromium-silicon alloy steel round bars?

- There are several advantages of using nickel-chromium-silicon alloy steel round bars. Firstly, this type of alloy steel offers excellent corrosion resistance, making it suitable for various applications in corrosive environments. Secondly, its high strength and toughness properties make it ideal for applications requiring heavy-duty and high-stress resistance. Additionally, nickel-chromium-silicon alloy steel round bars possess good high-temperature stability, allowing them to withstand elevated temperatures without significant deformation or loss of mechanical properties. Lastly, this alloy steel is known for its excellent weldability and machinability, enabling easy fabrication and customization according to specific requirements.

- Q: Can steel round bars be used in the production of medical equipment?

- Medical equipment can indeed utilize steel round bars. This is because steel is a widely employed material in the production of medical devices and equipment. Its strength, durability, and versatility make it a popular choice. By utilizing steel round bars, one can fashion various components of medical equipment, including surgical instruments, orthopedic implants, diagnostic tools, and hospital furniture. Steel possesses desirable properties, such as resistance to corrosion and the ability to be sterilized, rendering it suitable for use in the medical sector where hygiene and patient safety are paramount. Furthermore, steel round bars can be easily machined and fabricated into different shapes and sizes, allowing for the customization of medical equipment to fulfill specific requirements.

- Q: What is the yield strength of a steel round bar?

- When considering the design or selection of materials for structural applications, it is crucial to take into account the yield strength of a steel round bar. The yield strength refers to the stress or force that the bar can withstand before it undergoes deformation or permanent shape change. The specific grade or type of steel being utilized can cause variations in the yield strength. For instance, common grades like A36, 1018, and 4140 typically exhibit yield strengths ranging from 36,000 psi to 100,000 psi. However, it is important to bear in mind that factors such as heat treatment, manufacturing processes, and the presence of alloying elements in the steel composition can also impact the yield strength. Therefore, it is highly recommended to consult the material specifications or conduct thorough testing to accurately determine the yield strength of a steel round bar for a given application.

- Q: What are the different types of steel round bars used in the manufacturing of shafts?

- When manufacturing shafts, various types of steel round bars are commonly used. The selection of the steel round bar depends on the specific application and requirements of the shaft. Here are some of the frequently utilized types: 1. Carbon Steel Round Bars: These round bars are the most commonly used in shaft manufacturing. Carbon steel provides good strength and toughness, making it suitable for a range of shaft applications. 2. Alloy Steel Round Bars: By adding elements like chromium, nickel, or molybdenum to carbon steel, alloy steel round bars are created. This enhances the strength, hardness, and wear resistance of the shaft, making it appropriate for demanding applications. 3. Stainless Steel Round Bars: Stainless steel is highly resistant to corrosion and offers excellent mechanical properties. It is commonly used in shafts that require resistance to corrosion, high temperatures, or harsh environments. 4. Tool Steel Round Bars: Tool steel round bars are renowned for their exceptional hardness, toughness, and wear resistance. They are used in shafts for cutting tools, molds, and dies that necessitate high performance and durability. 5. High-Speed Steel Round Bars: Primarily used in shafts for cutting tools such as drills, mills, and taps, high-speed steel round bars possess excellent heat resistance and can withstand high cutting speeds without losing their hardness. 6. Mild Steel Round Bars: Mild steel round bars are low carbon steel bars that offer good weldability and machinability. They are commonly used in shafts for less demanding applications that do not require high strength or hardness. Considering the specific requirements, such as strength, hardness, corrosion resistance, and temperature resistance, is crucial when choosing the appropriate type of steel round bar for manufacturing shafts.

- Q: Can steel round bars be used in the construction industry?

- Yes, steel round bars can be commonly used in the construction industry. They are versatile and widely used for various structural applications. Steel round bars offer high strength and durability, making them suitable for supporting heavy loads and providing structural stability in buildings, bridges, and other construction projects. They can be used as reinforcement in concrete structures, such as columns, beams, and slabs, to enhance their strength and resist bending or cracking. Additionally, steel round bars are often utilized in the fabrication of steel frameworks, scaffolding, and other support systems in the construction industry. Their availability in different sizes and grades allows for flexibility in meeting specific construction requirements. Overall, steel round bars are a vital component in the construction industry due to their strength, versatility, and ability to withstand demanding conditions.

- Q: What are the different types of steel round bar alloys used in the construction industry?

- There are several types of steel round bar alloys commonly used in the construction industry. Some of the most popular ones include carbon steel, stainless steel, and alloy steel. Carbon steel is a widely used option due to its high strength and affordability. Stainless steel is preferred for its corrosion resistance properties, making it suitable for environments with high moisture or chemical exposure. Alloy steel, on the other hand, is known for its enhanced mechanical properties and durability, making it ideal for heavy-duty applications in construction.

- Q: What is the composition of steel round bars?

- Steel round bars are typically composed of iron and carbon, with small amounts of other elements such as manganese, silicon, and sulfur. The exact composition can vary depending on the specific grade and intended use of the steel.

- Q: What is the difference between a centerless ground and a hot rolled steel round bar?

- Two distinct types of steel bars are the centerless ground steel round bar and the hot rolled steel round bar. To begin with, the manufacturing process for each type varies. The centerless ground steel round bar is produced by passing it through a centerless grinder, which eliminates any surface imperfections and ensures a precise and smooth finish. This process guarantees tight tolerances and a consistent diameter throughout the bar's length. On the other hand, the hot rolled steel round bar is created by subjecting the steel billet to extremely high temperatures and then rolling it through a series of mills to achieve the desired shape and size. As a result, the surface finish of hot rolled steel bars is rougher compared to centerless ground steel bars. In terms of physical properties, centerless ground steel bars generally exhibit a higher level of dimensional accuracy and straightness due to the precision grinding process. This makes them suitable for applications requiring tight tolerances and precise measurements, such as the manufacturing of machinery parts or precision tools. Conversely, hot rolled steel round bars are renowned for their strength and durability. The heating and rolling process imparts desirable mechanical properties to the steel, such as increased hardness and toughness. These bars are commonly used in general construction, structural applications, and fabrication projects where strength and reliability are paramount. In conclusion, the key distinction between a centerless ground steel round bar and a hot rolled steel round bar lies in their manufacturing processes, surface finish, and intended applications. While centerless ground bars offer superior dimensional accuracy and smoothness, hot rolled bars are valued for their strength and resilience. The choice between the two depends on the specific requirements of the application at hand.

- Q: Can steel round bars be used for making body panels?

- Yes, steel round bars can be used for making body panels. Steel is a commonly used material in the automotive industry due to its strength, durability, and formability. Round bars can be shaped, welded, and formed into various body panel shapes, providing structural support and protection. However, it's important to note that steel round bars might not be the ideal choice for all body panels, as they can be heavier compared to alternative materials such as aluminum or carbon fiber. The decision to use steel round bars for body panels depends on factors such as the specific vehicle application, desired weight reduction, and cost considerations.

Send your message to us

ROUND BAR

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords