Low Carbon Steel C10/C15/C22/C25 Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low Carbon Steel C10/C15/C22/C25 Round Bars

Product Description

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

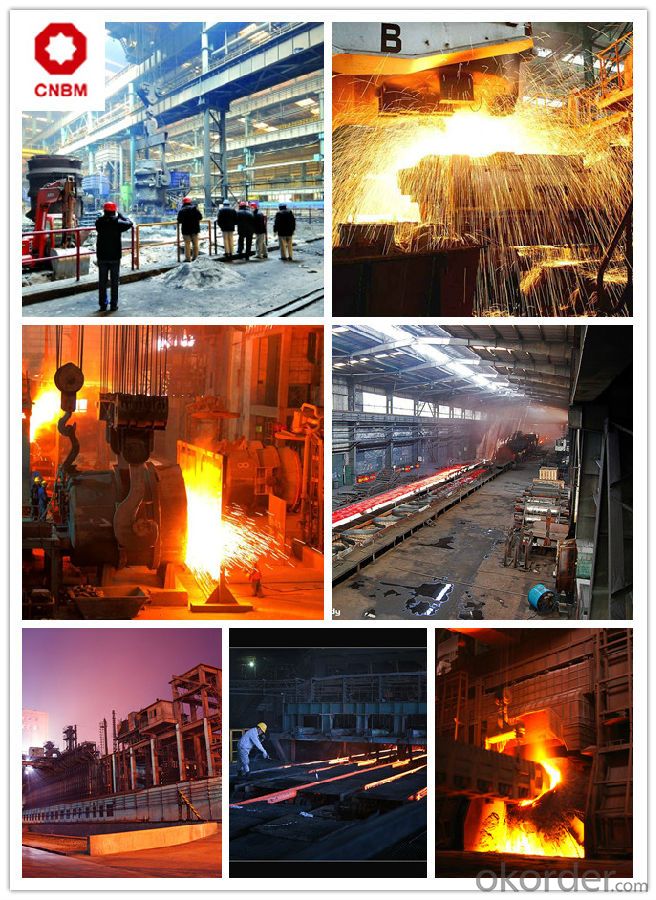

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: How do steel round bars perform under static or stationary loads?

- Steel round bars perform exceptionally well under static or stationary loads. Due to their high tensile and compressive strength, they can withstand heavy loads without significant deformation or failure. The structural integrity and stability of steel round bars make them a reliable choice for various applications where static or stationary loads are involved.

- Q: What are the advantages of using nickel-manganese alloy steel round bars?

- There are several advantages of using nickel-manganese alloy steel round bars. Firstly, these bars have excellent strength and toughness, making them suitable for applications that require high load-bearing capacity. Secondly, nickel-manganese alloy steel round bars exhibit good corrosion resistance, making them ideal for use in environments with high moisture or chemicals. Additionally, these bars offer good weldability, allowing for easy fabrication and assembly. Lastly, the inclusion of nickel and manganese in the alloy enhances the bars' heat resistance, making them suitable for applications involving high temperatures. Overall, the use of nickel-manganese alloy steel round bars provides a combination of strength, corrosion resistance, weldability, and heat resistance, making them a versatile choice for various industrial applications.

- Q: What are the different types of steel round bars used in the automotive chassis components?

- There are several different types of steel round bars that are commonly used in automotive chassis components. These types of steel are chosen based on their specific properties and performance requirements for different components of the chassis. 1. Mild Steel Round Bars: Mild steel is the most commonly used type of steel round bar in automotive chassis components. It offers a good balance between strength, durability, and cost-effectiveness. Mild steel round bars are used in various chassis components such as brackets, supports, and reinforcements. 2. High-Strength Low-Alloy (HSLA) Steel Round Bars: HSLA steel round bars are made with a combination of low carbon content and small amounts of alloying elements such as manganese, phosphorus, and chromium. This type of steel provides higher strength and improved formability compared to mild steel. HSLA steel round bars are often used in critical chassis components like control arms, suspension components, and steering linkages. 3. Boron Steel Round Bars: Boron steel round bars are known for their exceptional strength and resistance to deformation. These bars are alloyed with boron, which imparts high hardenability and toughness to the steel. Boron steel round bars are primarily used in safety-critical chassis components like reinforced door beams and crash structures. 4. Stainless Steel Round Bars: Stainless steel round bars are corrosion-resistant and offer excellent strength and durability. While not as commonly used in automotive chassis components, stainless steel round bars may be utilized in certain specialized components that require resistance to rust and corrosion, such as exhaust system components or parts exposed to harsh environmental conditions. 5. Alloy Steel Round Bars: Alloy steel round bars are made by adding various alloying elements such as nickel, chromium, and molybdenum to enhance specific properties like strength, hardness, and wear resistance. These bars are often used in high-performance chassis components like drive shafts, axles, and gears. In summary, the different types of steel round bars used in automotive chassis components include mild steel, high-strength low-alloy steel, boron steel, stainless steel, and alloy steel. The selection of the appropriate type depends on the specific requirements of each component, including strength, durability, formability, and corrosion resistance.

- Q: How do you calculate the length of a steel round bar?

- To calculate the length of a steel round bar, measure the distance from one end to the other using a ruler, tape measure, or any other measuring tool.

- Q: Requirements for groove welding of grade 22mm round steel and manual arc welding

- On the lathe, the car C9 chamfer (the car is sharp and difficult to weld, the car's chamfer is too small, the root is not welded).When welding, pull apart the gap of 2mm above the root clearance, the condition allows the edge to rotate while welding, otherwise it can only be welded in all positions.

- Q: Can steel round bars be welded?

- Yes, steel round bars can be welded. Welding is a common method used to join steel round bars together. The process involves heating the steel bars to a high temperature and applying pressure to fuse them together. This allows for the creation of strong and durable connections between the steel round bars. However, it is important to ensure that the appropriate welding techniques and equipment are used to achieve a high-quality weld.

- Q: What are the different types of steel used in manufacturing round bars?

- Round bars in manufacturing can be made from various types of steel. The most commonly used types include: 1. Carbon Steel: This is the go-to steel for manufacturing round bars due to its strength and durability. It mainly consists of iron and carbon and finds application in construction, automotive, and machinery. 2. Alloy Steel: By adding elements like manganese, nickel, chromium, and molybdenum to carbon steel, alloy steel is formed. This enhances its strength and hardness, making it suitable for applications that demand high strength and resistance to wear and tear. 3. Stainless Steel: A type of alloy steel, stainless steel contains a minimum of 10.5% chromium. This high chromium content gives it excellent corrosion resistance, making it ideal for applications exposed to moisture or chemicals. Stainless steel round bars are commonly used in kitchen utensils, medical equipment, and automotive parts manufacturing. 4. Tool Steel: Tool steel is an alloy steel designed specifically for high hardness, wear resistance, and heat resistance. It is commonly used in manufacturing cutting tools, dies, and molds. Tool steel round bars are usually made from high-carbon steel with additional elements like tungsten, vanadium, or cobalt. 5. Bearing Steel: Bearing steel is an alloy steel specifically formulated for bearing applications. It is characterized by its high hardness, wear resistance, and fatigue strength. Bearing steel round bars are widely used in bearing manufacturing for industries like automotive, aerospace, and industrial machinery. These examples demonstrate the range of steel types available for manufacturing round bars. The specific choice of steel depends on the desired properties and requirements of the application at hand.

- Q: Are steel round bars susceptible to rust?

- Steel round bars are indeed susceptible to rust. Rust is the result of a chemical reaction between iron and oxygen in the presence of moisture. Since steel is primarily made of iron, it can rust when exposed to air and moisture. However, the susceptibility to rust can be reduced by taking certain preventive measures. Steel round bars can be coated with protective layers such as paint, oil, or galvanized coatings to create a barrier between the steel and the surrounding environment, thus preventing or delaying the onset of rust. Regular maintenance, including cleaning and reapplying protective coatings, can further help in minimizing the risk of rust formation on steel round bars.

- Q: Can steel round bars be used for making crankshafts?

- Yes, steel round bars can be used for making crankshafts. Crankshafts are important components in engines that convert the reciprocating motion of the pistons into rotational motion. Steel is a preferred material for crankshafts due to its high strength, durability, and ability to withstand the stress and load generated during engine operation. Steel round bars are often used for making crankshafts as they provide a solid and reliable foundation for the rotating assembly. The round shape of the bars allows for easy machining and shaping into the desired crankshaft design. Additionally, steel can be heat-treated to further enhance its mechanical properties, such as hardness and fatigue resistance, making it ideal for the demanding conditions and high-performance requirements of crankshafts in various engine applications.

- Q: Can steel round bars be used in high-temperature environments?

- Yes, steel round bars can be used in high-temperature environments. However, the specific type of steel and its composition need to be carefully chosen to ensure it has the necessary heat resistance properties, such as high melting point and good strength retention at elevated temperatures.

Send your message to us

Low Carbon Steel C10/C15/C22/C25 Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords