Carbon Steel Bar 1035 S35C C35

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Steel Bar 1035 S35C C35

Product Description

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

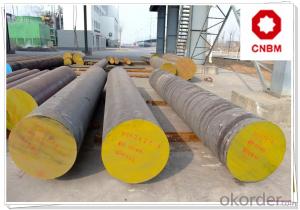

Products Show

Product Overviews

Description | Carbon Steel Rod/Carbon Steel Bar,carbon steel rod,carbon steel shaft,mild steel bar, Mild steel shaft,ms bar | |

Material | ASTM | 1005, 1006, 1008, 1010, 1015, 1020, 1025, 1030, 1035, 1040, 1045, 1050, 1055, 1060, 1065, 1070, 1080, 1084, 1016, 1022 |

DIN | Ck10, Ck15, Ck22, Ck25, Ck30, Ck35, Ck40,Ck45, Ck50, 30Mn4, 40Mn4 | |

BS | 040A04, 095M15, 045M10, 080A40, 045M10, 080M50 | |

JIS | S09CK, S9CK, S10C, S15C, S20C, S25C, S30C, S35C, S40C, S45C, S50C, S55C, S58C, SB45, S30C, S40C, S45C, S53C | |

Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| Section shape | Round, square, hexagonal, flat, angle | |

| Surface | Black painted, galvanized | |

Specifications | Round bar | Diameter: 4mm~1200mm |

Angle bar | Size: 3mm*20mm*20mm~12mm*800mm*800mm | |

Square bar | Size: 4mm*4mm~100mm*100mm | |

Flat bar | Thickness: 2mm~100mm | |

Width: 10mm~500mm | ||

| Hexagonal | Size: 4mm~800mm | |

Length | 2m, 4m, 5.8m, 6m, 11.8m, 12m or as required. | |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What are the advantages of using cobalt-alloy steel round bars?

- Using cobalt-alloy steel round bars in various industries and applications offers several advantages. Firstly, this type of steel is exceptionally strong and hard, providing resistance against wear, corrosion, and high temperatures. This makes it suitable for demanding environments where other materials would quickly degrade. Secondly, cobalt-alloy steel maintains its shape and size even under extreme conditions, demonstrating excellent dimensional stability. This makes it ideal for applications that require precise tolerances and minimal deformation, such as in the aerospace and automotive industries. Moreover, cobalt-alloy steel retains its mechanical properties at elevated temperatures, showcasing excellent heat resistance. This makes it valuable in applications involving high-speed machining, cutting tools, and turbine components. Additionally, cobalt-alloy steel round bars are easily machined and fabricated, offering versatility and customization in various applications. Their high machinability and weldability make them suitable for use in manufacturing processes like forging, casting, and machining. Furthermore, cobalt-alloy steel round bars exhibit excellent fatigue resistance, ensuring long-lasting performance and durability. This makes them suitable for applications involving repetitive stress or cyclic loading, such as shafts, springs, and fasteners. Lastly, cobalt-alloy steel is biocompatible, making it suitable for medical and dental applications. Its corrosion resistance and biocompatibility properties make it commonly used in orthopedic implants, surgical tools, and dental instruments. In conclusion, the advantages of using cobalt-alloy steel round bars include exceptional strength, hardness, and dimensional stability, as well as heat resistance, machinability, fatigue resistance, and biocompatibility. These qualities make them valuable across a wide range of industries and applications, offering reliability, durability, and performance.

- Q: What are the different types of steel round bars used in the automotive aftermarket?

- In the automotive aftermarket, there is a wide variety of steel round bars used. Some commonly seen types include: 1. Carbon Steel Round Bars: Due to its exceptional strength and durability, carbon steel is widely employed in the automotive industry. It finds its application in heavy-duty performance areas like suspension components, drive shafts, and steering linkages. 2. Alloy Steel Round Bars: Alloy steel, which is steel combined with other elements to enhance its mechanical properties, is prevalent in the automotive aftermarket. Applications requiring high strength, such as crankshafts, camshafts, and axles, commonly use alloy steel. 3. Stainless Steel Round Bars: Noted for its resistance to corrosion and attractive appearance, stainless steel is often preferred for automotive aftermarket applications in harsh environments. Exhaust systems, trim components, and decorative elements are examples that benefit from stainless steel's resistance. 4. Tool Steel Round Bars: Tool steel, a specialized high-carbon steel, is designed specifically for tooling and machining applications. In the automotive aftermarket, it is widely used for manufacturing specialized tools, dies, and molds. 5. Bearing Steel Round Bars: Bearing steel, another type of high-carbon steel, is tailored for bearing applications. In the automotive aftermarket, bearing steel is commonly utilized for manufacturing bearings and other rotating components. These examples represent just a small sample of the steel round bars found in the automotive aftermarket. The choice of steel for each specific application will depend on factors such as desired strength, durability, and resistance to corrosion.

- Q: Are steel round bars susceptible to rust?

- Steel round bars are indeed susceptible to rust. Rust is the result of a chemical reaction between iron and oxygen in the presence of moisture. Since steel is primarily made of iron, it can rust when exposed to air and moisture. However, the susceptibility to rust can be reduced by taking certain preventive measures. Steel round bars can be coated with protective layers such as paint, oil, or galvanized coatings to create a barrier between the steel and the surrounding environment, thus preventing or delaying the onset of rust. Regular maintenance, including cleaning and reapplying protective coatings, can further help in minimizing the risk of rust formation on steel round bars.

- Q: How do you prevent warping of steel round bars during machining?

- To prevent warping of steel round bars during machining, there are several measures that can be taken: 1. Proper Material Selection: Choosing the right type of steel with appropriate mechanical properties is crucial. Steel with lower carbon content and controlled alloying elements can help reduce the risk of warping during machining. 2. Pre-Machining Stress Relief: Steel round bars often have internal stresses that can lead to warping during machining. Conducting a stress relief process like annealing or normalizing before machining can help eliminate these internal stresses and minimize warping. 3. Controlled Machining Process: Employing proper machining techniques is vital to prevent warping. This includes using a rigid and stable machine setup, ensuring proper tool geometry and sharpness, and maintaining appropriate cutting speeds and feeds. Continuous monitoring of cutting forces and temperatures can also help in detecting any abnormal conditions that may contribute to warping. 4. Minimizing Heat Build-Up: Excessive heat generated during machining can cause localized expansion and lead to warping. To prevent this, coolant or lubricant should be used to dissipate heat and reduce friction between the tool and the workpiece. Adequate cooling can help maintain a stable temperature and prevent warping. 5. Proper Fixturing: When machining long steel round bars, using suitable fixtures or supports can help prevent excessive deflection or bending. This ensures that the bar remains straight and stable during machining, reducing the chances of warping. 6. Post-Machining Stress Relief: After machining, stress can still be present in the steel round bars. Performing a post-machining stress relief process, such as tempering or normalization, can help further relieve any residual stresses and minimize the risk of warping. By implementing these measures, the risk of warping during machining of steel round bars can be significantly reduced, leading to improved dimensional accuracy and overall quality of the machined parts.

- Q: What are the different types of steel round bars used in the automotive braking systems?

- There are several different types of steel round bars that are commonly used in automotive braking systems. These types of steel are specifically chosen for their strength, durability, and ability to withstand the high temperatures and pressures that are generated during braking. One commonly used type of steel round bar is carbon steel. This type of steel is known for its high strength and excellent hardness. Carbon steel round bars are often used in the manufacturing of brake rotors and brake drums. They are able to withstand the friction and heat generated during braking, ensuring reliable performance and longevity. Another type of steel round bar used in automotive braking systems is stainless steel. Stainless steel is highly resistant to corrosion and rust, making it ideal for brake lines and fittings. It also has good heat resistance properties, allowing it to withstand the thermal stresses generated during braking. Some automotive braking systems also utilize alloy steel round bars. Alloy steel is a combination of different metals, such as chromium, nickel, and molybdenum, which enhance its mechanical properties. Alloy steel round bars are known for their high tensile strength and toughness, making them suitable for applications that require a high level of performance and durability. In addition to these commonly used types of steel round bars, there are also specialized types that are designed for specific applications within automotive braking systems. For example, heat-treated steel round bars are used in the manufacturing of brake calipers and pistons, as they can withstand the extreme temperatures generated by the friction between the brake pads and rotors. Overall, the choice of steel round bar in automotive braking systems depends on the specific requirements of the application, such as strength, durability, heat resistance, and corrosion resistance. By selecting the appropriate type of steel, automotive manufacturers can ensure the safety and reliability of their braking systems.

- Q: What are the environmental benefits of using steel round bars?

- Steel round bars offer several environmental benefits: 1. Recyclability: Steel is one of the most recycled materials globally, reducing the need for new steel production and saving energy and resources. Moreover, recycling steel decreases landfill waste and helps combat environmental pollution. 2. Durability: Steel round bars have a long lifespan and high durability, minimizing the need for frequent replacements and reducing material consumption. Additionally, their durability decreases maintenance and repair requirements, further minimizing environmental impact. 3. Energy efficiency: The production of steel round bars requires less energy compared to materials like concrete or wood. This energy-saving feature applies to the entire product lifecycle, including extraction, manufacturing, transportation, and installation. 4. Reduced carbon emissions: Steel production emits less carbon dioxide (CO2) than other materials. By using steel round bars, we can help lower greenhouse gas emissions and combat climate change. Additionally, steel production can utilize alternative energy sources like renewable energy, further reducing carbon emissions. 5. Versatility and weight reduction: Steel round bars are versatile and applicable in various construction uses. Their high strength-to-weight ratio enables the creation of lightweight structures, resulting in reduced material requirements. This not only decreases environmental impact but also lowers transportation costs and fuel consumption during delivery. 6. Fire-resistant properties: Steel round bars exhibit exceptional fire resistance, which helps prevent the spread of flames and minimizes damage to structures. Consequently, this reduces the necessity for fire retardant chemicals that may have adverse environmental effects. In conclusion, the utilization of steel round bars presents numerous environmental advantages, including recyclability, durability, energy efficiency, reduced carbon emissions, weight reduction, and fire resistance. By choosing steel round bars, we can contribute to a more sustainable and eco-friendly construction industry.

- Q: What are the advantages of using boron-alloy steel round bars?

- Using boron-alloy steel round bars in various applications offers several advantages. Firstly, compared to traditional carbon steel, boron-alloy steel has significantly higher strength. This increased strength enables the construction of lightweight and durable structures, reducing material costs and improving overall efficiency. Additionally, boron-alloy steel round bars exhibit excellent hardenability. This means they can be heat-treated to achieve desired properties such as increased hardness and wear resistance. This makes them ideal for demanding applications in industries like automotive and construction, where high strength and durability are necessary. Another advantage of boron-alloy steel round bars is their enhanced weldability. They can be easily welded without sacrificing their mechanical properties, allowing for seamless integration into various fabrication processes. This saves time and effort during assembly and ensures the structural integrity of the final product. Furthermore, boron-alloy steel round bars offer excellent resistance to abrasion and corrosion. This makes them suitable for use in harsh environments or applications where exposure to chemicals or moisture is common. The extended lifespan of the material reduces the need for frequent repairs or replacements, resulting in cost savings and improved productivity. Lastly, boron-alloy steel round bars are readily available and cost-effective compared to other high-strength steel alternatives. Their wide availability makes them a viable option for a range of applications, from manufacturing machinery to constructing infrastructure. In summary, the benefits of using boron-alloy steel round bars include higher strength and durability, improved hardenability, enhanced weldability, resistance to abrasion and corrosion, and cost-effectiveness. These advantages make them an excellent choice for various industries that require lightweight, strong, and long-lasting materials.

- Q: Can steel round bars be used in the oilfield equipment industry?

- Steel round bars have a wide range of applications in the oilfield equipment industry. They are highly favored for their remarkable strength, durability, and resistance to corrosion. In fact, they are extensively utilized in the manufacturing of numerous components and equipment, including drill collars, drill bits, valves, and pump shafts. By incorporating steel round bars, the oilfield industry ensures that its equipment can endure the severe conditions and immense pressures encountered during operations. Furthermore, steel round bars can be effortlessly welded and machined to meet particular specifications, adding to their versatility and making them an optimal selection for the oilfield sector.

- Q: Can steel round bars be used for making valves or fittings?

- Indeed, valves or fittings can be crafted using steel round bars. The utilization of steel is widespread in the production of valves and fittings owing to its commendable strength, resilience, and corrosion resistance. To cater to the specific criteria and demands, steel round bars can undergo machining or forging to attain the desired form for valves or fittings. Furthermore, heat treatment can be applied to steel round bars to bolster their mechanical attributes, rendering them suitable for applications involving elevated pressure or temperature. In conclusion, steel round bars present a versatile and dependable choice of material when it comes to manufacturing valves or fittings.

- Q: How do you cut steel round bars?

- To cut steel round bars, one can utilize various methods based on specific requirements and available tools. Here are a few commonly employed techniques: 1. Abrasive Cutting: By using a handheld angle grinder or chop saw equipped with an abrasive cutting wheel or disc, a groove is created on the surface of the round bar. Applying pressure and rotating the bar gradually allows the cutting wheel to slice through the steel. 2. Cold Saw: This specialized machine operates with a circular blade at a low speed, minimizing heat generation. The round bar is firmly clamped, and the cold saw's blade is lowered onto it to achieve precise cuts. 3. Band Saw: Another commonly used machine for steel round bar cutting, the band saw features a rotating toothed metal band that moves on two pulleys. The round bar is secured in a vise, and the band saw is adjusted to the desired angle and speed. The bar is then fed into the blade, resulting in smooth cuts. 4. Torch Cutting: For thicker steel round bars, oxy-fuel torch cutting is suitable. This method involves using a torch that combines oxygen and fuel gas, like acetylene, to produce a high-temperature flame. The round bar is heated until it becomes molten, and then a separate stream of oxygen is directed onto the heated area, causing rapid oxidation and enabling a cut. Irrespective of the chosen method, it is crucial to adhere to proper safety measures, including wearing protective goggles and gloves, and ensuring a stable work surface. Furthermore, using the appropriate cutting tools and techniques for the specific type of steel being cut is vital to achieve clean and precise results.

Send your message to us

Carbon Steel Bar 1035 S35C C35

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords