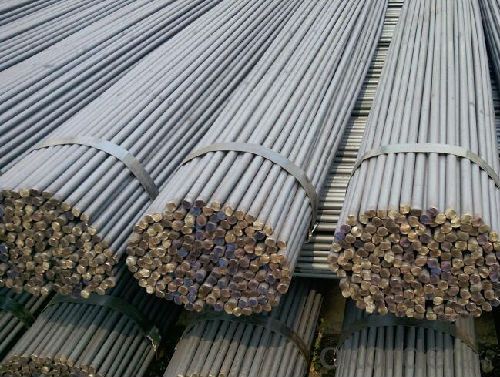

Hot rolled steel round bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering hot rolled steel round bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled steel round bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's steel round bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Grade: Q235, A36, SS400, S235JR

2. Feature: Unbreakable, grinding resistant and high impact value

3. Diameter: 8mm-150mm

4. Performance: Mainly for civil construction

5. Characteristics: Even hardness, no deformation, no breaking, no mal-roundness

6. Technique: Hot rolled

7. Mass: Mass (kg/m) = Diameter (mm) × Diameter (mm) × 0.00617

Usage and Applications of Steel Round Bar Products

1. Steel round bar products is used in construction and a large number of architectural and engineering structures. And it can be used in production of handrail, windows, machinery, telecom and curtain wall.

2. It can be used in the fields like metal mines, cement plants, water coal slurry, power stations and chemical industry.

3. Besides, we can supply some especial material steel round bar that can be used for main shaft of steamer, hummer shank, with big section and supper force.

4. Recommended watchcase factory, screw factory and other cold stamping products industry use.

Packaging & Delivery of Steel Round Bar Products

Packaging Detail: All goods are packed in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: 45 days

Trade terms: FOB, CFR, CIF

MOQ: 25 tons per specification; we can negotiate the quantity if the specification is normal or we have stock of one specification.

Weight: The price invoicing on theoretical weight basis or actual weight basis depends on customer’s request.

Shipment: The shipment of bulk break or container is depends on customer’s request and the situation of the port of destination.

Documents given: Full set of original clean on board bill of lading; Original signed commercial invoice; Original packing list; Policy of insurance; Certificate of origin and what the target market needs.

Production Flow of Steel Round Bar Products

Material prepare (billet) — heat up — rough rolling — precision rolling — cooling — packing — storage and transportation

Characteristics of Steel Round Bar Products

1. The steel in which the main interstitial alloying constituent is carbon in the range of 0.12–2.0%.

2. As the carbon percentage content rises, steel has the ability to become harder and stronger through heat treating; however it becomes less ductile.

3. Regardless of the heat treatment, higher carbon content reduces weld ability. In carbon steels, the higher carbon content lowers the melting point.

4. Quality should be in conformity with the specification of the manufacturer. Quantity and packing conditions should be in conformity with the term in the contract.

FAQ:

Q1: What makes stainless steel stainless?

A1: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q:What is the maximum temperature a steel round bar can withstand?

- The maximum temperature that a steel round bar can endure relies on various factors, including the particular type of steel, its composition, and the intended purpose. In general, most commonly used steel grades have an upper temperature limit of approximately 1,200 to 1,400 degrees Fahrenheit (650 to 760 degrees Celsius). However, certain stainless steels possess the ability to withstand higher temperatures, reaching up to 2,200 degrees Fahrenheit (1,200 degrees Celsius). Moreover, specialized heat-resistant alloys like Inconel or Hastelloy can withstand even greater temperatures, up to 2,500 degrees Fahrenheit (1,370 degrees Celsius) or beyond. To ensure the safe and efficient utilization of a specific steel round bar, it is essential to consult the manufacturer's specifications or conduct comprehensive research in order to ascertain its precise maximum temperature limit.

- Q:What are the advantages of using low-alloy steel round bars?

- Low-alloy steel round bars have become popular in various industries due to several advantages they offer. Firstly, they provide greater strength and durability compared to regular carbon steel, making them suitable for applications requiring high strength and resistance to wear and tear. The addition of alloying elements like manganese, chromium, and nickel enhances the hardness and toughness of the steel, ensuring its reliability and long-lasting nature. Secondly, low-alloy steel round bars exhibit excellent weldability and machinability. The presence of alloying elements allows for better control over the grain structure, resulting in improved weldability. This means that these bars can be easily welded and fabricated into complex shapes without compromising their structural integrity. Additionally, their machinability enables efficient processing and customization according to specific requirements. Furthermore, low-alloy steel round bars offer enhanced resistance to corrosion and atmospheric conditions. The alloying elements create a protective oxide layer on the surface, preventing rusting and deterioration over time. This makes them ideal for outdoor applications in harsh environments, such as construction, marine, and oil and gas industries. Moreover, low-alloy steel round bars are a cost-effective alternative to higher-alloy or stainless steel options. While providing similar strength and performance, low-alloy steel is generally more affordable, making it a viable option for projects with budget constraints. This cost-effectiveness, combined with their durability and versatility, makes low-alloy steel round bars a preferred choice for a wide range of applications. In conclusion, the advantages of low-alloy steel round bars include increased strength and durability, excellent weldability and machinability, resistance to corrosion, and cost-effectiveness. These properties make them a reliable and versatile material for various industries, contributing to their widespread use in numerous applications.

- Q:How do you check the quality of a steel round bar?

- Several factors need to be taken into account when checking the quality of a steel round bar. Firstly, it is crucial to assess the dimensions of the bar. This involves measuring its diameter, length, and straightness. Any deviation from the specified dimensions could indicate a lower quality bar. Next, it is important to inspect the surface condition of the steel round bar. It should be free from visible defects such as cracks, pits, or surface irregularities. Additionally, the surface should be smooth and without significant roughness or burrs. Moreover, the chemical composition of the steel round bar must be examined. This can be done through spectroscopic analysis or other testing methods. The composition should meet the required standards and specifications, as any deviations can impact the bar's strength and durability. Another crucial aspect to consider is the mechanical properties of the steel round bar. This involves testing its tensile strength, yield strength, and elongation. Specialized machines can be used for these tests to ensure that the bar meets the necessary strength requirements. Additionally, non-destructive testing methods such as ultrasonic testing or magnetic particle inspection can be employed to identify any internal or surface defects that may affect the bar's quality. Furthermore, it is essential to verify the bar's compliance with industry standards and certifications. This includes checking if the steel round bar meets the specifications set by organizations like ASTM International or ISO. Lastly, consulting reputable suppliers or manufacturers with a proven track record in producing high-quality steel round bars is advisable. They can provide documentation, certifications, and test reports to validate the quality of their products. To summarize, evaluating the dimensions, surface condition, chemical composition, mechanical properties, compliance with standards, and supplier's reputation are key steps in checking the quality of a steel round bar. By thoroughly examining these factors, one can ensure the reliability and performance of the steel round bar for its intended applications.

- Q:What are the different finishes available for steel round bars?

- Steel round bars are available in several finishes, each serving a specific purpose and offering distinct benefits. Some commonly used finishes include: 1. Hot Rolled: By heating the steel above its recrystallization temperature and rapidly cooling it, a rough and scaly surface texture is achieved. This finish provides excellent corrosion resistance and durability. 2. Cold Rolled: The steel is rolled at room temperature, resulting in a smooth and polished finish. Cold rolled steel round bars are known for their precise dimensions, tight tolerances, and improved surface finish. 3. Bright Drawn: This finish involves subjecting the steel round bars to a drawing process, where they are pulled through a die to achieve the desired shape and size. It leaves the surface smooth, bright, and free from imperfections. 4. Polished: Polishing is typically done after cold rolling or drawing the steel round bars. Abrasive materials or chemical treatments are used to remove surface imperfections and create a highly reflective finish. Polished steel round bars are commonly used for decorative purposes. 5. Ground: Grinding is a process where abrasive wheels are used to remove surface imperfections or irregularities from the steel round bars. This results in a smooth and even finish, making the bars suitable for applications requiring tight tolerances and uniformity. 6. Galvanized: Galvanizing involves dipping the steel round bars in a bath of molten zinc, creating a protective layer that prevents corrosion and increases their lifespan. This finish is ideal for outdoor applications or environments with high humidity or moisture. These various finishes offer different properties and appearances, allowing steel round bars to be used in industries such as construction, automotive, manufacturing, and engineering. It is important to consider the specific requirements and conditions of the intended use when selecting the appropriate finish for steel round bars.

- Q:What are the different types of steel alloys used for round bars?

- There are several different types of steel alloys used for round bars, each offering unique properties and characteristics that make them suitable for various applications. Some of the commonly used steel alloys for round bars include: 1. Carbon Steel: This is the most common type of steel alloy used for round bars. It contains primarily carbon and iron, and offers excellent strength and toughness. Carbon steel round bars are commonly used in construction, manufacturing, and general engineering applications. 2. Stainless Steel: This alloy contains chromium, which provides corrosion resistance and makes it suitable for applications where rust or oxidation is a concern. Stainless steel round bars are widely used in the food and beverage industry, as well as in marine and chemical industries. 3. Alloy Steel: This type of steel alloy is made by adding other elements such as manganese, nickel, or chromium to improve its mechanical properties. Alloy steel round bars are known for their high strength, hardness, and resistance to wear and tear. They are commonly used in automotive, aerospace, and machinery industries. 4. Tool Steel: Tool steel alloys are specifically designed to have high hardness, wear resistance, and toughness. They are used for making cutting tools, dies, and molds. Tool steel round bars are available in various grades, such as D2, O1, and A2, each with specific properties for different applications. 5. Duplex Steel: This alloy contains a combination of austenitic and ferritic stainless steels, offering a combination of high strength and corrosion resistance. Duplex steel round bars are used in applications where both strength and resistance to corrosion are required, such as in the oil and gas industry. These are just a few examples of the different types of steel alloys used for round bars. The specific choice of alloy depends on the desired properties and the intended application of the round bar.

- Q:Could you tell me what is the difference between steel pipe and round steel?

- The middle of the steel pipe is hollow, and the round steel is solid. When compared with the solid steel such as round steel, the steel tube has the same flexural strength and torsion strengthLight weight, is an economic section of steel, widely used in the manufacture of structural and mechanical parts, such as oil drilling pipe, automobile transmission shaft, bicycle frame and steel scaffolding used in construction.Making ring parts with steel tubes can improve data application rate, simplify manufacturing process, save data and work hours, such as rolling bearings, rings, Jack sleeves, etc., and have been widely used in steel pipe manufacture.

- Q:What are the advantages of using nickel-chromium-manganese alloy steel round bars?

- The advantages of using nickel-chromium-manganese alloy steel round bars include their excellent strength and durability, high resistance to corrosion and oxidation, good machinability, and the ability to withstand high temperatures and pressures. Additionally, this alloy offers good weldability and can be easily formed into various shapes and sizes, making it suitable for a wide range of applications in industries such as aerospace, automotive, and construction.

- Q:Are steel round bars prone to fatigue failure?

- Yes, steel round bars are generally prone to fatigue failure due to cyclic loading and repeated stress, especially when exposed to high loads or stress concentrations. However, factors such as material quality, design, and proper maintenance can help mitigate the risk of fatigue failure.

- Q:Can steel round bars be used in the manufacturing of home decor?

- Yes, steel round bars can definitely be used in the manufacturing of home decor. Steel round bars are versatile and durable materials that can be shaped, welded, and manipulated into various forms and designs. They can be used to create decorative elements such as candle holders, wall art, sculptures, furniture accents, and more. Steel round bars can be polished, painted, or left in their natural state to suit different interior design styles. Additionally, steel is a strong and long-lasting material, making it ideal for home decor items that need to withstand regular use and maintain their appearance over time.

- Q:How are steel round bars used in the manufacturing of mining equipment?

- Steel round bars are commonly used in the manufacturing of mining equipment due to their high strength and durability. These bars are often utilized as a key structural component in the construction of heavy machinery such as crushers, drilling rigs, and conveyor systems. They provide the necessary support and stability required to withstand the harsh operating conditions and heavy loads typically encountered in mining operations. Additionally, steel round bars can be machined and shaped to create various components such as shafts, pins, and gears, further enhancing the functionality and reliability of mining equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot rolled steel round bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords