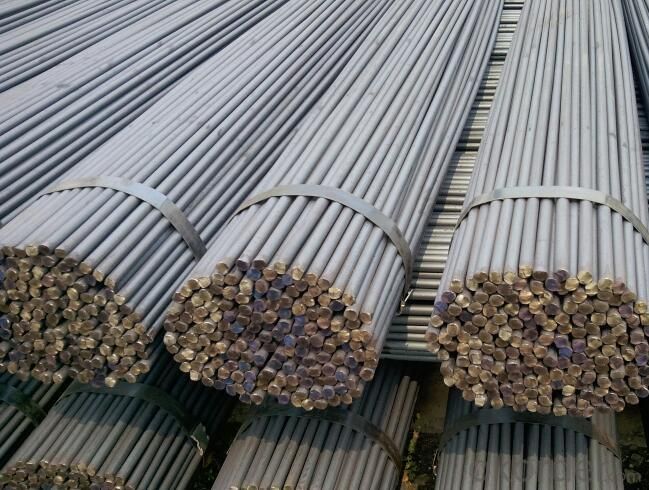

Hot Rolled Prime Low Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Prime Low Carbon Steel Round Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Prime Low Carbon Steel Round Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Prime Low Carbon Steel Round Bar are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

| ROUND BAR | |

| SIZE d(mm) | theoretical kg/m |

| 5.5 | 0.186 |

| 6 | 0.222 |

| 7 | 0.302 |

| 8 | 0.395 |

| 9 | 0.499 |

| 10 | 0.617 |

| 11 | 0.746 |

| 12 | 0.888 |

| 13 | 1.04 |

| 14 | 1.21 |

| 15 | 1.39 |

| 16 | 1.58 |

| 17 | 1.78 |

| 18 | 2 |

| 19 | 2.23 |

| 20 | 2.47 |

| 21 | 2.72 |

| 22 | 2.98 |

| 24 | 3.55 |

| 25 | 3.85 |

| 26 | 4.17 |

| 28 | 4.83 |

| 30 | 5.55 |

| 32 | 6.31 |

| 34 | 7.13 |

| 36 | 7.99 |

| 38 | 8.9 |

| 40 | 9.86 |

| 42 | 10.9 |

| 45 | 12.5 |

| 48 | 14.2 |

| 50 | 15.4 |

| 53 | 17.3 |

| 56 | 19.3 |

| 60 | 22.2 |

| 63 | 24.5 |

| 65 | 26 |

| 70 | 30.2 |

| 75 | 34.7 |

| 80 | 39.5 |

| 85 | 44.5 |

| 90 | 49.9 |

| 95 | 55.6 |

| 100 | 61.7 |

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q2: what is the difference between actual weight and theoretical weight?

A2: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request

Q3: How many tons of steel products could be loaded in containers?

A3: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: What is the density of a steel round bar?

- The density of a steel round bar depends on the specific type of steel being used, as there are various steel alloys with different densities. However, on average, the density of a steel round bar is usually around 7,800 kilograms per cubic meter (kg/m³).

- Q: What are the advantages of using nickel-molybdenum-chromium alloy steel round bars?

- The advantages of using nickel-molybdenum-chromium alloy steel round bars include excellent corrosion resistance, high strength and toughness, good weldability, and the ability to withstand extreme temperatures and pressures. These properties make the alloy steel round bars suitable for various applications in industries such as oil and gas, aerospace, and chemical processing, where durability and reliability are essential.

- Q: Are steel round bars prone to fatigue failure?

- Yes, steel round bars are prone to fatigue failure. Fatigue failure is the result of repeated cyclic loading or stress on a material, causing it to weaken and eventually fail, even when the applied stress is below its ultimate strength. Steel round bars, like any other structural material, are susceptible to fatigue failure due to their inherent characteristics. Fatigue failure in steel round bars can occur due to various factors, including improper design, inadequate material selection, manufacturing defects, or excessive cyclic loading. Factors such as surface defects, notches, stress concentrations, and corrosive environments can further accelerate the fatigue process. To mitigate the risk of fatigue failure, engineers and designers employ various strategies such as implementing appropriate design practices, selecting high-quality materials, conducting thorough inspections, applying stress-relieving treatments, and considering the impact of cyclic loading during the structural design phase. It is important to note that while steel round bars are prone to fatigue failure, the actual susceptibility depends on numerous factors, including the specific steel grade, loading conditions, environmental factors, and overall structural design. Therefore, it is crucial to carefully assess these factors and employ appropriate mitigation measures to ensure the safe and reliable performance of steel round bars in various applications.

- Q: What are the advantages of using nickel-manganese alloy steel round bars?

- Nickel-manganese alloy steel round bars provide numerous benefits in various applications. To begin with, these round bars exhibit exceptional strength and toughness. The incorporation of nickel and manganese significantly enhances the overall strength and durability of the steel, rendering it suitable for heavy-duty applications that demand high strength and resistance to wear and tear. As a result, industries such as construction, automotive, and manufacturing find these alloy steel round bars highly advantageous. Additionally, nickel-manganese alloy steel round bars possess outstanding corrosion resistance properties. The nickel content in the alloy imparts remarkable resistance to corrosion, making it ideal for use in harsh environments or situations where exposure to corrosive substances is common. Consequently, the lifespan of these round bars is extended, reducing the need for frequent maintenance or replacement. Moreover, these round bars demonstrate excellent heat resistance. They can withstand elevated temperatures without compromising their structural integrity, making them suitable for applications involving extreme heat or thermal cycles. Industries like aerospace, power generation, and oil and gas greatly benefit from this heat resistance property. Furthermore, nickel-manganese alloy steel round bars offer favorable weldability and machinability. The composition of the alloy facilitates easy welding and machining, allowing manufacturers to fabricate components or structures with ease. This versatility in processing makes the round bars highly adaptable to varying manufacturing processes and requirements. Moreover, these round bars exhibit good ductility and formability. The alloy's composition permits easy shaping or forming into various configurations without sacrificing its structural integrity. Consequently, they are suitable for applications that necessitate complex shapes or intricate designs. In conclusion, the advantages of utilizing nickel-manganese alloy steel round bars encompass exceptional strength, corrosion resistance, heat resistance, weldability, machinability, and formability. These properties make these round bars a dependable and versatile choice for a broad range of applications across different industries.

- Q: What are the different packaging options for steel round bars?

- The different packaging options for steel round bars usually include bundles, wooden crates, or steel frames.

- Q: Can steel round bars be used for making decorative items?

- Certainly, decorative items can indeed be created using steel round bars. With their ability to be shaped, bent, and welded, steel round bars offer a wide range of options for designing various decorative patterns. They possess durability and strength, making them suitable for both indoor and outdoor uses. Decorative furniture, sculptures, railings, gates, light fixtures, and many other items can be crafted from steel round bars. Their sleek and contemporary appearance adds an industrial and modern touch to any space. Furthermore, steel round bars can be finished with different coatings or treatments, such as powder coating or patina, to enhance their visual appeal and protect against corrosion. Consequently, steel round bars are an exceptional choice for creating decorative items because of their versatility, strength, and ability to infuse a stylish and distinctive element into any design.

- Q: What is the difference between a peeled and a centerless ground steel round bar?

- A peeled steel round bar refers to a process where the outer surface of the bar is removed, typically by using a peeling machine, to achieve a smooth and precise surface finish. This process helps to remove any imperfections or scale on the surface of the bar, resulting in a clean and polished appearance. The peeled round bar also undergoes a sizing process to ensure its dimensional accuracy, making it suitable for various applications where a smooth surface finish and precise dimensions are important. On the other hand, a centerless ground steel round bar refers to a process where the bar is ground using a centerless grinding machine. This process involves feeding the bar through grinding wheels that rotate at different speeds, removing material from the bar's outer diameter to achieve the desired size and surface finish. Centerless grinding allows for tight tolerances and precise sizing, making it suitable for applications that require high precision and accuracy. In summary, the main difference between a peeled and a centerless ground steel round bar lies in the process used to achieve the desired surface finish and dimensional accuracy. While both processes result in a smooth and precise bar, peeling removes material from the outer surface, whereas centerless grinding removes material from the outer diameter. The choice between the two depends on the specific requirements of the application and the desired surface finish and dimensional accuracy.

- Q: What are the typical dimensions of a steel round bar?

- The dimensions of a steel round bar can vary depending on the specific application and industry requirements. Generally, diameter sizes for steel round bars range from 1/4 inch to 24 inches. These sizes are often measured in increments of 1/8 inch or 1/4 inch. The length of a steel round bar is usually standardized at 20 feet, although shorter lengths may also be available. It is important to consider that these dimensions can significantly differ based on the grade and type of steel used, as well as the manufacturing process. Therefore, it is crucial to refer to the appropriate industry standards or consult a supplier for precise dimensions required for a particular project.

- Q: Can steel round bars be used in the production of gears?

- Yes, steel round bars can be used in the production of gears. Steel round bars are often used as a raw material in gear manufacturing due to their high strength, durability, and ability to withstand heavy loads and high temperatures. The round bars can be machined or forged into the desired gear shape, ensuring precise dimensions and accurate teeth profiles. Steel round bars also offer excellent wear resistance and can be heat-treated to further enhance their mechanical properties, making them a suitable choice for various types of gears, including spur gears, helical gears, bevel gears, and worm gears.

- Q: What are the standard sizes of steel round bars?

- The standard sizes of steel round bars vary depending on the country and the specific industry standards. In general, steel round bars are available in a wide range of diameters, typically ranging from 6mm (0.24 inches) to 400mm (15.75 inches) or even larger. Commonly used sizes for commercial applications include 10mm (0.39 inches), 12mm (0.47 inches), 16mm (0.63 inches), 20mm (0.79 inches), 25mm (0.98 inches), and 32mm (1.26 inches). However, it is important to note that these sizes may differ in different regions and industries, and specialized applications may require unique dimensions. It is always recommended to consult the relevant industry standards or consult with suppliers to determine the specific standard sizes for steel round bars in a particular context.

Send your message to us

Hot Rolled Prime Low Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords