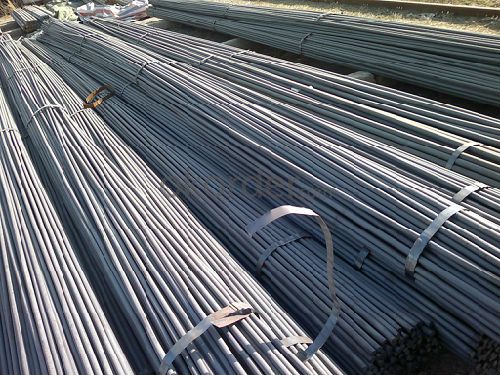

Hot Rolled Carbon Steel Round Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Round Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

1. Hot rolled round bar of 6-25mm, or small round is mostly used for straight bundles supply, and used for steel, bolts and various mechanical parts. While the bigger round bar, or more than 25mm hot rolled bar, is mainly for the manufacture of mechanical parts or for seamless steel billet.

2. Besides, we can supply some especial material steel round bar that can be used for main shaft of steamer, hummer shank, with big section and supper force.

Product Advantages:

OKorder's Round Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Grade: Q195, Q235, Q345

2. Diameter: 6mm-150mm

3. Length: 6m, 9m, 12m or as customer’s request

4. Tolerance: Within ±5% for weight; ±2mm for diameter

5. Note: The price can be better is the quantity is good

6. Chemical composition

Alloy No | Element (%) | ||||

C | Mn | S | P | Si | |

Q195 | 0.06-0.12 | 0.25 | ≤0.05 | ≤0.045 | ≤0.3 |

Q235 | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Q345 | ≤0.2 | 1.00-1.60 | ≤0.045 | ≤0.045 | ≤0.55 |

Production Flow of Round Bar

1. The common processes are preheated forging quenching, dual refinement solution process, cooling quenching and isothermal quenching. We use heat treatment for dual refinement solution process.

2. Material prepare (billet) — heat up — rough rolling — precision rolling — cooling — packing — storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Images:

- Q: How do steel round bars compare to aluminum round bars?

- Steel round bars are generally stronger and more durable than aluminum round bars. They have a higher tensile strength, making them suitable for heavy-duty applications that require high levels of strength and resistance to bending or deformation. Aluminum round bars, on the other hand, are lighter and more corrosion-resistant, making them ideal for applications that prioritize weight reduction and resistance to exposure to harsh environments. The choice between steel and aluminum round bars ultimately depends on the specific requirements of the application.

- Q: Can steel round bars be used for making bearings?

- Making bearings can indeed involve the use of steel round bars. However, it is crucial to acknowledge that the suitability of steel round bars for bearing applications relies heavily on the specific type of steel utilized and the manufacturing process employed. Bearings commonly encounter high loads and necessitate qualities such as good wear resistance, low friction, and high durability. For this reason, steel round bars made from top-notch alloy steels, such as chrome steel or stainless steel, are frequently employed in bearing production due to their exceptional mechanical properties. These steel round bars undergo particular heat treatment procedures, such as quenching and tempering, to enhance their hardness, strength, and wear resistance. Moreover, the round bars are usually machined with precise tolerances to ensure proper fit and alignment within the bearing assembly. To guarantee the most optimal performance, reliability, and longevity of bearings under various operating conditions, it is essential to seek advice from materials and manufacturing experts or consult industry standards. This will ensure the appropriate selection of steel round bar material and manufacturing processes for bearing applications.

- Q: What are the different surface finishes available for steel round bars?

- Steel round bars can be finished in various ways, each with its unique properties and applications. Some commonly used surface finishes include: 1. Hot Rolled: By heating the steel above its recrystallization temperature and allowing it to cool, a rough and scaled surface is achieved. This finish is suitable for applications that prioritize functionality over aesthetics. 2. Cold Drawn: The steel round bar is pulled through a die at room temperature, resulting in a smooth and polished surface. This finish offers improved dimensional accuracy and tight tolerances, making it ideal for precise applications that require a visually appealing appearance. 3. Turned and Polished: Using a lathe machine, the steel round bar is turned to achieve a smooth and shiny surface. This process eliminates any imperfections and irregularities, providing a close tolerance and highly finished surface. Turned and polished bars are commonly used in applications that demand high surface finish and dimensional accuracy, such as shafts and precision components. 4. Ground: Grinding is employed to remove surface defects and irregularities, resulting in a highly accurate and smooth surface finish. This finish is suitable for applications that require close tolerances and a superior surface finish, such as bearings, gears, and high-precision components. 5. Coated: Steel round bars can be coated with materials like zinc, chrome, or nickel to enhance their performance and protect against corrosion. Coated bars offer improved durability, corrosion resistance, and aesthetic appeal. The choice of surface finish for steel round bars depends on specific application requirements, including dimensional accuracy, surface quality, corrosion resistance, and aesthetic appeal.

- Q: Are steel round bars susceptible to corrosion?

- Yes, steel round bars are susceptible to corrosion.

- Q: How do you determine the straightness of a steel round bar?

- To determine the straightness of a steel round bar, there are several methods that can be used. One common method is visual inspection, where the bar is carefully examined for any visible bends, twists, or deviations from a straight line. This can be done by placing the bar on a flat surface and checking for any gaps or unevenness between the surface and the bar. Another method is to use a straightedge or a precision ruler. By placing the straightedge or ruler along the length of the bar, any deviations from a straight line can be easily detected. This method allows for more precise measurements and can help identify even slight bends or curves. Measuring devices such as dial indicators or laser alignment tools can also be used to determine the straightness of a steel round bar. These devices provide more accurate measurements and can quantify the degree of straightness by providing numerical readings of any deviations from a straight line. It is important to note that the acceptable level of straightness may vary depending on the specific application or industry standards. In such cases, specific tolerances or guidelines may need to be followed to ensure that the steel round bar meets the required straightness criteria. Overall, determining the straightness of a steel round bar requires careful visual inspection and the use of appropriate measuring tools to ensure that it meets the necessary straightness standards for its intended use.

- Q: Can steel round bars be used for making power transmission systems?

- Yes, steel round bars can be used for making power transmission systems. Steel round bars possess high strength and durability, making them suitable for transmitting power in various applications such as gears, shafts, and couplings.

- Q: What are the typical dimensions of a steel round bar?

- The dimensions of a steel round bar can vary depending on the specific application and industry requirements. Generally, diameter sizes for steel round bars range from 1/4 inch to 24 inches. These sizes are often measured in increments of 1/8 inch or 1/4 inch. The length of a steel round bar is usually standardized at 20 feet, although shorter lengths may also be available. It is important to consider that these dimensions can significantly differ based on the grade and type of steel used, as well as the manufacturing process. Therefore, it is crucial to refer to the appropriate industry standards or consult a supplier for precise dimensions required for a particular project.

- Q: How do steel round bars compare to wrought iron bars?

- Steel round bars and wrought iron bars have several differences that set them apart. Firstly, steel round bars are made from an alloy of iron and carbon, whereas wrought iron bars are composed of pure iron with a low carbon content. This difference in composition leads to varying properties. Steel round bars are known for their strength and durability, making them suitable for a wide range of applications, including construction, manufacturing, and engineering. On the other hand, wrought iron bars are softer and more malleable, allowing them to be easily shaped and formed into intricate designs. This characteristic makes wrought iron bars popular in decorative applications such as gates, fences, and ornamental pieces. Another difference lies in their manufacturing processes. Steel round bars are typically produced through hot rolling, which involves heating the steel billet and passing it through a series of rollers to shape it into the desired round bar form. In contrast, wrought iron bars are made through a labor-intensive process called blacksmithing. This involves heating the iron and repeatedly hammering it to remove impurities and create a fibrous structure, resulting in its characteristic grainy appearance. In terms of cost, steel round bars are generally more affordable compared to wrought iron bars. The manufacturing process for steel is more streamlined and efficient, leading to lower production costs. Wrought iron bars, on the other hand, require more time and labor, making them more expensive. Finally, when it comes to corrosion resistance, steel round bars have an advantage. Steel can be further alloyed with elements such as chromium, nickel, and molybdenum to enhance its resistance to rust and corrosion. This makes steel round bars suitable for outdoor applications where they may be exposed to moisture and harsh environmental conditions. Wrought iron bars, although they possess some level of corrosion resistance, are more prone to rusting and require regular maintenance to prevent deterioration. In conclusion, steel round bars and wrought iron bars differ in terms of composition, strength, manufacturing process, cost, and corrosion resistance. The choice between the two will depend on the specific requirements of the application, with steel round bars being favored for their strength and affordability, while wrought iron bars are often chosen for their malleability and decorative appeal.

- Q: What are the standard sizes of steel round bars?

- The standard sizes of steel round bars vary, but common diameters range from 1/4 inch to 12 inches.

- Q: What is the typical lead time for manufacturing steel round bars?

- The typical lead time for manufacturing steel round bars can vary depending on several factors, such as the quantity and size of the bars, the complexity of the manufacturing process, and the availability of raw materials. However, a general estimate for lead time could range from a few weeks to a couple of months. It is always best to consult with the specific manufacturer for an accurate timeframe.

Send your message to us

Hot Rolled Carbon Steel Round Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords