Hot Rolled Round Steel C45 Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

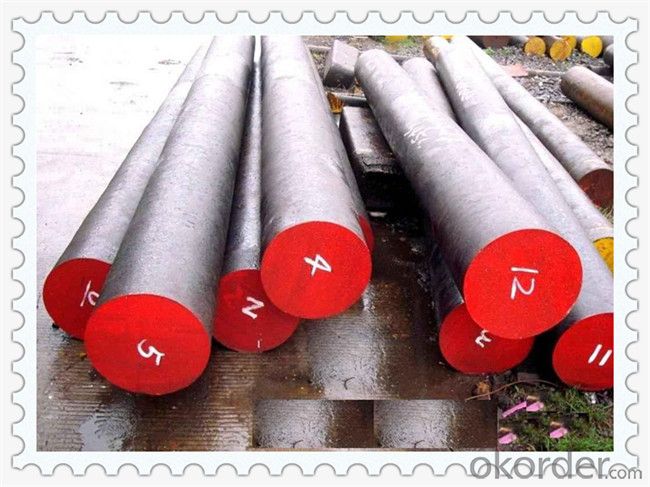

Hot Rolled Round Steel C45 Bars

Technical Paramenters

1. Chemical Composition(%)

C | Si | Mn | P | S | Cr | Ni | Cu | Al |

0.4~0.5 | 0.2~0.3 | 0.6~0.7 | ≤0.016 | ≤0.008 | ≤0.023 | ≤0.014 | 0.018 | ≤0.005 |

2. Comparable steel

GB | DIN | JIS | AISI |

45# | 1.1191 | S45C | 1045 |

3.Delivery Condition

Hor-rolled,black surface Hardness: ≤229HB.

4. Size Specification

Round Steel:Diameter:60~300mm; Length:2000~5800mm

Plate/Sheet Steel:Thickness:20-300MM;Width:200~2200mm;

Length:2000~5800mm

(We also can produce according to customer’s requirement)

5. Material character

Usually use for injection plastic mould, mould frame and some middle-range machine.

6. Application

Used for making the mould bottom, plastic mould and normal machinery parts

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: Can steel round bars be used in the production of forgings?

- Yes, steel round bars can be used in the production of forgings. Steel round bars are commonly used as raw materials for forging processes. The round bars are heated to a specific temperature and then shaped using various forging techniques such as hammering, pressing, or rolling. The heat and pressure applied during the forging process help to enhance the mechanical properties of the steel, making it stronger and more durable. Steel round bars are ideal for producing forgings as they provide a consistent and uniform shape, ensuring the final product meets the required specifications. Additionally, steel round bars offer versatility in terms of size, grade, and composition, allowing for a wide range of applications in various industries such as automotive, aerospace, and construction.

- Q: Can steel round bars be used for making electrical system components?

- Yes, steel round bars can be used for making electrical system components. Steel is a versatile material that has many applications in various industries, including electrical engineering. While other materials like copper are commonly used for electrical components due to their high electrical conductivity, steel can still be utilized for certain parts of an electrical system. Steel round bars can be used to manufacture structural components, supports, enclosures, or mounting brackets for electrical devices. Additionally, steel's durability, strength, and resistance to corrosion make it a suitable choice for electrical system components that require robust construction or protection from environmental factors. However, it is important to note that steel is not a good conductor of electricity compared to materials like copper or aluminum, so it may not be suitable for components that require high electrical conductivity.

- Q: What are the typical dimensions of a steel round bar?

- The typical dimensions of a steel round bar can vary depending on the specific application and industry requirements. However, in general, steel round bars are commonly available in diameter sizes ranging from 1/4 inch to 24 inches. These dimensions are often measured in increments of 1/8 inch or 1/4 inch. The length of a steel round bar is typically standardized at 20 feet, although shorter lengths may also be available. It is important to note that these dimensions can vary significantly depending on the specific grade and type of steel being used, as well as the manufacturing process. Therefore, it is essential to consult the appropriate industry standards or consult with a supplier to determine the exact dimensions needed for a particular project.

- Q: What are the cost considerations for steel round bars?

- The cost of steel round bars can vary depending on several factors. Firstly, the cost can be greatly influenced by the type and grade of steel used in production. Different types of steel, such as carbon steel, alloy steel, or stainless steel, have varying costs due to differences in their composition and properties. Higher grade steel, which offers superior strength and durability, tends to be more expensive compared to lower grade options. Secondly, the cost is affected by the size and dimensions of the round bars. Larger diameter and length of the bars require more raw material and additional processing, resulting in higher costs. Moreover, specialized shapes or custom sizes may necessitate extra manufacturing steps or tooling, which can increase the overall price. The quantity or volume of round bars ordered can also impact the cost. Bulk orders typically benefit from economies of scale, leading to reduced unit costs. Additionally, longer-term contracts or partnerships with suppliers can result in better pricing agreements. It is important to consider transportation and logistics expenses as well. The cost of shipping steel round bars can vary based on factors such as distance, mode of transportation, and handling requirements. International shipping, for example, may involve additional customs duties and taxes. Lastly, market conditions and fluctuations in the steel industry can have an impact on the cost of round bars. Factors like supply and demand, raw material costs, and currency exchange rates can all influence the final price. It is crucial to stay updated with market trends and work closely with suppliers to negotiate favorable pricing. To ensure that the cost of steel round bars aligns with your budget and meets your specific requirements, it is essential to conduct thorough research, compare quotes from multiple suppliers, and evaluate the quality-to-price ratio before making a decision.

- Q: What are the different types of steel round bars used in the manufacturing of valves and fittings?

- There are several different types of steel round bars commonly used in the manufacturing of valves and fittings. These include: 1. Carbon Steel Round Bars: Carbon steel round bars are the most commonly used type of steel in valve and fitting manufacturing. They are known for their strength, durability, and ability to withstand high temperatures and pressures. 2. Stainless Steel Round Bars: Stainless steel round bars are highly resistant to corrosion, making them ideal for use in valves and fittings that come into contact with liquids or gases. They are also known for their high strength and excellent mechanical properties. 3. Alloy Steel Round Bars: Alloy steel round bars are made by adding various alloying elements such as chromium, manganese, and nickel to carbon steel. This enhances their strength, hardness, and resistance to wear and tear, making them suitable for use in demanding valve and fitting applications. 4. Duplex Steel Round Bars: Duplex steel round bars are a type of stainless steel that contains a balanced mix of ferrite and austenite phases. This gives them a unique combination of excellent strength, corrosion resistance, and resistance to stress corrosion cracking, making them suitable for use in valves and fittings exposed to harsh environments. 5. Nickel Alloy Round Bars: Nickel alloy round bars are known for their exceptional resistance to corrosion and high-temperature applications. They offer excellent mechanical properties and are commonly used in valves and fittings that handle corrosive fluids or operate in extreme temperatures. It is important to select the appropriate type of steel round bar for valve and fitting manufacturing based on the specific requirements of the application, considering factors such as pressure, temperature, fluid compatibility, and environmental conditions.

- Q: What are the tolerance levels for steel round bars?

- Steel round bars have varying tolerance levels depending on the specific application and industry standards. To ensure precision in terms of diameter, straightness, and surface finish, steel round bars are typically produced with tight dimensional tolerances. Diameter tolerances specify the acceptable range of deviation from the nominal diameter of the round bar and are expressed as a plus or minus value, such as +/- 0.005 inches. The specific tolerance depends on the size, type of steel round bar, and application requirements. Straightness tolerances determine the allowable amount of deviation from a perfectly straight line along the length of the round bar. This tolerance is expressed as the maximum distance between the round bar and a straight edge placed along its length. For instance, a straightness tolerance of 0.030 inches per foot means that a one-foot section of the round bar can deviate up to 0.030 inches from a straight line. Surface finish tolerances specify the acceptable level of imperfections or irregularities on the surface of the round bar. This tolerance is often expressed using roughness average (Ra) or roughness peak (Rz) values. The specific tolerance depends on the desired surface finish and application requirements. It is worth noting that tolerance levels may also be subject to industry-specific standards established by organizations like the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). These standards provide guidelines and specifications for various steel products, including round bars, to ensure consistent quality and performance. Ultimately, determining the tolerance levels for steel round bars involves considering the specific application requirements, industry standards, and the capabilities of the manufacturing process.

- Q: How do steel round bars contribute to sustainable construction?

- Steel round bars contribute to sustainable construction in several ways. Firstly, steel is a highly durable and long-lasting material, which means that structures built using steel round bars have a longer lifespan and require less maintenance and repairs over time. This reduces the need for frequent replacement, thereby conserving resources and reducing waste. Secondly, steel is a recyclable material, and steel round bars can be easily recycled and reused in other construction projects. By promoting the use of recycled steel, we can reduce the demand for raw materials and minimize the environmental impact associated with steel production. Additionally, steel round bars offer excellent structural strength and flexibility, allowing for more efficient designs and optimized use of materials. This results in lighter and more sustainable structures that require fewer resources to construct. Lastly, steel round bars are often used in reinforced concrete structures, which can enhance the durability and seismic resistance of buildings. By utilizing steel reinforcement, we can ensure the longevity and safety of structures, reducing the need for reconstruction and enhancing the resilience of our built environment. Overall, steel round bars contribute to sustainable construction by promoting durability, recyclability, resource efficiency, and improved structural performance in buildings and infrastructure projects.

- Q: Are steel round bars used in the automotive industry?

- Steel round bars are widely utilized in the automotive industry. They find their application in diverse areas like the production of engine components, suspension systems, chassis, and axles. Due to their exceptional strength, durability, and versatility, steel round bars are highly favored for automotive parts that demand exceptional performance and reliability. Moreover, steel's capacity to endure heavy loads and its resistance to deformation make it well-suited for critical automotive applications prioritizing safety.

- Q: Are lightning checks required for galvanized steel, flat steel and round steel?

- No, when purchasing hot galvanized round steel and flat steel, please offer the factory certificate and inspection certificate.

- Q: Can steel round bars be used in the marine industry?

- Steel round bars are indeed suitable for use in the marine industry. Steel is highly favored in this industry because of its exceptional strength, durability, and resistance to corrosion. In the marine industry, steel round bars find widespread use in a variety of applications. These applications include the construction of ship hulls, the fabrication of offshore structures, the production of marine equipment and components, and the development of mooring systems. Steel round bars are capable of enduring the harsh conditions of the marine environment, including exposure to saltwater, waves, and extreme weather conditions. Furthermore, steel round bars possess the advantage of being easily manipulated, welded, and machined, rendering them an adaptable choice for marine applications.

Send your message to us

Hot Rolled Round Steel C45 Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords