Hot Rolled Round Steel Bars C45

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Round Steel Bars C45

Technical Paramenters

1. Chemical Composition(%)

C | Si | Mn | P | S | Cr | Ni | Cu | Al |

0.4~0.5 | 0.2~0.3 | 0.6~0.7 | ≤0.016 | ≤0.008 | ≤0.023 | ≤0.014 | 0.018 | ≤0.005 |

2. Comparable steel

GB | DIN | JIS | AISI |

45# | 1.1191 | S45C | 1045 |

3.Delivery Condition

Hor-rolled,black surface Hardness: ≤229HB.

4. Size Specification

Round Steel:Diameter:60~300mm; Length:2000~5800mm

Plate/Sheet Steel:Thickness:20-300MM;Width:200~2200mm;

Length:2000~5800mm

(We also can produce according to customer’s requirement)

5. Material character

Usually use for injection plastic mould, mould frame and some middle-range machine.

6. Application

Used for making the mould bottom, plastic mould and normal machinery parts

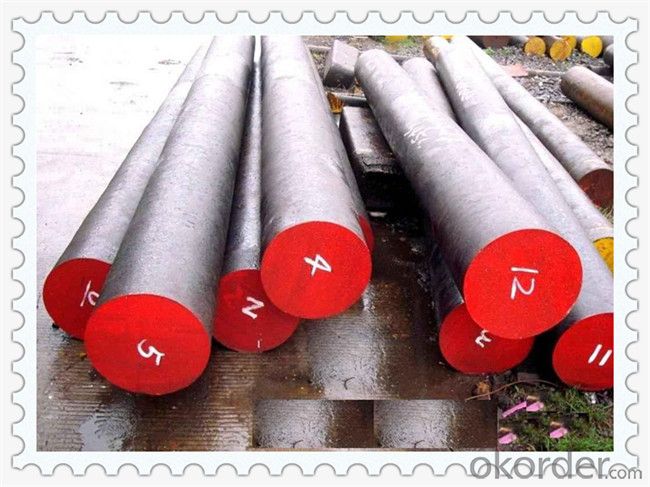

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What are the advantages of using zinc-alloy steel round bars?

- One of the advantages of using zinc-alloy steel round bars is their high corrosion resistance. The zinc coating acts as a protective barrier, preventing rust and corrosion, which makes these bars suitable for outdoor applications and environments with high humidity. Additionally, zinc-alloy steel round bars have excellent strength and durability, making them ideal for structural and load-bearing purposes. Furthermore, the zinc coating provides enhanced aesthetics, offering a polished and visually appealing finish. Overall, the advantages of using zinc-alloy steel round bars include corrosion resistance, strength, durability, and improved appearance.

- Q: What is the elongation of a steel round bar?

- The elongation of a steel round bar refers to the amount of lengthening or stretching the bar undergoes when subjected to an applied force or load.

- Q: How are steel round bars manufactured?

- Hot rolling is the method utilized to produce steel round bars. The process begins with heating a large steel billet in a furnace until it becomes soft and malleable. Subsequently, the billet is passed through a series of rollers, which compress and shape it into a round bar. The initial step in hot rolling is the roughing mill, where the billet is subjected to multiple sets of rollers to reduce its thickness and increase its length. This step ensures that the steel maintains a consistent temperature throughout. Following the roughing mill, the bar enters the finishing mill, where it undergoes further size reduction and acquires its final shape. The finishing mill typically comprises several sets of rollers that gradually decrease the bar's diameter while increasing its length. This process is repeated until the desired dimensions are attained. Throughout the rolling process, rigorous quality control measures are implemented to continuously monitor the steel round bar. Any imperfections or defects that arise are promptly identified and rectified to ensure the final product adheres to the required specifications. Once the bar reaches its final dimensions, it is cooled and cut to the desired length. The cooling process can be achieved through the use of air, water, or a combination of both. Subsequently, the bar is inspected for any surface defects and may undergo further processing if needed. In certain cases, additional treatments such as heat treatment or surface finishing may be employed to enhance the properties and appearance of the steel round bar. In conclusion, the manufacturing of steel round bars involves a combination of heating, rolling, cooling, and cutting processes. These procedures are meticulously executed to yield a superior product that fulfills the specific requirements of diverse industries.

- Q: How do you measure the length of a steel round bar?

- To measure the length of a steel round bar, you can use a measuring tape or a ruler. Simply place one end of the measuring tool at the starting point of the bar, and extend it until you reach the other end. Ensure that the measuring tool is aligned correctly with the bar for an accurate measurement.

- Q: What are the different types of steel round bars used in the manufacturing of tools?

- There are several different types of steel round bars that are commonly used in the manufacturing of tools. Each type of steel has its own unique properties and characteristics that make it suitable for different applications. Here are some of the most common types of steel round bars used in tool manufacturing: 1. Carbon Steel Round Bars: These are the most commonly used type of steel round bars in tool manufacturing. They are known for their high strength and durability, making them ideal for heavy-duty applications. Carbon steel round bars can be further classified into low carbon, medium carbon, and high carbon steel, depending on the amount of carbon content present. 2. Alloy Steel Round Bars: Alloy steel round bars are made by adding various alloying elements such as manganese, chromium, nickel, or molybdenum to carbon steel. This results in enhanced strength, hardness, and resistance to wear and tear. Alloy steel round bars are commonly used in the manufacturing of cutting tools, drills, and gears. 3. Stainless Steel Round Bars: Stainless steel round bars are known for their corrosion resistance and high tensile strength. They are commonly used in the manufacturing of tools that require resistance to rust, such as kitchen knives, surgical instruments, and automotive components. 4. Tool Steel Round Bars: Tool steel round bars are specifically designed to be used in the manufacturing of tools, hence the name. They have high hardness, wear resistance, and toughness, making them ideal for applications such as cutting, drilling, and shaping. Tool steel round bars can be further classified into several types based on their specific properties, such as high-speed steel (HSS), cold work steel, hot work steel, and shock-resistant steel. 5. Stainless Tool Steel Round Bars: Stainless tool steel round bars combine the characteristics of stainless steel and tool steel. They offer good resistance to corrosion and wear, making them suitable for applications where both properties are required, such as in the manufacturing of molds and dies. These are just a few examples of the different types of steel round bars used in tool manufacturing. The choice of steel depends on the specific requirements of the tool and the application it will be used for.

- Q: How are steel round bars used in the manufacturing of hydraulic systems?

- Steel round bars are commonly used in the manufacturing of hydraulic systems due to their strength, durability, and versatility. These bars serve various purposes in the construction and assembly of hydraulic components. One primary use of steel round bars in hydraulic systems is for the fabrication of piston rods. Piston rods are crucial components of hydraulic cylinders, responsible for transferring the force generated by the hydraulic fluid to the desired mechanism. The high strength and rigidity of steel round bars make them ideal for this application, as they can withstand the intense pressure and stress exerted on the piston rod during operation. Steel round bars are also utilized in the manufacturing of shafts and axles within hydraulic systems. These components are responsible for transmitting rotational motion and torque from the hydraulic pump to other mechanical parts, such as gears or pulleys. By using steel round bars, manufacturers can ensure the reliability and longevity of these critical parts, as they possess excellent mechanical properties and resistance to wear and tear. Additionally, steel round bars are often employed in the construction of hydraulic fittings and connectors. These components are responsible for joining different hydraulic pipes, hoses, or valves together, creating a sealed system for fluid transmission. Steel round bars provide the necessary strength and stability to withstand the high-pressure conditions within hydraulic systems, ensuring leak-free operation and the efficient transfer of fluids. In summary, steel round bars play a vital role in the manufacturing of hydraulic systems by providing strength, durability, and versatility. Their use in piston rods, shafts, axles, fittings, and connectors ensures the proper functioning and reliability of these systems.

- Q: How are steel round bars tested for quality and compliance?

- Steel round bars are tested for quality and compliance through a series of rigorous tests and inspections to ensure they meet the required standards and specifications. One of the most common tests used is the tensile test, which measures the bar's ability to withstand pulling forces. This test involves stretching the bar until it breaks and analyzing the stress-strain curve to determine its mechanical properties, such as yield strength, ultimate tensile strength, and elongation. Another important test is the hardness test, which measures the resistance of the bar's surface to indentation. This test helps determine the material's strength and its ability to resist wear and deformation. Chemical analysis is also conducted to verify the composition of the steel round bars. This test determines the percentage of elements present in the steel, such as carbon, manganese, silicon, sulfur, and phosphorus. It ensures that the steel is made according to the required specifications and is suitable for the intended application. Dimensional inspection is crucial to ensure that the steel round bars meet the specified dimensions and tolerances. This involves measuring the length, diameter, and straightness of the bars using calibrated instruments. Surface quality is assessed through visual inspection and non-destructive testing methods, such as ultrasonic testing and magnetic particle inspection. These tests detect any surface defects, cracks, or discontinuities that may affect the bar's performance and integrity. In addition to these tests, steel round bars may undergo other specialized tests based on their intended application. For example, bars used in the construction industry may be subjected to corrosion resistance or impact testing. Overall, the quality and compliance of steel round bars are ensured through a comprehensive range of tests, inspections, and analyses. These tests help manufacturers and customers determine the suitability and reliability of the bars for specific applications, ensuring the safety and effectiveness of the final products.

- Q: Are steel round bars suitable for the production of gears?

- Yes, steel round bars are suitable for the production of gears. Steel is a common material used in gear manufacturing due to its high strength, durability, and resistance to wear and tear. The round bar shape allows for easy machining and shaping of the gear teeth. Steel round bars also provide excellent hardness and toughness, ensuring that the gears can withstand heavy loads and operate smoothly. Additionally, steel can be heat treated to further enhance its mechanical properties, making it an ideal choice for gear production.

- Q: What are the advantages of using carbon-manganese alloy steel round bars?

- Carbon-manganese alloy steel round bars offer several advantages. Firstly, they possess excellent strength and durability, making them ideal for applications requiring high mechanical properties. Additionally, the presence of manganese enhances the hardenability of the steel, allowing it to be easily heat-treated to achieve desired hardness levels. Moreover, carbon-manganese alloy steel round bars exhibit good weldability and machinability, making them versatile and easy to work with. Lastly, they provide cost advantages as they are relatively affordable compared to other high-strength steel options.

- Q: What are the different types of steel round bars used in the manufacturing of cutting tools?

- In the manufacturing of cutting tools, there are various types of steel round bars commonly used. These include: 1. High-Speed Steel (HSS): HSS round bars possess exceptional hardness, wear resistance, and the ability to maintain a sharp cutting edge even at high temperatures. They find extensive use in metalworking and high-speed applications for the production of drills, end mills, and other cutting tools. 2. Tool Steel: Tool steel round bars are widely utilized in cutting tool production due to their high strength, toughness, and resistance to wear and deformation. Different grades of tool steel, such as D2, A2, and O1, are selected based on the specific requirements and applications of the cutting tool. 3. Carbon Steel: Cutting tools designed for softer materials like wood and plastics often incorporate carbon steel round bars. Carbon steel offers satisfactory hardness and durability, making it suitable for a wide range of cutting applications. 4. Stainless Steel: Cutting tools requiring superior corrosion resistance and strength often employ stainless steel round bars. Stainless steel provides good durability, toughness, and edge retention, making it a popular choice in industries such as food, medicine, and other cleanliness-sensitive applications. 5. Alloy Steel: The production of alloy steel round bars involves the addition of various alloying elements like chromium, molybdenum, and vanadium to enhance its properties. Alloy steel exhibits improved hardness, strength, and wear resistance, making it suitable for demanding cutting applications like machining hardened materials and high-temperature cutting. Choosing the appropriate type of steel round bar for a cutting tool is crucial and depends on specific requirements such as the material being cut, desired cutting speed, and expected operating conditions.

Send your message to us

Hot Rolled Round Steel Bars C45

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords