C35 Carbon Steel Round Bar C35 Hot Rolled Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

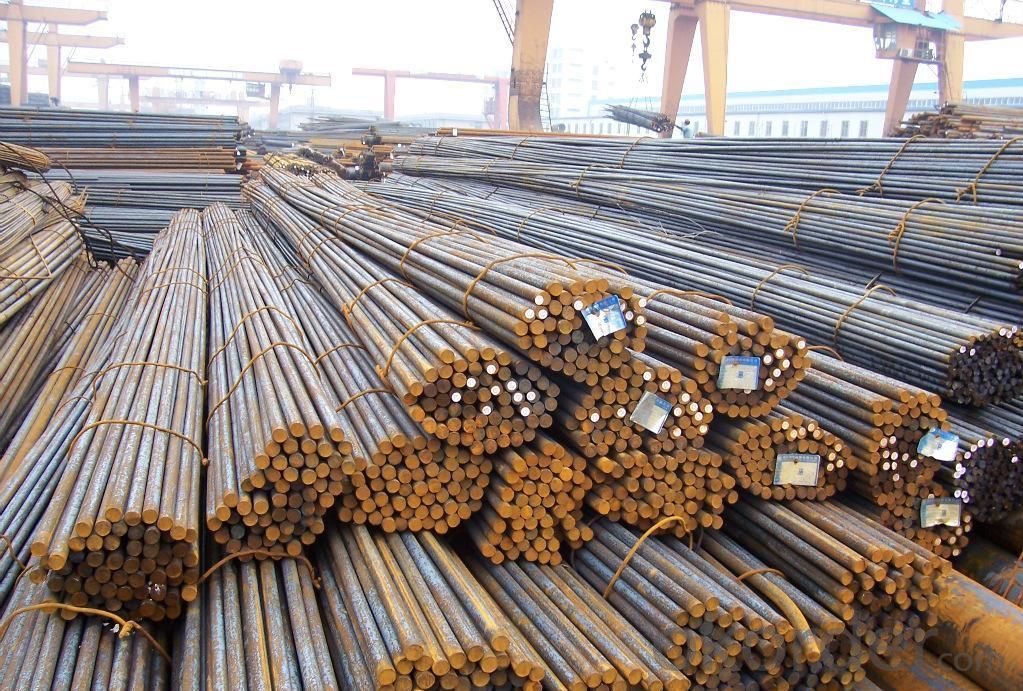

C35 Carbon Steel Round Bar C35 Hot Rolled Bars

Product Description:

1. Sizes: Diameter: 16mm-300mm; Length: 6m, 9m, 12m

2. Grade: 35#, SAE1035, S35C, C35

3. Invoicing on theoretical weight or actual weight as customer’s request

4. Shape: Round bar, solid bar of steel with circular section

5. Technique: Hot rolled, forged, cold rolled

Chemical Composition:

C | Si | Mn | P | S | Ni | Cr | Cu |

0.32-0.40 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.25 | ≤0.25 |

Packing and Delivery:

Packing in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: Approx.45 days

Usage and Applications

1. C35 Carbon Steel Round Bar C35 Hot Rolled Bars is used in a large number of architectural and engineering structures. Or it can be used in construction of plants for the production of steel house frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Some especial material steel round bar can be used for main shaft of steamer, hummer shank, with big section and supper force.

Specification:

OD | Length | Material | Standard | Technique |

16-260mm | 6-12m or aques per request | 20# | GB ASTM DIN | Hot rolled |

16-350mm | 35# | |||

200-500mm | 35# | Forged | ||

20-250mm | 20Cr,40Cr,20-42CrMo | Hot rolled | ||

50-300mm | GCr15 |

Main product pictures:

- Q: What are the different surface coating methods used for special steel?

- There are several surface coating methods that are commonly used for special steel to enhance its properties and protect it from various environmental factors. These methods include: 1. Galvanizing: This is a process in which a layer of zinc is applied to the surface of the steel. It provides excellent corrosion resistance and can be done through hot-dip galvanizing or electroplating. 2. Electroplating: In this method, a thin layer of metal such as chromium, nickel, or copper is deposited onto the steel surface through an electrochemical process. This improves the steel's appearance, wear resistance, and corrosion resistance. 3. Powder coating: Powder coating involves applying a dry powder to the steel surface, which is then heated and fused to form a protective layer. It provides excellent durability, weather resistance, and aesthetic appeal. 4. Thermal spray coating: This method involves spraying a molten or heated material onto the steel surface, which then solidifies to form a protective coating. Materials commonly used for thermal spray coating include metals, ceramics, and polymers. 5. Paint coating: Painting is a commonly used method for surface coating. Different types of paints, such as epoxy, polyurethane, or acrylic, can be applied to the steel surface to provide protection against corrosion, chemicals, and UV radiation. 6. PVD coating: Physical Vapor Deposition (PVD) is a process in which a thin film of a material, such as titanium nitride or diamond-like carbon, is deposited onto the steel surface through a vacuum deposition process. PVD coatings enhance hardness, wear resistance, and appearance. 7. Anodizing: Anodizing is primarily used for aluminum, but it can also be applied to special steel. This process involves creating an oxide layer on the steel surface through an electrochemical reaction, which improves corrosion resistance and adds a decorative finish. These surface coating methods are essential for special steel as they provide enhanced protection against corrosion, wear, and other environmental factors, thereby extending the lifespan and improving the performance of the steel. The choice of coating method depends on the specific requirements and desired properties of the steel.

- Q: Can special steel be used in marine environments?

- Indeed, marine environments can benefit from the utilization of special steel. Specifically engineered to endure the harsh conditions prevalent in marine settings, special steel, such as stainless steel or marine-grade steel, proves its worth. These environments typically expose materials to saltwater, which possesses a highly corrosive nature. Nonetheless, special steel's resistance to corrosion remains intact due to its elevated levels of chromium and other alloying elements. Consequently, it becomes exceedingly suitable for an array of marine applications, encompassing shipbuilding, offshore structures, and marine equipment. The reliability of special steel lies in its exceptional strength, durability, and corrosion resistance. Moreover, to further augment its resistance to corrosion, special steel can undergo additional treatment and coating, thereby guaranteeing its longevity and optimal performance in marine conditions.

- Q: Can special steel be used in the aerospace industry?

- Yes, special steel can be used in the aerospace industry. Special steel alloys, such as stainless steel and titanium alloys, possess excellent strength, corrosion resistance, and heat resistance properties required for aircraft components. These materials are commonly used in critical applications like engine parts, landing gears, and structural components to ensure high performance and safety in aerospace operations.

- Q: What are the different galvanizing techniques used for special steel?

- There are several galvanizing techniques used for special steel, including hot-dip galvanizing, electro-galvanizing, and mechanical galvanizing. Hot-dip galvanizing involves immersing the steel in a bath of molten zinc, creating a thick, durable coating. Electro-galvanizing, on the other hand, uses an electrical current to deposit a thin layer of zinc onto the steel surface. Mechanical galvanizing involves tumbling the steel in a zinc powder and glass bead mixture, which adheres to the surface through friction. Each technique has its own advantages and is used depending on the specific requirements of the application.

- Q: What are the main characteristics of alloy steel?

- The main characteristics of alloy steel include high strength, hardness, and durability due to the presence of different alloying elements such as manganese, nickel, chromium, and molybdenum. It also exhibits good resistance to corrosion, wear, and heat, making it suitable for various applications in industries such as automotive, aerospace, and construction. Additionally, alloy steel offers excellent machinability and weldability, allowing for ease of fabrication and customization.

- Q: How does spring steel maintain its elasticity?

- Spring steel maintains its elasticity due to its unique composition and manufacturing process. It is made from a high carbon steel alloy that undergoes heat treatment and quenching, which gives it its exceptional strength and flexibility. This heat treatment process called tempering allows the steel to retain its shape and bounce back to its original form after being deformed or subjected to external forces. The carbon content in spring steel also contributes to its elasticity by providing increased hardness and resistance to deformation. Overall, the combination of high carbon content, heat treatment, and quenching make spring steel highly durable and able to maintain its elasticity over extended periods of use.

- Q: Can special steel be used in the recycling industry?

- Yes, special steel can be used in the recycling industry. Special steel, which is highly durable and resistant to corrosion, can be recycled and reused in various applications. It can be melted down and reprocessed to create new steel products, reducing the need for raw materials and minimizing waste in the recycling industry.

- Q: How is carbon steel used in the manufacturing of pipes and tubes?

- Carbon steel is commonly used in the manufacturing of pipes and tubes due to its durability, strength, and cost-effectiveness. It is a versatile material that can withstand high temperatures and pressures, making it suitable for various applications such as oil and gas pipelines, water distribution systems, and structural supports. Additionally, carbon steel can be easily welded and fabricated, allowing for efficient production and customization of pipes and tubes to meet specific requirements.

- Q: How does special steel contribute to the transportation industry?

- Special steel plays a crucial role in the transportation industry by providing materials with enhanced strength, durability, and resistance to various environmental factors. This type of steel is used in the manufacturing of components and structures for vehicles, such as engines, axles, suspension systems, and body frames. Its high tensile strength allows for lighter and more fuel-efficient designs, while offering superior safety and performance. Additionally, special steel's corrosion resistance properties help prolong the lifespan of transportation equipment, reducing maintenance costs and enhancing overall reliability.

- Q: How does special steel contribute to the renewable energy storage?

- Special steel plays a crucial role in renewable energy storage by enabling the production of high-performance components for energy storage systems. It is used in the manufacturing of batteries, such as lithium-ion batteries, which are widely utilized in renewable energy storage applications. Special steel provides the necessary strength, durability, and resistance to corrosion, ensuring the longevity and efficiency of these batteries. Additionally, special steel is essential for the construction of renewable energy infrastructure, including wind turbines and solar panel frames, which require sturdy and reliable materials to withstand harsh environmental conditions. Therefore, special steel contributes significantly to the development and advancement of renewable energy storage solutions.

Send your message to us

C35 Carbon Steel Round Bar C35 Hot Rolled Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords