Grade SAE 4140 Steel Price_Steel Round Bar Dimension

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade SAE 4140 Steel Price_Steel Round Bar Dimension

Details of Grade SAE 4140 Steel Price_Steel Round Bar Dimension

Name | Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of SAE 4140 Steel Price_Steel Round Bar Dimension

1.Size of 4140 Steel Round Bar | ||||||||

Round bar | Diameter(mm) | Length (mm) | ||||||

20~800 | 3000~9000 | |||||||

Plate | Thickness(mm) | Width (mm) | Length (mm) | |||||

Max:800 | Max:2200 | Max:9000 | ||||||

The specification can be customized. | ||||||||

2.Chemical Compositons | ||||||||

Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

42CrMo | 0.38~0.45 | 0.17~0.37 | 0.50~0.8 | ≤0.035 | ≤0.035 | 0.9~1.2 | 0.15-0.25 | ≤0.3 |

4140 | 0.40~0.45 | 0.15~0.35 | 0.75~1.0 | ≤0.035 | ≤0.040 | 0.8~1.1 | 0.15-0.25 | - |

SCM44 | 0.38~0.43 | 0.15~0.35 | 0.60~0.9 | ≤0.030 | ≤0.030 | 0.9~1.2 | 0.15-0.30 | ≤0.25 |

1.7225 | 0.38~0.45 | ≤0.40 | 0.60~0.9 | ≤0.025 | ≤0.035 | 0.9~1.2 | 0.15-0.30 |

|

3.Features of 4140 alloy steel | ||||||||

1. Chromium molybdenum alloy steel | ||||||||

2. Slightly higher carbon content then 4130 | ||||||||

3. Greater strength and heat treatment | ||||||||

4.Typical Applications | ||||||||

1. Applications in the oil and gas sector | ||||||||

2. Connection rods, collets, conveyor pins, | ||||||||

3. Gears, stem assemblies, | ||||||||

4. Pump shafts and tool holders | ||||||||

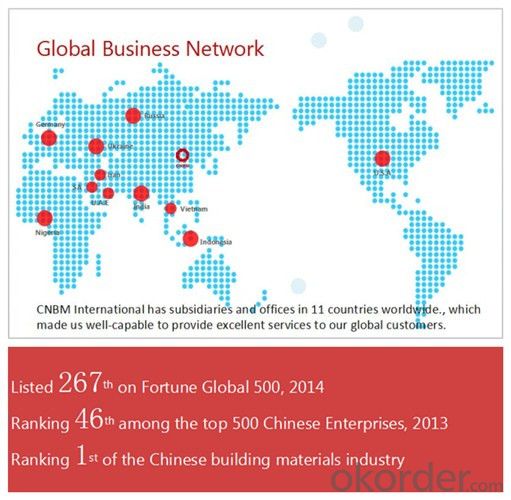

CNBM Introduction of SAE 4140 Steel Price_Steel Round Bar Dimension Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery SAE 4140 Steel Price_Steel Round Bar Dimension

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How is special steel used in the production of hydraulic components?

- Special steel is used in the production of hydraulic components due to its high strength, corrosion resistance, and ability to withstand extreme pressure and temperature conditions. It helps in manufacturing durable and reliable hydraulic parts such as cylinders, valves, fittings, and pistons, ensuring efficient functioning and long-lasting performance of hydraulic systems.

- Q: What are the different types of wear-resistant steel?

- There are several different types of wear-resistant steel, including AR400, AR500, Hardox, and Domex. These steels are specifically designed to withstand abrasion and provide excellent durability in applications where materials are subjected to constant wear and impact.

- Q: How does special steel contribute to the durability of products?

- There are several ways in which special steel enhances the durability of products. Initially, special steel's notable qualities of high strength and hardness make it resistant to wear and tear. As a result, products constructed from special steel can endure heavy usage and outlast those made from regular steel or alternative materials. Moreover, special steel commonly incorporates other elements like chromium, nickel, and molybdenum, which heighten its resistance to corrosion. This is particularly crucial for products exposed to harsh environments or chemicals. The corrosion resistance of special steel aids in preventing rust and deterioration, thus increasing the product's lifespan. Additionally, special steel can undergo heat treatment to enhance its mechanical properties, including toughness and hardness. Through specific heating and cooling processes, heat-treated special steel becomes stronger, rendering it less susceptible to deformation and breakage. This is especially advantageous for products subjected to heavy loads or impacts. Furthermore, special steel is often manufactured with precise composition and microstructure, resulting in improved material properties. This encompasses superior fatigue resistance, implying that the material can endure repeated stress without developing cracks or breaking. Consequently, products made from special steel exhibit enhanced reliability and are less prone to failure. In conclusion, special steel significantly contributes to product durability through its high strength, corrosion resistance, improved mechanical properties, and superior fatigue resistance. By incorporating special steel into the manufacturing process, products can be designed to withstand various demanding conditions, ensuring a longer lifespan and greater reliability.

- Q: What are the properties of high-speed tool steel?

- High-speed tool steel is known for its exceptional hardness, wear resistance, and ability to retain its cutting edge even at high temperatures. It also exhibits excellent toughness, strength, and dimensional stability, making it ideal for applications that involve high-speed machining, cutting, or drilling operations. Additionally, high-speed tool steel has good heat resistance and can withstand thermal shock, making it suitable for use in demanding industrial environments.

- Q: How does special steel contribute to the packaging aftermarket industry?

- The packaging aftermarket industry greatly benefits from the use of special steel, which provides various advantages that enhance the efficiency and quality of packaging processes. Firstly, special steel is renowned for its exceptional strength and durability, making it ideal for the manufacturing of packaging machinery and equipment. This durability ensures that the machinery can withstand the demanding requirements of the industry, resulting in improved reliability and less downtime. Additionally, special steel boasts excellent resistance to corrosion, making it highly suitable for packaging applications that involve exposure to moisture, chemicals, or extreme temperatures. This corrosion resistance extends the lifespan of packaging equipment and prevents degradation, ultimately reducing maintenance costs and enhancing the overall efficiency of the packaging aftermarket industry. Moreover, special steel can be customized to meet specific needs, allowing for the production of tailored packaging solutions. This flexibility and versatility enable manufacturers to create innovative designs that enhance product protection, optimize space utilization, and improve transportation logistics. For example, special steel can be used to manufacture lightweight yet strong packaging materials, reducing shipping costs and minimizing the environmental impact associated with packaging waste. Furthermore, special steel possesses excellent machinability and weldability, making it easy to fabricate intricate packaging components with high precision. This capability enables manufacturers to produce packaging solutions that perfectly fit specific product dimensions, ensuring optimal protection during transit. In conclusion, special steel plays a vital role in the packaging aftermarket industry by offering strength, durability, corrosion resistance, customization options, and excellent machinability. These qualities contribute to the overall efficiency, reliability, and quality of packaging processes, benefiting both manufacturers and consumers.

- Q: How does special steel contribute to the automotive aftermarket?

- Special steel contributes to the automotive aftermarket by providing high-performance and durable components that enhance the overall performance, safety, and reliability of vehicles. Special steel, such as high-strength steel and stainless steel, is used in the manufacturing of various automotive parts, including engine components, chassis, suspension systems, and exhaust systems. These materials offer superior strength, corrosion resistance, and heat resistance, thereby ensuring longer service life and improved performance of aftermarket automotive parts. Additionally, special steel enables the development of lightweight designs, leading to fuel efficiency improvements and reduced emissions, which are crucial factors in the automotive industry.

- Q: How does special steel perform in aerospace applications?

- Special steel performs exceptionally well in aerospace applications due to its unique properties. It possesses high strength, excellent corrosion resistance, and exceptional heat resistance, making it ideal for manufacturing critical components such as turbine blades, landing gear, and structural frameworks. The use of special steel ensures the durability and safety of aerospace systems, enabling them to withstand extreme conditions, such as high temperatures and pressure, encountered during flight.

- Q: How does special steel contribute to improved product aesthetics?

- Special steel contributes to improved product aesthetics in several ways. Firstly, special steel can be formulated to have a higher level of purity, resulting in a cleaner and more polished appearance. This enhances the overall visual appeal of the product. Additionally, special steel can be engineered to have unique surface finishes, such as brushed or mirror-like effects, which can add a sophisticated and luxurious touch to the product design. Furthermore, special steel can be shaped and molded with precision, allowing for intricate and intricate designs that enhance the aesthetics of the product. Overall, the use of special steel in manufacturing helps to elevate the visual appeal of products, making them more attractive and visually pleasing to consumers.

- Q: What are the applications of special steel in the oil and gas supply chain?

- Special steel is widely used in the oil and gas supply chain due to its exceptional properties. It is used for various applications such as pipes, valves, and fittings, where its high strength, corrosion resistance, and ability to withstand extreme temperatures and pressures are crucial. Special steel is also used in equipment like drilling tools, offshore platforms, and storage tanks, ensuring reliability and durability in challenging environments. Additionally, it is employed in the construction of pipelines, providing a reliable and safe mode of transportation for oil and gas products.

- Q: How does special steel perform in terms of thermal expansion?

- Special steel typically performs well in terms of thermal expansion. It has a low coefficient of thermal expansion, meaning it expands and contracts less with temperature changes compared to other types of steel. This makes it more dimensionally stable and less prone to warping or distortion when exposed to heat or cold.

Send your message to us

Grade SAE 4140 Steel Price_Steel Round Bar Dimension

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords