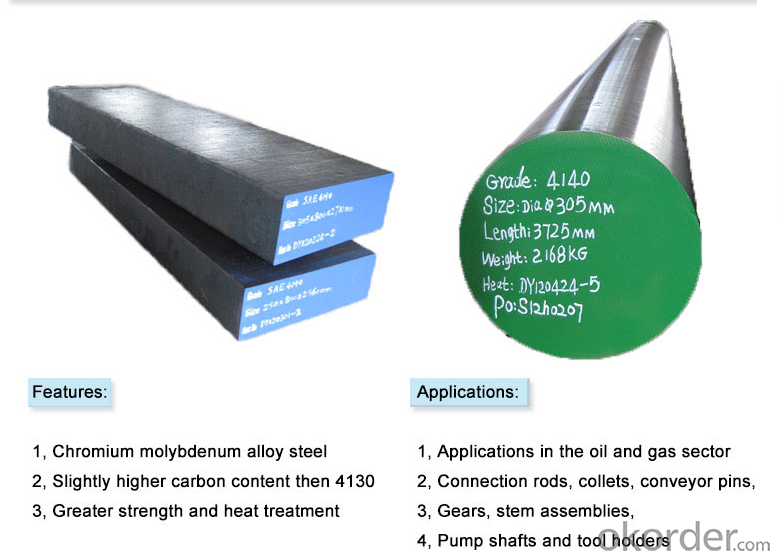

AISI 4140 Carbon Alloy Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

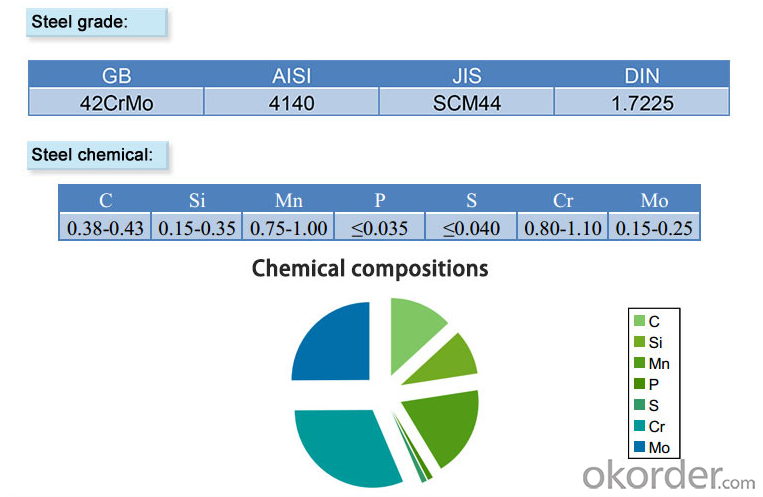

AISI 4140 Carbon Alloy Steel Round Bars

Product information:

- High Quanlity

-Various Type and Specification

-Competetive Price

- Perfect Service

-On Time Delivery

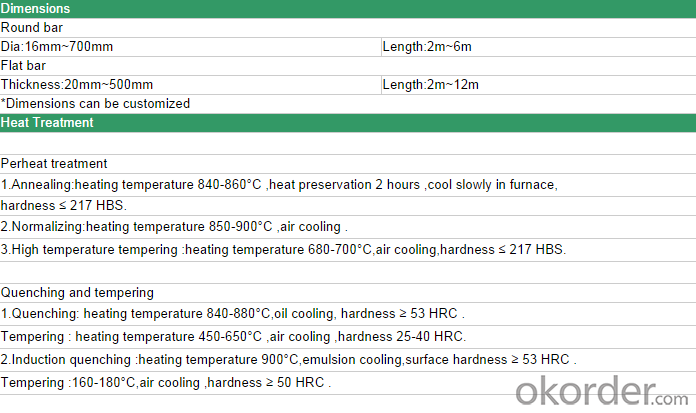

2.Process: EAF + LF + VD + Forged + Heat Treatment (optional)

3.Delivery condition: Hot forged +Rough machined (black surface after Q/T)+ Turned (optional)

4.Technical Data: According to the customer's requirement of Chemical Composition, Physical Properties and Mechanical Testing

5.Test: ultrasonic test according to SEP 1921-84 3 D/D

6.Material details will be as per agreed technical specifications

Other product show:

Our workshop show:

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: How does special steel contribute to the construction machinery industry?

- Special steel plays a crucial role in the construction machinery industry by providing high-strength and durable components. These components are essential for heavy-duty applications in construction machinery, such as excavators, bulldozers, cranes, and loaders. One of the key contributions of special steel to the construction machinery industry is its ability to withstand extreme stress and load-bearing requirements. Construction machinery often operates under severe conditions, including heavy loads, vibrations, and impacts. Special steel, with its excellent mechanical properties, can resist these conditions and maintain its structural integrity, ensuring the safety and reliability of the equipment. Moreover, special steel is often used in critical components of construction machinery, such as booms, buckets, tracks, and gears. These components are subjected to intense wear and tear due to constant use in harsh environments. Special steel, engineered with enhanced hardness and wear resistance, helps extend the lifespan of these components, reducing maintenance costs and downtime. Additionally, special steel provides superior corrosion resistance, which is vital for construction machinery used in humid or corrosive environments. By preventing rust and decay, special steel helps maintain the equipment's performance and longevity, ultimately increasing productivity and efficiency in construction projects. Furthermore, special steel enables the construction machinery industry to achieve innovative designs and advanced functionalities. Its versatility allows for the creation of complex shapes and precise tolerances, which are essential for optimizing the performance and efficiency of machinery. Special steel also enables the incorporation of advanced technologies, such as sensors and automation, enhancing the accuracy and productivity of construction equipment. In summary, special steel contributes significantly to the construction machinery industry through its ability to withstand extreme conditions, provide superior wear resistance and corrosion protection, and enable innovative designs. By utilizing special steel in the manufacturing process, construction machinery manufacturers can ensure the durability, safety, and efficiency of their equipment, ultimately benefiting the construction industry as a whole.

- Q: How does special steel perform in high-temperature corrosion?

- Special steel has been specifically engineered to excel in environments with high-temperature corrosion. Its exceptional properties grant it exceptional resistance against oxidation and corrosive reactions when subjected to elevated temperatures. The high chromium content found in special steel is a key factor contributing to its performance in high-temperature corrosion. Chromium creates a protective oxide layer, referred to as a passive film, which functions as a barrier against corrosive elements. This passive film remains stable even under high temperatures, successfully preventing oxidation and corrosion. Furthermore, special steel often incorporates additional alloying elements like nickel, molybdenum, and titanium, which further enhance its ability to resist high-temperature corrosion. These elements augment the steel's capacity to withstand aggressive chemical environments typically encountered in industrial processes involving high temperatures and corrosive substances. Moreover, special steel is renowned for its remarkable mechanical properties, which encompass high strength and toughness. These qualities enable the steel to endure the harsh conditions associated with high-temperature corrosion. Even when exposed to extreme temperatures and corrosive chemicals, it can retain its structural integrity and dimensional stability. In conclusion, special steel's exceptional resistance against high-temperature corrosion makes it the ideal choice for various applications in industries such as petrochemical, power generation, and aerospace. Its capacity to maintain performance and durability in challenging environments guarantees the longevity and reliability of equipment and structures, ultimately reducing maintenance and replacement expenses.

- Q: How does special steel contribute to the thermal conductivity of products?

- Special steel can significantly contribute to the thermal conductivity of products due to its unique composition and properties. Special steel is manufactured with specific alloying elements, such as chromium, nickel, molybdenum, or vanadium, which enhance its thermal conductivity. These alloys help in the efficient transfer of heat by increasing the free electron density within the steel. The presence of alloying elements in special steel improves its lattice structure, allowing for better heat transfer. The increased free electron density enables quick and efficient movement of thermal energy through the material. As a result, special steel can effectively conduct heat from one area to another, making it ideal for applications requiring high thermal conductivity. Furthermore, special steel is often processed using advanced techniques like heat treatment, forging, or rolling, which further optimize its properties. These processes refine the microstructure of the steel, reducing impurities and improving its thermal conductivity. The resulting steel product exhibits enhanced heat transfer capabilities and provides efficient thermal management. The high thermal conductivity of special steel makes it highly desirable for various industries and applications. It is commonly used in the manufacturing of heat exchangers, boilers, furnaces, and other thermal equipment where efficient heat transfer is crucial. Additionally, special steel is often employed in electrical appliances, such as stovetops or induction cookers, where rapid and uniform heat distribution is necessary. In summary, special steel contributes to the thermal conductivity of products by utilizing specific alloying elements and advanced processing techniques to enhance its heat transfer capabilities. Its high thermal conductivity makes it a valuable material for various industries, ensuring efficient heat management and optimal performance of thermal equipment and appliances.

- Q: What are the main factors affecting the heat resistance of special steel?

- The heat resistance of special steel is determined by several key factors, including its alloy composition, microstructure, and heat treatment. The addition of specific elements like chromium, nickel, molybdenum, and tungsten can enhance the steel's ability to withstand high temperatures by forming stable oxide layers on its surface, which protect against oxidation and corrosion. The microstructure of special steel also plays a role in its heat resistance. Factors like grain size, phase distribution, and the presence of precipitates can affect the steel's thermal stability. Fine-grained structures and a homogeneous phase distribution improve resistance to creep, while precipitates like carbides or intermetallic compounds strengthen the steel and prevent thermal softening. Heat treatment processes, such as quenching and tempering, have a significant impact on the heat resistance of special steel. Proper heat treatment optimizes the microstructure and enhances mechanical properties, including resistance to thermal degradation. Controlled quenching, for example, promotes the formation of a martensitic structure, which increases hardness and strength at high temperatures. Other factors that influence heat resistance include impurities, surface conditions, and environmental factors. Impurities like sulfur and phosphorus can reduce resistance to high temperatures by promoting brittle phase formation or oxidation. Surface conditions, such as roughness or cracks, can cause localized heating and accelerated degradation. Environmental factors like corrosive gases or high humidity can also promote oxidation or corrosion. In conclusion, the heat resistance of special steel is affected by alloy composition, microstructure, heat treatment, impurities, surface conditions, and environmental factors. Understanding and optimizing these factors are crucial for developing special steel with superior heat resistance for various industrial applications.

- Q: How does special steel perform in defense applications?

- Special steel is highly valued in defense applications due to its exceptional properties and performance. Firstly, special steel offers superior strength and toughness, making it highly resistant to impact and penetration. This strength is crucial in defense applications, as it provides protection against projectiles, explosives, and other threats. Additionally, special steel exhibits excellent hardness and wear resistance, making it ideal for applications such as armor plates, vehicle components, and protective gear. Its hardness enables it to withstand high-velocity impacts, while its wear resistance ensures durability and longevity even in extreme conditions. Moreover, special steel possesses excellent corrosion resistance, which is crucial in defense applications where exposure to harsh environments, saltwater, and chemicals is common. This corrosion resistance helps to maintain the structural integrity and performance of defense equipment, even in challenging conditions. Furthermore, special steel can be tailored to meet specific requirements, allowing for the customization of defense applications. By adjusting the alloy composition and heat treatment processes, special steel can be optimized for different purposes, such as ballistic armor, submarine hulls, or aircraft components. Overall, special steel's exceptional strength, toughness, hardness, wear resistance, corrosion resistance, and customizability make it an invaluable material in defense applications. It provides the necessary protection, durability, and reliability required to safeguard military personnel, vehicles, and equipment in various challenging scenarios.

- Q: What are the different methods of coating special steel?

- There are several different methods of coating special steel to enhance its performance and protect it from corrosion or other forms of damage. Some of the commonly used methods include: 1. Galvanizing: This method involves coating the steel with a layer of zinc, either through hot-dip galvanizing or electroplating. The zinc layer provides excellent corrosion resistance and acts as a sacrificial anode, protecting the steel from rusting. 2. Powder coating: In this process, a dry powder is applied electrostatically to the steel surface and then cured under heat. The powder melts and fuses into a protective layer that provides an attractive finish, as well as resistance to chipping, scratching, and corrosion. 3. Electroplating: This method involves immersing the steel in a solution containing a metal ion, such as chromium or nickel, and passing an electric current through it. The metal ions are then deposited onto the steel surface, forming a thin protective layer that improves corrosion resistance and provides a decorative finish. 4. Cladding: Cladding involves bonding a layer of corrosion-resistant material, such as stainless steel or titanium, to the surface of the special steel. This method provides enhanced resistance to corrosion, wear, and heat, while maintaining the strength and mechanical properties of the base steel. 5. Thermal spraying: This method involves heating a coating material, such as zinc or aluminum, to a molten or semi-molten state and then spraying it onto the steel surface using compressed air or a similar method. The sprayed material forms a protective layer that offers excellent corrosion resistance and can also provide other functional properties, such as thermal insulation or electrical conductivity. 6. Chemical conversion coating: This method involves treating the steel surface with a chemical solution that reacts with the surface to form a thin layer of a protective compound, such as phosphate or chromate. The conversion coating provides enhanced corrosion resistance and can also improve the adhesion of subsequent coatings. These are just a few of the many methods available for coating special steel. The choice of method depends on factors such as the desired properties, the intended application, and the budget constraints. It is important to select the most appropriate coating method to ensure the longevity and performance of the special steel.

- Q: How is corrosion-resistant steel different from regular steel?

- Corrosion-resistant steel, also known as stainless steel, differs from regular steel primarily due to the presence of chromium. Regular steel is prone to rust and corrosion when exposed to moisture and oxygen, while corrosion-resistant steel contains a minimum of 10.5% chromium, which forms a protective layer on its surface, preventing rust and corrosion. This additional element makes corrosion-resistant steel highly durable, long-lasting, and suitable for various applications where exposure to moisture or corrosive environments is a concern.

- Q: How is the quality of special steel ensured?

- The quality of special steel is ensured through a combination of rigorous testing, strict quality control measures, and adherence to international standards and specifications. Special steel producers employ various methods such as chemical analysis, mechanical testing, and non-destructive testing to verify the composition, strength, and integrity of the steel. Additionally, special steel manufacturers often have dedicated quality assurance teams that closely monitor the production process to identify any potential issues and ensure the final product meets the required specifications.

- Q: What are the casting methods for special steel?

- There are several casting methods used for special steel, including investment casting, sand casting, and centrifugal casting. Investment casting involves creating a wax pattern of the desired shape, which is then coated in ceramic and melted away, leaving a cavity that is filled with molten steel. Sand casting involves making a mold from a mixture of sand and a binder, and pouring molten steel into the mold cavity. Centrifugal casting utilizes centrifugal force to distribute molten steel into a mold, resulting in a more uniform casting with fewer defects.

- Q: What is the purpose of cold drawing in special steel production?

- The purpose of cold drawing in special steel production is to enhance the mechanical properties and improve the dimensional accuracy of the steel. Cold drawing involves pulling the steel through a die at room temperature, which increases its tensile strength, hardness, and surface finish. This process also allows for precise control over the final dimensions and shapes of the steel, making it suitable for various specialized applications.

Send your message to us

AISI 4140 Carbon Alloy Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords