1 8 X 1 4 Aluminum Bar Stock

1 8 X 1 4 Aluminum Bar Stock Related Searches

1 8 X 1 Aluminum Bar Stock 1 4 X 1 4 Aluminum Bar Stock 1 4 Inch Aluminum Bar Stock 1 8 Aluminum Bar Stock 1 2 X 3 4 Aluminum Bar Stock 3 4 X 3 8 Aluminum Bar Stock 1 4 Aluminum Bar Stock 1 X 2 Aluminum Bar Stock 1/4 X 1/4 Aluminum Bar Stock 1 Inch Aluminum Bar Stock 1 2 X 1 2 Aluminum Bar Stock 3/8 Aluminum Bar Stock 3/4 X 3/8 Aluminum Bar Stock 3 8 Aluminum Bar Stock 1/4 Aluminum Bar Stock 1 Aluminum Bar Stock 5 8 Aluminum Bar Stock 3 4 Aluminum Bar Stock 1 2 Aluminum Bar Stock Stock Aluminum Bar 1/2 X 3/4 Aluminum Bar Stock Aluminum Stock Bar 4 X 8 X 1 4 Aluminum Plate 1 4 Inch Aluminum Flat Stock Aluminum Bar Stock 1 2 3/4 Aluminum Bar Stock 3 Inch Aluminum Bar Stock Cutting Aluminum Bar Stock 2 Inch Aluminum Bar Stock 1/2 X 1/2 Aluminum Bar Stock1 8 X 1 4 Aluminum Bar Stock Supplier & Manufacturer from China

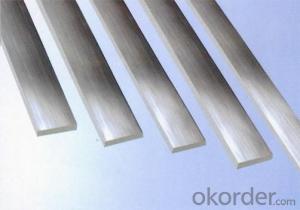

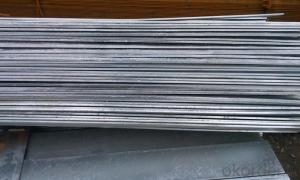

1 8 X 1 4 Aluminum Bar Stock is a type of aluminum material that comes in the dimensions of 18 inches by 14 inches, making it a versatile choice for various industrial applications. This product is known for its durability, lightweight properties, and corrosion resistance, which makes it suitable for a wide range of uses.The 1 8 X 1 4 Aluminum Bar Stock is commonly used in construction, aerospace, automotive, and other industries where high-strength, lightweight materials are required. It is ideal for manufacturing components such as brackets, frames, and structural supports, as well as for use in heat sinks, electrical enclosures, and other applications where thermal conductivity and electrical insulation are important. This product's versatility and strength make it a popular choice among engineers and designers.

Okorder.com is a reputable wholesale supplier of 1 8 X 1 4 Aluminum Bar Stock, offering a large inventory of this product to cater to the needs of various industries. With their extensive stock and competitive pricing, Okorder.com ensures that customers can access high-quality aluminum bar stock for their projects without compromising on performance or budget.

Hot Products