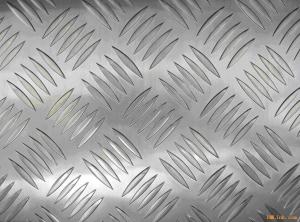

4x8 Aluminum Sheets - Five Bars Diamond Short Delivery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Five Bars,Diamond:

Five Bars,Diamond is widely used for decorative purposes in construction, packing and appliance. Five Bars,Diamond aluminum coil is also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of the Aluminum Five Bars,Diamond:

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminum Five Bars,Diamond

Alloy: | AA1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006 |

Temper: | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness: | 0.2-20mm |

Width: | 30mm-1500mm |

4. Production of Five Bars,Diamond

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: What is made when Aluminium and Hydrochloric Acid reacts? It makes a dense white smoke with a metallic odour in the gas. Could it be dissolved amounts of Aluminium Chloride or small amounts of unreacted Aluminium in the gas? Or could be that the Chlorine (in equilibrium with HCl and HClO) made chlorates and perchlorates of aluminium that give off odours?Don't tell me the gas isn't supposed to have an odour. I know what diatomic Hydrogen smells like. Nothing. That's the way it should be. But unfortunately, that's not the way it is.

- When aluminum reacts with hydrochloric acid heat is produced as well as aluminum chloride. This heat is warming up the HCl, which you should remember is a gas dissolved in water, a little of which evolves from the water. You're smelling HCl gas. There shouldn't be any dense white smoke, unless you've got an open container of ammonia nearby. In that case the smoke is particulate ammonium chloride, produced by the reaction in the air of HCl and NH3.

- Q: What is the best way to paint over aluminium siding? Should it be primed? What type of prime should be used? What type of paint should be used on this surface? What brush or roller should be used to apply the paint?

- the aluminum has to be washed first with I forget the name of it then it has to be primed with this blue primer that will make the paint stick to it and youcan use a latex paint call the paint dept or store and they can point you in the right direction the blue primer i used came from true value hardware store but i forget what it was called

- Q: What are the distinctions between standard aluminum windows and those that are custom-made?

- <p>Standard aluminum windows are mass-produced and come in set sizes and styles, offering affordability and quick installation. They may not fit perfectly into unique spaces and may lack customization options. Custom-made aluminum windows, on the other hand, are tailored to specific dimensions and design preferences, ensuring a perfect fit and enhanced aesthetics. They often come with more features and options, such as energy efficiency, security, and unique styling, but are typically more expensive and have a longer lead time for production and installation.</p>

- Q: What are the environmental benefits of using aluminum sheets?

- The usage of aluminum sheets is associated with numerous environmental advantages. To begin with, aluminum is a highly recyclable substance, meaning it can be recycled repeatedly without losing its quality or properties. This diminishes the need for mining and extracting new aluminum ore, which can lead to deforestation, destruction of habitats, and pollution of water and air. The recycling of aluminum sheets also demands much less energy compared to the production of new ones, resulting in reduced emissions of greenhouse gases and a smaller carbon footprint. Moreover, aluminum sheets are lightweight, making them a more sustainable option in comparison to materials like steel or plastic. Their utilization in various industries like automotive and aerospace can aid in reducing the overall weight of vehicles and aircraft, leading to improved fuel efficiency and lower emissions. This becomes particularly crucial in the context of climate change and the necessity to decrease our reliance on fossil fuels. Additionally, aluminum is resistant to corrosion, durable, and long-lasting, making it a sustainable choice for various applications. Its durability lessens the need for frequent replacements, thereby reducing waste generation. Furthermore, aluminum sheets can be employed in construction to enhance insulation, resulting in energy savings and diminished emissions of greenhouse gases. Lastly, aluminum is non-toxic and does not release harmful pollutants during its production or use. This renders it a safe material option for various applications, including food packaging and medical equipment. To summarize, the environmental benefits of using aluminum sheets include its recyclability, lightweight nature, energy efficiency, durability, and non-toxicity. By selecting aluminum sheets over other materials, we can contribute to the reduction of resource extraction, energy consumption, emissions of greenhouse gases, and generation of waste, while promoting a more sustainable and eco-friendly future.

- Q: Are aluminum sheets easy to clean?

- It is generally a simple task to clean aluminum sheets. Aluminum, being a non-porous material, has the advantage of not readily absorbing liquids or stains. Consequently, it is fairly easy to remove dirt, dust, or spills from the surface of aluminum sheets with the use of a moist cloth or sponge. Furthermore, aluminum's resistance to rust and corrosion means that no special cleaning agents or treatments are necessary. However, it is worth noting that abrasive cleaners or scrubbing pads should be avoided as they have the potential to scratch the aluminum surface. In summary, by regularly maintaining and employing proper cleaning techniques, aluminum sheets can be kept clean and in excellent condition for an extended period of time.

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: What are the thermal conductivity properties of aluminum sheets?

- Aluminum sheets have high thermal conductivity properties, meaning they are excellent conductors of heat. This allows them to efficiently transfer heat and distribute it evenly across their surface.

- Q: What are the fire resistance properties of aluminum sheets?

- Due to its high melting point and low thermal conductivity, aluminum sheets possess excellent fire resistance properties. Unlike other commonly used metals like steel, aluminum has a melting point of approximately 660 degrees Celsius, signifying its ability to withstand high temperatures without compromising its structural integrity. Moreover, aluminum's low thermal conductivity minimizes heat transfer, thereby hindering fire propagation and limiting the spread of heat to neighboring areas. In addition, aluminum does not release toxic gases or emit hazardous fumes when exposed to fire, rendering it a secure material for fire-prone environments. These fire-resistant characteristics have made aluminum sheets a preferred choice in numerous applications that prioritize fire safety, including aircraft, building, and automotive component construction.

- Q: What are the distinctions among various grades of aluminum sheets?

- <p>Yes, there are differences between different grades of aluminum sheets. These differences are primarily based on the alloy composition, which affects properties such as strength, formability, and corrosion resistance. For instance, 1000 series aluminum is pure and soft, making it ideal for general purposes. 2000 series is harder and stronger, often used in aerospace applications. 3000 series is known for its high resistance to corrosion and is used in marine applications. 5000 series offers good strength-to-weight ratio and is used in structural applications. 6000 series is known for its strength and is used in construction and industrial applications. Each grade has specific uses based on its unique characteristics.</p>

- Q: Are the aluminum sheets suitable for manufacturing aircraft wings?

- Yes, aluminum sheets are suitable for manufacturing aircraft wings. Aluminum is a lightweight and strong material that offers excellent structural integrity, making it a popular choice in the aerospace industry. It also possesses good corrosion resistance and can be easily formed into complex shapes, further contributing to its suitability for aircraft wing manufacturing.

Send your message to us

4x8 Aluminum Sheets - Five Bars Diamond Short Delivery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords