4x8 1/8 Aluminum Diamond Plate

4x8 1/8 Aluminum Diamond Plate Related Searches

4x8 1/8 Diamond Plate Aluminum 4x8 Aluminum Diamond Plate 1/8 4x8 1 8 Aluminum Diamond Plate 1/8 Aluminum Diamond Plate 4'X8' 4x8 1/4 Aluminum Diamond Plate 1/4 Aluminum Diamond Plate 4x8 4x8 1/4 Diamond Plate Aluminum 1 8 Aluminum Diamond Plate 4 X8 4x8 Aluminum Diamond Plate 1 8 4x8 Aluminum Diamond Plate Aluminum Diamond Plate 4x8 4x8 1 4 Aluminum Diamond Plate 4 X 8 Aluminum Diamond Plate 4x8 Diamond Plate Aluminum Diamond Plate Aluminum 4x8 4 8 Aluminum Diamond Plate 4 X 8 Diamond Plate Aluminum 4x8 Aluminum Diamond Plate 3/16 4x8 3/16 Aluminum Diamond Plate 1/8 Aluminum Diamond Plate 4x8 Sheet Aluminum Diamond Plate 1/8 Diamond Plate Aluminum 1/8 Inch Aluminum Diamond Plate Black Aluminum Diamond Plate 4x8 4x8 3 16 Aluminum Diamond Plate 1/4 Aluminum Plate 4x8 1 8 Aluminum Diamond Plate 4x8 Sheet Diamond Plate Aluminum 1/8 Inch Diamond Plate Aluminum Aluminum Diamond Plate 4x8 Sheet4x8 1/8 Aluminum Diamond Plate Supplier & Manufacturer from China

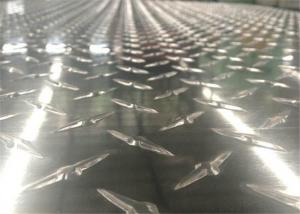

The 4x8 1/8 Aluminum Diamond Plate is a type of metal sheet known for its slip-resistant surface and durability. This product features a diamond-shaped pattern that provides excellent traction, making it an ideal choice for various applications where safety and stability are paramount. The aluminum material ensures that the plates are lightweight yet strong, offering a reliable solution for both indoor and outdoor use.The 4x8 1/8 Aluminum Diamond Plate is widely used in a range of industries, including construction, automotive, and marine, where its non-slip properties and corrosion resistance are highly valued. It is commonly applied as flooring in workshops, walkways, and ramps to minimize the risk of accidents caused by slipping. Additionally, its aesthetic appeal makes it a popular choice for decorative purposes, such as in the creation of unique furniture or architectural features. The versatility of this product allows it to be tailored to specific needs, whether it's for functional or decorative purposes.

Okorder.com is a leading wholesale supplier of the 4x8 1/8 Aluminum Diamond Plate, offering a vast inventory to meet the demands of various customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the products are sourced from reputable manufacturers and are available at competitive prices. Their extensive inventory allows for quick turnaround times, making them an ideal choice for businesses looking to stock up on this versatile and essential product.

Hot Products