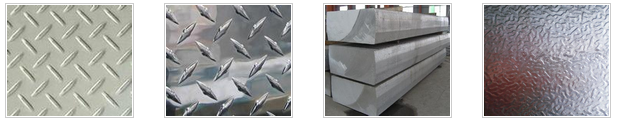

Aluminium Tear Plates, Bright Diamond

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Tear Plates, Bright Diamond :

Aluminium Tear Plates, Bright Diamond is widely used for decorative purposes in construction, packing and appliance. Aluminium Tear Plates, Bright Diamond is also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of Aluminium Tear Plates, Bright Diamond :

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminium Tear Plates, Bright Diamond

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm-1500mm

4. Production of Aluminium Tear Plates, Bright Diamond

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Which is better, metal ceiling, galvanized steel sheet and aluminum sheet?

- Personally feel that the aluminum plate is good, aluminum corrosion resistance, galvanized sheet corrosion.

- Q: Okay, so i swallowed some aluminum foil like the size of a quarter from my fruit rollup wrapper, ha don't ask why? but my stomach KINDA hurts right now...like 2 minutes later.. Could this have done any damage to me.?

- lol... You should be fine. But it may hurt a little coming out the other end? I don't know. One thing I do know: I swallowed a penny when I was a child and never had any trouble.

- Q: Are the aluminum sheets suitable for manufacturing aircraft fuselages?

- Yes, aluminum sheets are suitable for manufacturing aircraft fuselages. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and easy formability. It provides structural integrity while keeping the weight of the fuselage low, making it an ideal material choice for aircraft manufacturing.

- Q: What are the different types of alloys used for painted aluminum sheets?

- There are several different types of alloys that are commonly used for painted aluminum sheets. One of the most popular alloys is 3003, which is known for its excellent corrosion resistance and high formability. This alloy is often used for applications where a smooth surface finish is desired, such as in the automotive industry. Another commonly used alloy is 5052, which offers a higher strength compared to 3003. This alloy is often used in marine and architectural applications due to its excellent corrosion resistance and ability to withstand harsh environments. It is also known for its good weldability and formability. Additionally, 6061 is a popular alloy choice for painted aluminum sheets. This alloy is known for its high strength and excellent machinability. It is often used in structural applications, such as in the manufacturing of aircraft parts and automotive components. Other alloys that are sometimes used for painted aluminum sheets include 2024, 5754, and 7075. These alloys offer specific properties that make them suitable for certain applications, such as high strength or improved corrosion resistance. Overall, the choice of alloy for painted aluminum sheets depends on the specific requirements of the application, such as the desired strength, corrosion resistance, and formability.

- Q: Can aluminum sheets be easily bent or shaped?

- Yes, aluminum sheets can be easily bent or shaped due to their malleability. Aluminum is a soft and lightweight metal that possesses excellent formability characteristics, making it highly suitable for various shaping processes. It can be easily bent, folded, or formed into different shapes using a variety of techniques such as press braking, roll forming, or stretch forming. The malleability of aluminum allows it to be easily molded into intricate shapes without cracking or breaking. Additionally, aluminum's low melting point makes it possible to heat and shape it further using processes like hot bending or thermoforming. Overall, aluminum sheets offer great flexibility and ease of shaping, making them a popular choice in industries such as automotive, aerospace, construction, and manufacturing.

- Q: Can 101 aluminum sheets be customized in terms of size and thickness?

- Yes, 101 aluminum sheets can be customized in terms of size and thickness. Aluminum sheets can be cut to the desired size and thickness using various cutting techniques such as shearing, sawing, or laser cutting. Additionally, aluminum sheets can also be rolled or stretched to achieve the desired thickness. Customizing the size and thickness of aluminum sheets allows them to be tailored to specific applications or requirements.

- Q: What is the weight of aluminum sheets per square foot?

- The weight per square foot of aluminum sheets may differ depending on the sheet's thickness or gauge. Typically, a 1/8 inch thick aluminum sheet weighs approximately 1.9 pounds per square foot. Nevertheless, thinner sheets tend to be lighter, whereas thicker sheets can be heavier. It is crucial to take into account the precise thickness of the aluminum sheet when calculating its weight per square foot.

- Q: Can aluminum sheets be used for signage?

- Yes, aluminum sheets can be used for signage. Aluminum is a versatile and durable material that is commonly used in the sign-making industry. It is known for its lightweight yet sturdy properties, making it ideal for outdoor and indoor signage. Aluminum sheets are resistant to corrosion, rust, and fading, ensuring that the signage will last for a long time. Additionally, aluminum can be easily cut and shaped into various sizes and designs, allowing for creative and customized signage solutions. The material also provides a smooth surface that can be painted, printed, or laminated with graphics and text, making it highly versatile for different signage applications. Overall, aluminum sheets are a popular choice for signage due to their durability, versatility, and aesthetic appeal.

- Q: What are the cost considerations when purchasing aluminum sheets?

- There are various factors to keep in mind when buying aluminum sheets that affect their cost. Firstly, the price of aluminum sheets is determined by the current market conditions. Factors such as supply and demand, global economic conditions, and geopolitical events influence the price. Therefore, it is important to stay updated on market trends and fluctuations to ensure an informed purchasing decision. Another consideration is the quantity of aluminum sheets needed. Buying in bulk or larger quantities often results in lower costs per unit. However, it is crucial to accurately assess the required quantity to avoid excess inventory and unnecessary expenses. Additionally, the grade and quality of aluminum sheets can impact their price. Aluminum sheets come in various grades, each with specific properties and performance characteristics. Higher-grade aluminum sheets, which have superior strength or corrosion resistance, tend to be more expensive. It is important to evaluate the project's specific requirements to determine the appropriate grade of aluminum sheets needed. Transportation costs should also be taken into account. Depending on the supplier's location and the quantity ordered, shipping expenses can vary significantly. Exploring different shipping options and negotiating favorable terms can help minimize transportation costs. Lastly, additional costs such as processing, finishing, and customization should be considered. Some projects may require services like cutting, bending, or coating the aluminum sheets, which can add to the overall cost. However, these services may be necessary to meet specific project requirements. In conclusion, it is crucial to consider the current market price, required quantity, grade and quality, transportation costs, and any additional processing or customization needs when purchasing aluminum sheets. By carefully evaluating these factors, one can make an informed decision and ensure the best value for their investment.

- Q: a dream I had where the carbon element was extracted from aluminum and ploished it became transparent, it was bendable and you could puncher it with out breaking it ?

- Aluminium is an element! Elements are pure substances, therefore aluminium doesn't contain any carbon. What do you mean?

Send your message to us

Aluminium Tear Plates, Bright Diamond

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords