Painting Aluminum Diamond Plate

Painting Aluminum Diamond Plate Related Searches

Painting Aluminum Plate Polishing Aluminum Diamond Plate Polishing Diamond Plate Aluminum Aluminum Diamond Plate Polish Diamond Plate Aluminum Polish Polished Aluminum Diamond Plate Welding Aluminum Diamond Plate Colored Aluminum Diamond Plate Diamond Plate Aluminum Sheeting Buy Aluminum Diamond Plate Painting Aluminum Foil Art Aluminum Diamond Plate Panels Photo On Aluminum Plate Cosmetic Aluminum Diamond Plate Bending Aluminum Diamond Plate Aluminum Diamond Plate For Sale Bending Diamond Plate Aluminum Anodized Aluminum Diamond Plate Painting On Aluminum Foil Aluminum Diamond Plate Trim Etching On Aluminum Plate Forming Aluminum Plate Aluminum Diamond Deck Plate Painting With Aluminum Foil Aluminum Foil Painting Decorative Aluminum Plate Diamond Plate Aluminum Trim Sheet Of Diamond Plate Aluminum Embossed Aluminum Diamond Plate Aluminum Black Diamond PlatePainting Aluminum Diamond Plate Supplier & Manufacturer from China

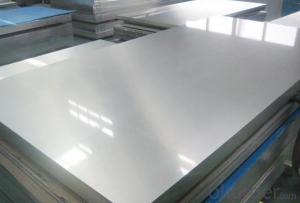

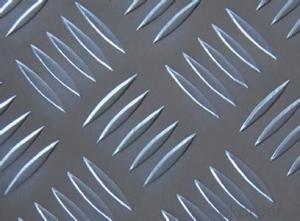

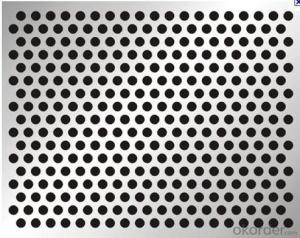

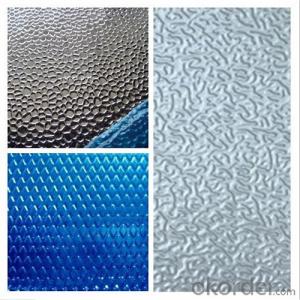

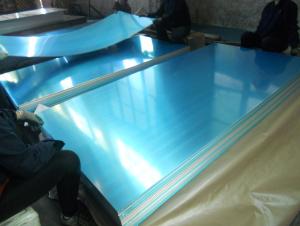

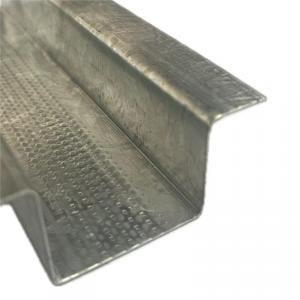

Painting Aluminum Diamond Plate is a type of aluminum sheet material that features a diamond-shaped pattern on its surface, offering both aesthetic appeal and enhanced slip resistance. This product is widely recognized for its durability, corrosion resistance, and light weight, making it an ideal choice for various applications.The Painting Aluminum Diamond Plate is commonly used in a variety of industries, including construction, transportation, and manufacturing. It is particularly popular in applications where a non-slip surface is required, such as on stair treads, ramps, flooring, and walkways. Additionally, its decorative properties make it suitable for use in interior design and architectural projects, where a modern and sleek appearance is desired.

Okorder.com is a leading wholesale supplier of Painting Aluminum Diamond Plate, boasting a large inventory that caters to the diverse needs of customers worldwide. By offering competitive prices and reliable service, Okorder.com ensures that businesses and individuals can access high-quality Painting Aluminum Diamond Plate for their projects.

Hot Products