Wholesale 201 Stainless Steel Sheet Embossed Sheets Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless steel which can be produced in different chemical, physical and mechanical properties, have high corrosion and heat resistance, mechanical strength, manufacturing ease, aesthetic appearance hygienic and long lasting properties.

STANDARDS

ASTM A240/A240M,ASME A240/A240,EN 10088-2, EN10028-7,JIS G 4305

| Decoration Stainless Steel Sheet / Plate | |

| Size | Thickness 0.02mm-3mm, Width and Length can be customized |

| Grade | SUS 201, 202, 304L/H, 316L/H, 321/H, 317/H, 347/H, 310S, 430, 409/L, 31803, 32750, 32760, etc |

| Standard | JIS,EN,ASTM,AISI |

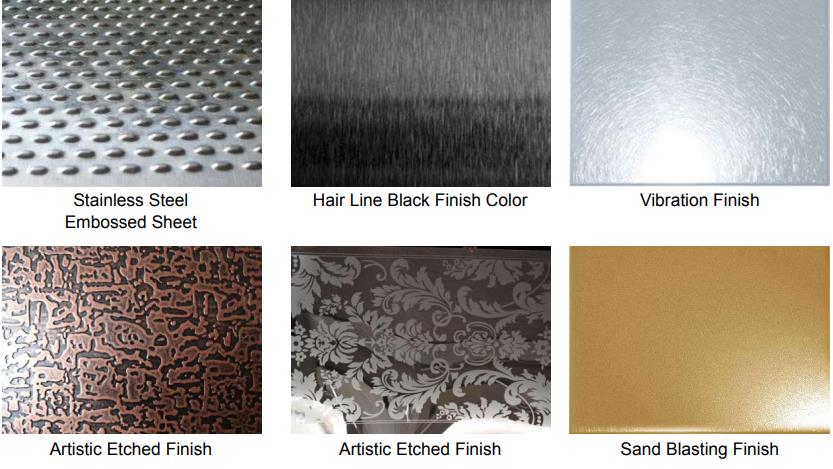

| Finish | 2B, HL, NO.4, BA, Mirror, Embossed, Colored, Vibration, Sand blasting, Artistic etched etc. |

| Application | Elevator, Carbin Decoration, Building Decoration, Architectural Decoration, Kitchen Decoration |

Stainless Steel Sheet Series

Stainless Steel Polished Sheet (8K Mirror, Hairline, Grit 240,320)

Embossed Stainless Steel Sheet

Etched Stainless Steel Sheet,

PVD Colored Stainless Steel Sheet,

Perforated Stainless Steel Plate

Chequered Stainless Steel Sheet

Packaging & Shipping

Application

Kitchen, Subway, Hospital, Door, Frame of Door, Structure, Machine, Pipe, Utensil, Internal Decoration of Elevator.

- Q: How do you restore the shine on a stainless steel sheet?

- To restore the shine on a stainless steel sheet, you can follow a few simple steps. First, make sure the surface is clean by wiping away any dirt or debris using a soft cloth or sponge and a mild detergent mixed with warm water. Rinse off the soap residue and dry the sheet thoroughly. Next, apply a small amount of stainless steel cleaner or polish to a clean, soft cloth. Gently rub the cleaner in a circular motion onto the stainless steel sheet, focusing on any areas with visible marks or dullness. Be sure to follow the manufacturer's instructions for the cleaner or polish you are using. After applying the cleaner, let it sit on the surface for a few minutes to allow it to work its magic. Then, using a clean portion of the cloth, buff the stainless steel sheet using circular motions until the shine starts to appear. Continue this process until you are satisfied with the results. If you don't have a specialized stainless steel cleaner or polish, you can also use some household items to restore the shine. For example, you can mix baking soda with water to form a paste and apply it to the sheet. Gently rub the paste onto the surface using a soft cloth and rinse it off thoroughly. Additionally, you can use vinegar or lemon juice to remove any stains or spots. Apply a small amount of vinegar or lemon juice to a cloth and rub it onto the stainless steel sheet, then rinse it off and dry it thoroughly. Remember to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This will ensure that it doesn't cause any damage or discoloration.

- Q: What are the different welding techniques used for stainless steel sheets?

- Various welding techniques are commonly employed for stainless steel sheets, each offering distinct advantages and considerations. 1. TIG Welding (Gas Tungsten Arc Welding): TIG welding, a versatile and precise method, proves suitable for thin stainless steel sheets. It involves using a non-consumable tungsten electrode to generate an electric arc that melts and fuses the metals. High-quality welds with minimal heat distortion and excellent aesthetic appearance are ensured. 2. MIG Welding (Gas Metal Arc Welding): MIG welding, known for its efficiency and user-friendliness, is a popular choice for stainless steel sheets. It employs a consumable electrode wire and an inert gas shield to protect the weld from atmospheric contamination. MIG welding exhibits faster speed than TIG welding and performs well on thicker stainless steel sheets. 3. Spot Welding: Joining two stainless steel sheets together, spot welding applies pressure and heat using electrodes. This technique finds common use in applications where a continuous seam is unnecessary, such as in automotive manufacturing or appliance production. 4. Plasma Arc Welding: Similar to TIG welding, plasma arc welding employs a more concentrated arc produced by a constricted nozzle. This technique allows for deeper penetration on stainless steel sheets, making it suitable for thicker materials or specialized applications. 5. Laser Welding: Laser welding, a precise and rapid technique, employs a high-powered laser beam to melt and join stainless steel sheets. It offers exceptional control over the welding process and proves suitable for thin to medium thickness stainless steel sheets. However, laser welding may require specialized equipment and expertise. The choice of welding technique depends on various factors, including the thickness of the stainless steel sheets, desired weld quality, production speed, and equipment availability. Each technique possesses its own advantages and limitations.

- Q: Are stainless steel sheets resistant to impact?

- Stainless steel sheets possess a general resistance to impact. Renowned for their robustness and durability, stainless steel is capable of enduring substantial force without deformation or fracture. This quality renders stainless steel sheets highly sought after in the construction, automotive, and aerospace sectors, where impact resistance is imperative. Moreover, the impact resistance of stainless steel sheets can be augmented by subjecting them to additional hardening or tempering processes, tailored to meet the precise demands of the application at hand.

- Q: What kind of welding rod is used for 310S stainless steel?

- A132 welding electrodes are used to weld important corrosion resistant, Ti stabilized 0Cr19Ni10Ti stainless steels.A137 is an Cr19Ni10Nb stainless steel electrode with an alkaline coating and a low carbon content containing Nb stabilizer. It is used for welding important corrosion resistant Ti stabilized stainless steel 0Cr19Ni11Ti.310S stainless steel is austenitic chromium nickel stainless steel, with good oxidation resistance, corrosion resistance, acid and alkali resistance, high temperature resistance. Mainly used in petroleum, electronics, chemical, pharmaceutical, textile, food, machinery, construction, nuclear power, aerospace, military and other industries.

- Q: Can stainless steel sheets be used in medical applications?

- Yes, stainless steel sheets can be used in medical applications. Stainless steel is a popular choice in the medical field due to its excellent corrosion resistance, durability, and ease of sterilization. It is widely used in medical devices, surgical instruments, and implantable components due to its ability to withstand harsh sterilization processes such as autoclaving, which is crucial for maintaining cleanliness and preventing infections. Additionally, stainless steel is biocompatible, meaning it does not react with the body's tissues and does not cause any harm or adverse reactions. Overall, stainless steel sheets are a reliable and versatile material for various medical applications.

- Q: Are stainless steel sheets resistant to heat and high temperatures?

- Yes, stainless steel sheets are highly resistant to heat and high temperatures. They can withstand extreme temperatures without warping, melting, or losing their structural integrity.

- Q: What is the electrical resistance of stainless steel sheets?

- The electrical resistance of stainless steel sheets can vary depending on factors such as the grade of stainless steel, its thickness, and the temperature at which it is being used. However, in general, stainless steel is considered to have a relatively high electrical resistance compared to other metals.

- Q: What is the difference between cold rolled and hot rolled stainless steel sheets?

- The main difference between cold rolled and hot rolled stainless steel sheets lies in the manufacturing process. Cold rolled stainless steel sheets are produced by rolling the steel at a lower temperature, which results in a smoother and more polished finish. Hot rolled stainless steel sheets, on the other hand, are produced by rolling the steel at a higher temperature, which makes them less smooth and less polished. Additionally, hot rolled sheets tend to have a thicker gauge compared to cold rolled sheets.

- Q: What are the different types of stainless steel sheet textures available?

- There are several different types of stainless steel sheet textures available, each offering a unique aesthetic and functional appeal. Some of the commonly used textures include: 1. Brushed: This texture is achieved by brushing the stainless steel surface with abrasive materials in a unidirectional pattern. It creates a smooth, satin-like finish that is commonly seen in kitchen appliances and decorative applications. 2. Mirror: As the name suggests, this texture creates a highly reflective and mirror-like surface. It is achieved by polishing the stainless steel sheet using progressively finer abrasive materials until a reflective finish is obtained. Mirror-textured stainless steel sheets are often used in architectural and decorative applications. 3. Embossed: This texture involves imprinting patterns or designs onto the stainless steel sheet using embossing rollers. The raised patterns add depth and visual interest to the surface, making it a popular choice for interior design applications such as wall cladding or elevator panels. 4. Perforated: This texture involves creating a pattern of holes or perforations on the stainless steel sheet. It allows for the passage of light, air, or liquids while adding a decorative element to the surface. Perforated stainless steel sheets are commonly used in architectural, interior design, and filtration applications. 5. Etched: This texture is achieved by chemically etching the stainless steel surface using acid or other corrosive substances. The etching process creates a pattern or design on the surface, resulting in a visually appealing, textured finish. Etched stainless steel sheets are often used in decorative applications such as signage, elevator doors, or wall panels. 6. Hammered: This texture involves using hammers or other tools to create a hammered or dimpled pattern on the stainless steel sheet. It adds a rustic, textured look to the surface and is commonly used in architectural and decorative applications. These are just a few examples of the different types of stainless steel sheet textures available. Depending on the desired aesthetic and functional requirements, there are various other textures and finishes that can be applied to stainless steel sheets to achieve different looks and effects.

- Q: What are the benefits of using patterned stainless steel sheets in interior design?

- There are numerous advantages to utilizing patterned stainless steel sheets in interior design. To begin, these sheets bring a distinct and contemporary aesthetic to any area. The patterns etched onto the stainless steel come in a variety of designs, ranging from geometric shapes to intricate motifs, adding a touch of elegance and visual interest to walls, ceilings, or furniture. This can enhance the overall ambiance of a room and make it truly stand out. Additionally, patterned stainless steel sheets are incredibly durable and long-lasting. Stainless steel is well-known for its strength and resistance to corrosion, making it an ideal material for interior design applications. These sheets can withstand daily wear and tear, making them suitable for high-traffic areas such as restaurants, hotels, or public spaces. Furthermore, patterned stainless steel sheets require minimal maintenance. Unlike other materials, stainless steel is easy to clean and does not require special care or regular maintenance. A simple wipe with a damp cloth or the use of mild cleaning agents is sufficient to keep the sheets looking pristine. This makes them a practical choice for interior design, especially in areas where hygiene is crucial. Moreover, patterned stainless steel sheets offer design versatility. They can be used in various applications, including wall cladding, room dividers, backsplashes, or even as decorative accents. With a wide range of patterns and finishes available, designers have the freedom to create unique and customized looks to suit any style or theme. Lastly, incorporating patterned stainless steel sheets into interior design is environmentally friendly. Stainless steel is a recyclable material, meaning it can be reused or repurposed without causing harm to the environment. By incorporating sustainable materials into interior design, we contribute to reducing waste and promoting eco-conscious practices. In conclusion, the use of patterned stainless steel sheets in interior design provides benefits such as aesthetic appeal, durability, low maintenance requirements, versatility, and environmental friendliness. These sheets offer a practical and visually pleasing solution to elevate the design of any space.

Send your message to us

Wholesale 201 Stainless Steel Sheet Embossed Sheets Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords